Non-hydrolytic sol-gel method for preparing high- dispersity nano alumina

A nano-alumina, high-dispersibility technology, applied in the direction of alumina/aluminum hydroxide, nanotechnology, etc., can solve the problem of less nano-alumina, achieve small particle size, small industrial amplification factor, and uniform particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

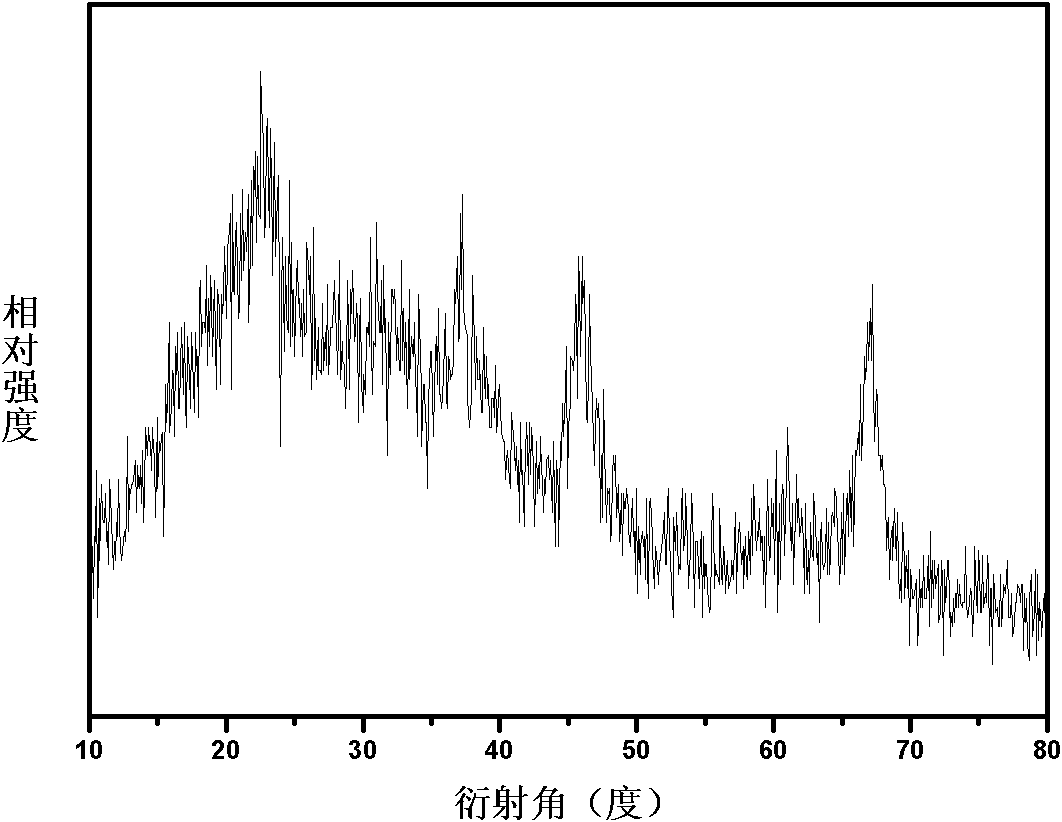

Image

Examples

Embodiment 1

[0024] The non-aqueous sol-gel preparation of highly dispersed nano-alumina is prepared by a low-temperature non-aqueous sol-gel method, and the preparation steps are as follows:

[0025] Step 1: Add aluminum salt hexahydrate aluminum trichloride, anhydrous aluminum trichloride, Aluminum nitrate nonahydrate, aluminum sulfate, aluminum ammonium sulfate dodecahydrate or aluminum isopropoxide, prepared as a precursor with an aluminum salt amount of 0.5-1.5 mol / liter;

[0026] Step 2: Solvothermally treat the precursor obtained in Step 1 at a temperature of 100-200° C. for 6-48 hours;

[0027] Step 3: After the reaction in step 2 is completed, wash the sample with absolute ethanol, and dry the product in the air at 50°C for 12 hours to obtain a highly dispersible nano-alumina powder;

Embodiment 2

[0029] The non-aqueous sol-gel preparation of highly dispersed nano-alumina is prepared by a low-temperature non-aqueous sol-gel method, and the preparation steps are as follows:

[0030] Step 1: Add aluminum salt hexahydrate aluminum trichloride, anhydrous aluminum trichloride, Aluminum nitrate nonahydrate, aluminum sulfate, aluminum ammonium sulfate dodecahydrate or aluminum isopropoxide, prepared as a precursor with an aluminum salt amount of 0.5-1.2 mol / liter;

[0031] Step 2: Solvothermally treat the precursor obtained in Step 1 at a temperature of 100-180° C. for 18-36 hours;

[0032] Step 3: After the reaction in step 2 is completed, wash the sample with absolute ethanol, and dry the product in the air at 50°C for 12 hours to obtain a highly dispersible nano-alumina powder;

Embodiment 3

[0034] Preparation of highly dispersible nano-alumina powder, the preparation steps are:

[0035] Step 1: adding anhydrous aluminum trichloride to benzyl alcohol to form a precursor whose amount of anhydrous aluminum trichloride is 0.5 mol / liter;

[0036] Step 2: Solvothermally treat the precursor in step 1 at a temperature of 180°C for 20 hours;

[0037] Step 3: after step 2, centrifuge, and wash the centrifuged product with ethanol for 3 times, and dry the product in air at 50°C for 12 hours to obtain a highly dispersible nano-alumina powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com