Method for extracting leaf protein from alfafa hay

A technology of alfalfa and leaf protein is applied in the direction of animal feed, additional food elements, animal feed, etc. It can solve the problems of idle production equipment and waste, and achieve the effects of saving investment, low cost and reducing extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

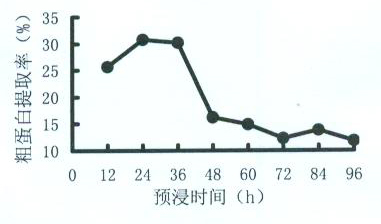

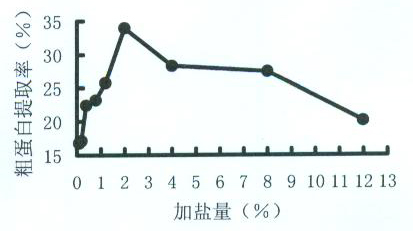

[0018] (1) Crush air-dried or dried alfalfa with a moisture content of less than 15%, pass through a 60-mesh sieve, weigh 10g of alfalfa powder, add 2% of the weight of alfalfa powder, that is, 0.2g, and then add 10 times the weight Soak in grass powder water for 12h.

[0019] (2) Beat the pulp for 5 minutes, filter or centrifuge with a 120-mesh filter cloth to obtain green juice.

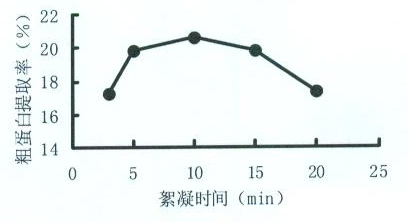

[0020] (3) Adjust the pH value of the green juice to 3 with 0.5mol / L sodium hydroxide and 0.5mol / L hydrochloric acid, quickly put it into a boiling water bath and heat it to 60°C, then transfer it to a constant temperature water bath at the same temperature for flocculation for 10 minutes.

[0021] (4) Quickly cool to room temperature with cold water, let it stand for 1 hour, filter or centrifuge to obtain leaf protein paste, and dry it in an oven at 60°C-70°C to obtain the finished leaf protein, which is stored in a sealed container. The yield of leaf protein can reach 8.87%, and the purity can r...

Embodiment 2

[0024] (1) Crush air-dried or dried alfalfa with a moisture content of less than 15%, pass through a 60-mesh sieve, weigh 10g of alfalfa powder, add 1% of the weight of alfalfa powder, that is, 0.1g, and then add 20 times the weight Soak in grass powder water for 24 hours.

[0025] (2) Beat the pulp for 5 minutes, filter or centrifuge with a 120-mesh filter cloth to obtain green juice.

[0026] (3) Adjust the pH value of the green juice to 3.5 with 0.5moL / L sodium hydroxide and 0.5moL / L hydrochloric acid, quickly put it in a boiling water bath and heat it to 60°C, then transfer it to a constant temperature water bath at the same temperature for flocculation for 10 minutes.

[0027] (4) Quickly cool to room temperature with cold water, let it stand for 1 hour, filter or centrifuge to obtain leaf protein paste, and dry it in an oven at 60°C-70°C to obtain the finished leaf protein, which is stored in a sealed container. The highest yield of leaf protein can reach 11.48%, and th...

Embodiment 3

[0030] (1) Crush air-dried or dried alfalfa with a moisture content of less than 15%, pass through a 60-mesh sieve, weigh 10g of alfalfa powder, add 1% of the weight of alfalfa powder, that is, 0.1g, and then add 30 times the weight Soak in grass powder water for 24 hours.

[0031] (2) Beat the pulp for 5 minutes, filter or centrifuge with a 120-mesh filter cloth to obtain green juice.

[0032] (3) Adjust the pH value of the green juice to 3 with 0.5moL / L sodium hydroxide and 0.5moL / L hydrochloric acid, quickly put it in a boiling water bath and heat it to 60°C, then transfer it to a constant temperature water bath at the same temperature for flocculation for 15 minutes.

[0033] (4) Quickly cool to room temperature with cold water, let it stand for 1 hour, filter or centrifuge to obtain leaf protein paste, and dry it in an oven at 60°C-70°C to obtain the finished leaf protein, which is stored in a sealed container. The highest yield of leaf protein can reach 11.52%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com