Nifedipine double-layer osmotic pump medicinal composition and preparation technology thereof

An osmotic pump and composition technology, applied in the field of single-chamber double-layer osmotic pump controlled-release pharmaceutical composition and its preparation, can solve difficult-to-control controlled-release tablet batch-to-batch consistency, drug release time lag, tablet core Problems such as slow hydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

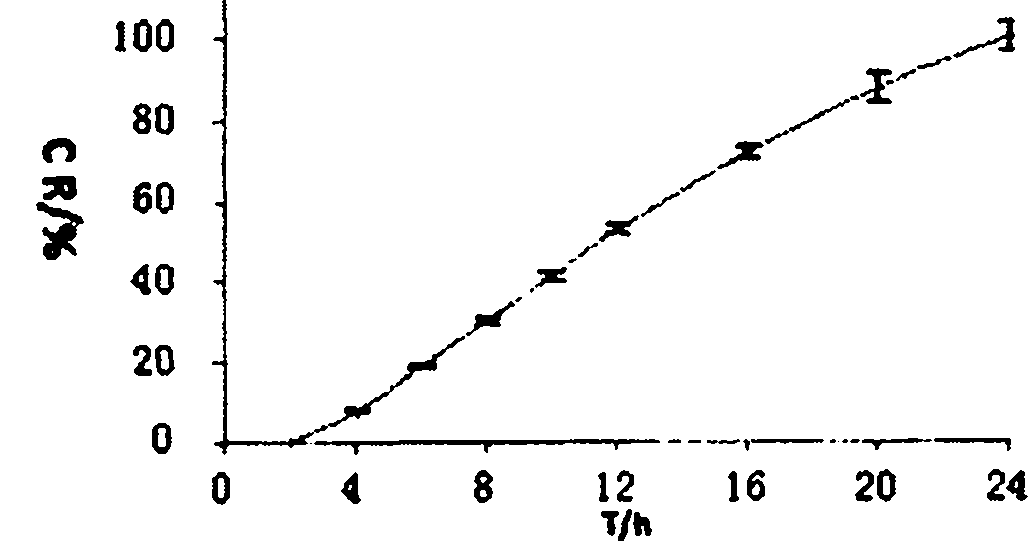

Image

Examples

Embodiment 1

[0043] (1) Drug-containing layer

[0044]

[0045]

[0046] Prepare soft materials with 10% PVPK30 ethanol solution

[0047] (2) booster layer

[0048] Polyoxyethylene (molecular weight 5 million) 60g

[0049] HPMC (K4M) 12.4g

[0051] Iron Oxide Red 1.72g

[0052] Prepare soft materials with 10% PVPK30 ethanol solution

[0053] (3) Prescription of coating solution

[0054] Cellulose acetate (398-10NF) 60g

[0055] PEG 4000 6g

[0056] DEP10%

[0057] Proper amount of acetone

[0058] Preparation:

[0059] 1. Preparation of drug-containing layer particles:

[0060]Grind nifedipine, polyoxyethylene (molecular weight: 200,000) and sodium lauryl sulfate into fine powder, pass through a 100-mesh sieve, mix well, make a soft material with 10% povidone ethanol solution, pass through a 40-mesh sieve Granules, dried at 45°C for 12 hours, added with 1% magnesium stearate and 0.5% silicon dioxide, and mixed evenly to obtain drug-containing ...

Embodiment 2

[0070] (1) Drug-containing layer

[0071]

[0072] Prepare soft materials with 10% PVPK30 ethanol solution

[0073] (2) booster layer

[0074] Polyoxyethylene (molecular weight 5 million) 60g

[0075] HPMC (K4M) 12.4g

[0077] Iron Oxide Red 1.72g

[0078] Prepare soft materials with 10% PVPK30 ethanol solution

[0079] (3) Prescription of coating solution

[0080] Cellulose acetate (398-10NF) 60g

[0081] PEG 4000 6g

[0082] DEP10%

[0083] Proper amount of acetone

[0084] Preparation:

[0085] 1. Preparation of drug-containing layer particles:

[0086] Grind nifedipine, polyoxyethylene (molecular weight: 300,000) and sodium lauryl sulfate into fine powder, pass through a 100-mesh sieve, mix well, make a soft material with 10% povidone ethanol solution, pass through a 40-mesh sieve Granules, dried at 45°C for 12 hours, added with 1% magnesium stearate and 0.5% silicon dioxide, and mixed evenly to obtain drug-containing layer granu...

Embodiment 3

[0096] (1) Drug-containing layer

[0097]

[0098] Prepare soft materials with 10% PVPK30 ethanol solution

[0099] (2) booster layer

[0100] Polyoxyethylene (molecular weight 5 million) 60g

[0101] HPMC (K4M) 12.4g

[0103] Iron Oxide Red 1.72g

[0104] Prepare soft materials with 10% PVPK30 ethanol solution

[0105] (3) Prescription of coating solution

[0106] Cellulose acetate (398-10NF) 60g

[0107] PEG 4000 6g

[0108] DEP10%

[0109] Proper amount of acetone

[0110] Preparation:

[0111] 1. Preparation of drug-containing layer particles:

[0112] Grind nifedipine, polyoxyethylene (molecular weight: 200,000) and poloxamer 188 into fine powder, pass through a 100-mesh sieve, mix well, make soft material with 10% povidone ethanol solution, pass through a 40-mesh sieve to granulate , dried at 45°C for 12 hours, added 1% magnesium stearate and 0.5% silicon dioxide, and mixed evenly to obtain drug-containing layer granules. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com