Method and corrosive liquid for making texture surface of monocrystalline silicon

A technology of etching liquid and monocrystalline silicon, which is applied in chemical instruments and methods, crystal growth, and final product manufacturing, etc., can solve the problems of single crystal silicon texture reduction, use limitation, unsatisfactory short-circuit current, etc., and achieve high photoelectric conversion Efficiency, effect of high short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The corrosion solution used in this embodiment includes, by mass concentration, 0.1% NaOH, 8% isopropanol, 0.3% sodium lactate, 1% urea, and the balance water.

[0047] The operation steps are as follows:

[0048] 1) Throwing the monocrystalline silicon wafer into a NaOH solution with a temperature of 65° C. and a concentration of 10% for rough polishing to remove the mechanically damaged layer. The time for rough polishing is 1.5 minutes;

[0049]2) Rinse the roughly polished monocrystalline silicon with pure water to remove surface residues;

[0050] 3) Throwing monocrystalline silicon into an etching solution at a temperature of 78°C to make a suede surface, and the etching time is 20 minutes;

[0051] 4) Rinse the corroded monocrystalline silicon with pure water to remove surface residues;

[0052] 5) Spin the monocrystalline silicon wafer to dry in a spin dryer.

[0053] Observe the surface morphology of single crystal silicon with SEM, such as figure 1 shown. ...

Embodiment 2

[0056] The corrosion solution used in this embodiment includes, by mass concentration, 0.5% NaOH, 5% isopropanol, 0.5% sodium lactate, 2% urea, and the balance water.

[0057] Operation steps are identical with embodiment 1.

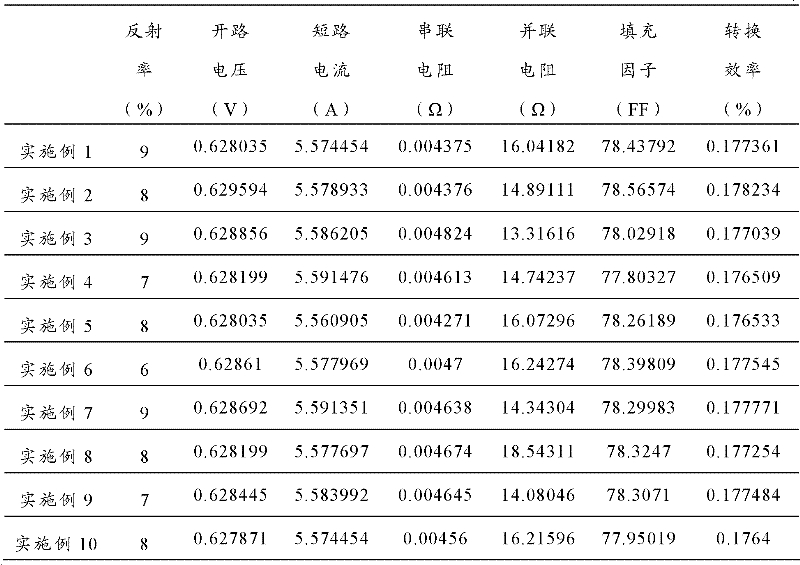

[0058] The monocrystalline silicon wafers were assembled into batteries, and the measured electrical properties are listed in Table 1.

Embodiment 3

[0060] The corrosion solution used in this embodiment includes, in terms of mass concentration: 0.2% NaOH, 6% isopropanol, 0.25% sodium lactate, 1% urea, and the balance water.

[0061] Operation steps are identical with embodiment 1.

[0062] The monocrystalline silicon wafers were assembled into batteries, and the measured electrical properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com