Carbon fiber expanding and heating cable for oil extraction

A carbon fiber heating wire, expansion and heating technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of affecting the heat transfer effect of heating cables, reducing the insulation performance of heating cables, and aging of heating cable insulation, so as to improve the electrothermal conversion efficiency , light weight, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

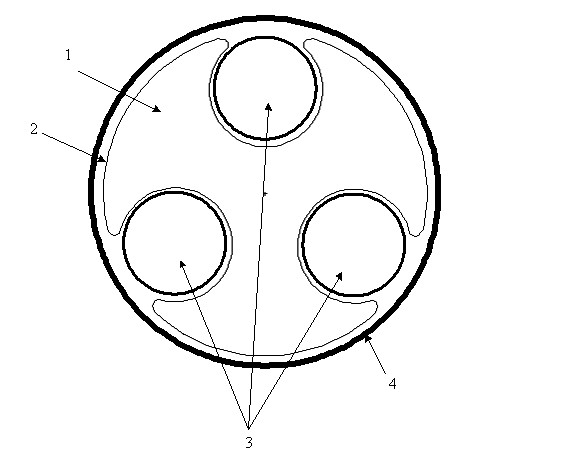

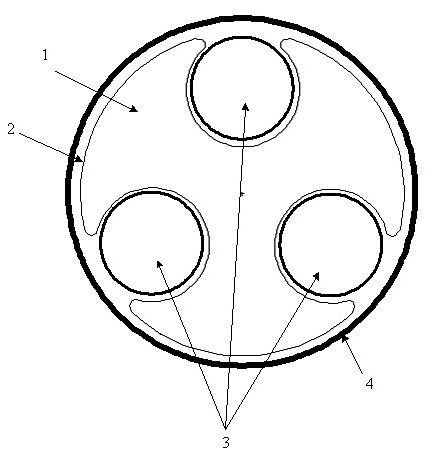

[0020] like figure 1 As shown, the carbon fiber expansion heating cable for oil production of the present invention has the following structure: the core is made of a sealing layer 2 made of a silica gel-based composite material with thermal expansion, heat conduction, insulation, and high temperature resistance properties, and an isolation layer arranged inside the sealing layer 2 The expansion cavity 1 is composed of an expansion filler in the isolation expansion cavity 1; carbon fiber heating wires 3 are inlaid on the sealing layer 2, and the carbon fiber heating wires 3 are evenly distributed along the outer circumference of the sealing layer 2; the outer surface of the sealing layer 2 is wrapped with a protective layer 4. The protective layer 4 is also made of silica gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com