Hybrid fiber pultruded composite material, and preparation method and molding device thereof

A composite material and hybrid fiber technology, which is used in cable/conductor manufacturing, cables, insulated conductors, etc., can solve the problems of small sag at high temperature, low coaxiality and roundness, and low glass transition temperature. Corrosion performance, improved coaxiality, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

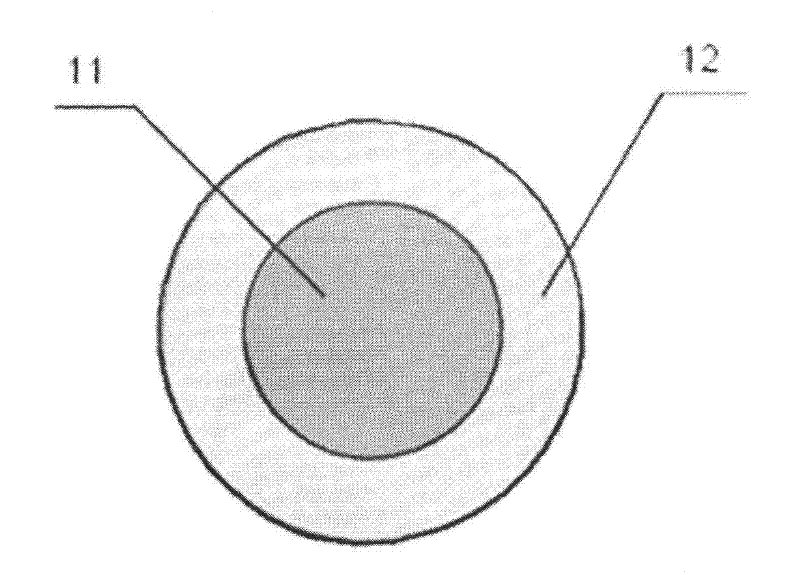

[0022] Such as figure 1 As shown, the carbon fiber core layer 11 of the hybrid fiber pultrusion composite material that realizes the coaxial structure uses 12K Toray T700 carbon fiber in Japan, and the glass fiber shell layer 12 uses E glass fiber from Owens Corning SE8400LS, and the inner carbon fiber core layer 11 has a diameter of 7 mm, the overall diameter of the pultruded composite is 9.5 mm, and the outer fiberglass shell 12 has a thickness of 2.5 mm.

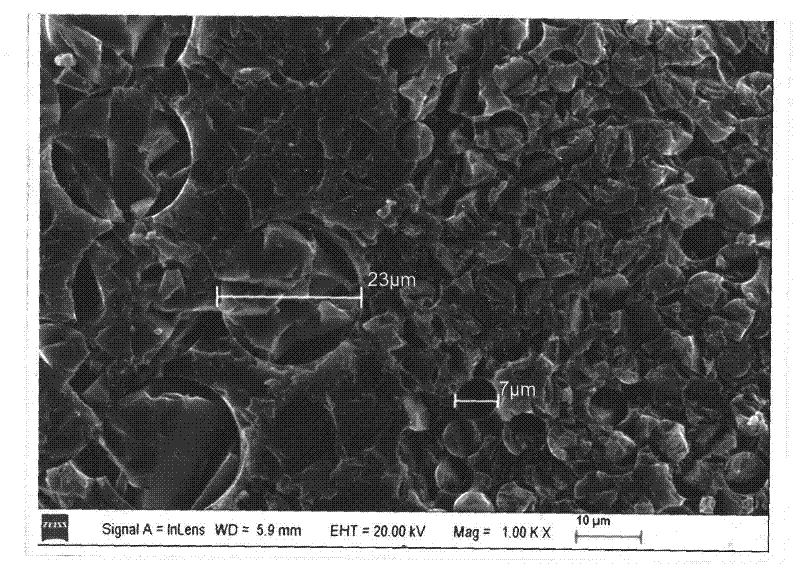

[0023] Such as figure 2 As shown, the diameter of the carbon fiber (right side) is 7 μm, and the diameter of the glass fiber (left side) is 23 μm. The interface between the carbon fiber core layer and the glass fiber shell layer in the pultruded composite material is well bonded. The fiber volume fraction of the core and sheath is about 70%.

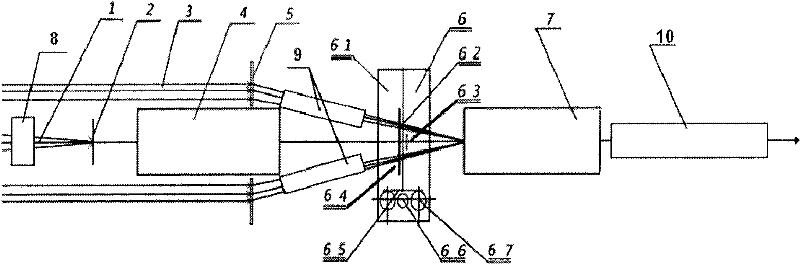

[0024] Such as image 3 As shown, the core layer carbon fiber 1 is pulled out from the creel with a certain tension, passes through a dryer, and removes surface moisture under t...

Embodiment 2

[0027] The carbon fiber core layer 11 of the hybrid fiber pultrusion composite material that realizes the coaxial structure adopts 6K T300 carbon fiber of PetroChina Jihua Company, and the glass fiber shell layer 12 adopts 8K E glass fiber of Saint-Gobain Company in France, and the diameter of the inner carbon fiber core layer 11 is 6 mm, the overall diameter of the pultruded composite material is 8 mm, and the thickness of the outer glass fiber shell 12 is 2 mm. The fiber volume fraction of the core and sheath is about 65%.

[0028] Such as image 3 As shown, the core layer carbon fiber 1 is pulled out from the creel with a certain tension, passes through a dryer, and removes surface moisture under the condition of 60-100°C. Next, the carbon fiber of the core layer is divided into 20 bundles of fibers by a yarn splitter and enters the front molding tank 8, and the preheating temperature of the front molding tank is 70°C. The resin in the glue tank of the front mold is a med...

Embodiment 3

[0031] The carbon fiber core layer 11 of the mixed fiber pultrusion composite material that realizes the coaxial structure adopts 6K T300 carbon fiber from Toray Corporation of Japan, and the glass fiber shell layer 12 adopts 8K E glass fiber from Owens Corning Company, and the diameter of the inner carbon fiber core layer is The pultruded composite has an overall diameter of 12 mm and an outer fiberglass shell of 4 mm in thickness. The fiber volume fraction of the core and sheath is about 70%.

[0032] Such as image 3 As shown, the core layer carbon fiber 1 is pulled out from the creel with a certain tension, passes through the dryer, and removes the moisture on the surface under the condition of 80-100°C. Next, the carbon fiber of the core layer is divided into 20 bundles of fibers by a yarn splitter and enters the front molding tank 8, and the preheating temperature of the front molding tank is 70°C. The resin in the plastic tank of the front mold is a medium-high temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com