Method for cutting golden finger of flexible circuit board by ultraviolet laser

A flexible circuit and gold finger technology, applied in the field of UV laser cutting of flexible circuit board gold fingers, can solve problems such as hidden dangers, poor incision quality, short circuit of thin copper sheets of gold fingers, etc., to avoid thermal damage and improve cutting quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

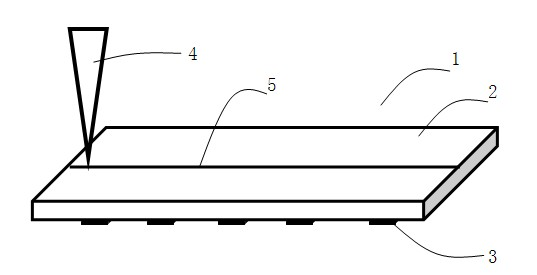

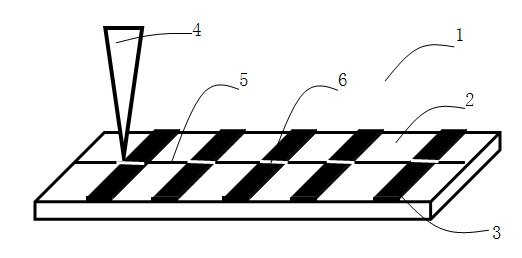

Image

Examples

example 1

[0019] The present invention adopts the Awave-355-8W-25K all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, with an output wavelength of 355nm, pulse energy from 0 to 500μJ, and a frequency of 10 to 100kHz for cutting FPC gold fingers. The thickness of the PI base material of the FPC gold finger is 120 microns, and the thickness of the conductive copper foil is 18 microns. The processing parameters of the blind holes drilled by the ultraviolet laser are shown in Table 1. The cutting quality of the FPC golden finger obtained by adopting the invention achieves the effects of no heat damage, carbonization and debris in the PI cut.

[0020] Table I

[0021]

example 2

[0023] The present invention adopts the Awave-355-8W-25K all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, with an output wavelength of 355nm, pulse energy from 0 to 500μJ, and a frequency of 10 to 100kHz for cutting FPC gold fingers. The thickness of the PI base material of the FPC gold finger is 200 microns, and the thickness of the conductive copper foil is 20 microns. The processing parameters of the blind holes drilled by the ultraviolet laser are shown in Table 2. The cutting quality of the FPC golden finger obtained by adopting the invention achieves the effects of no heat damage, carbonization and debris in the PI cut.

[0024] Table II

[0025]

example 3

[0027] The present invention adopts the Awave-355-8W-25K all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, with an output wavelength of 355nm, pulse energy from 0 to 500μJ, and a frequency of 10 to 100kHz for cutting FPC gold fingers. The thickness of the PI base material of the FPC gold finger is 300 microns, and the thickness of the conductive copper foil is 25 microns. The processing parameters of the blind holes drilled by the ultraviolet laser are shown in Table 2. The cutting quality of the FPC golden finger obtained by adopting the invention achieves the effects of no heat damage, carbonization and debris in the PI cut.

[0028] Table three

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com