Charge testing method in plasma environment and testing system

A test system and plasma technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve problems such as non-reusable, unable to fully meet test requirements, plasma damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

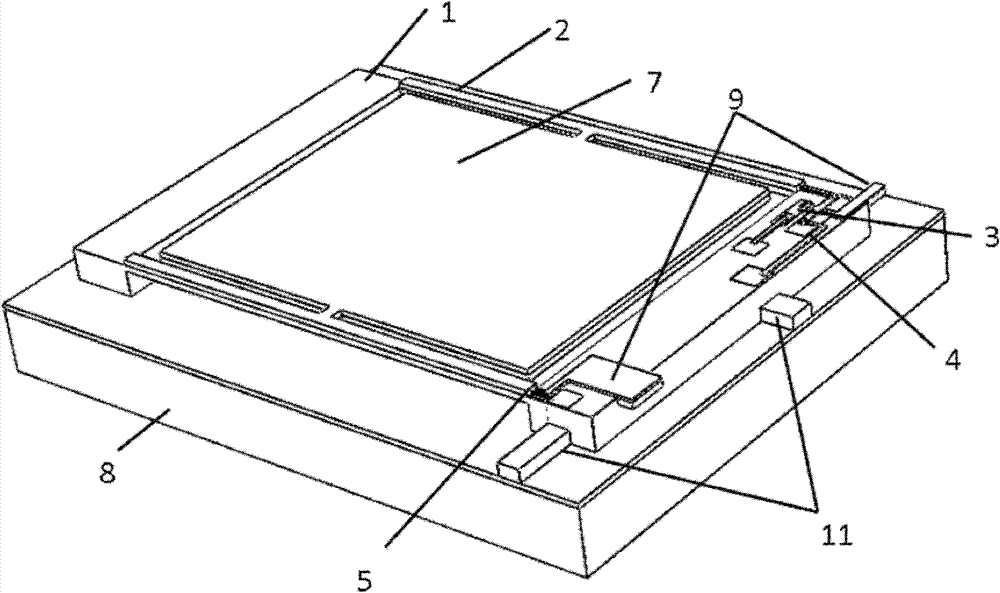

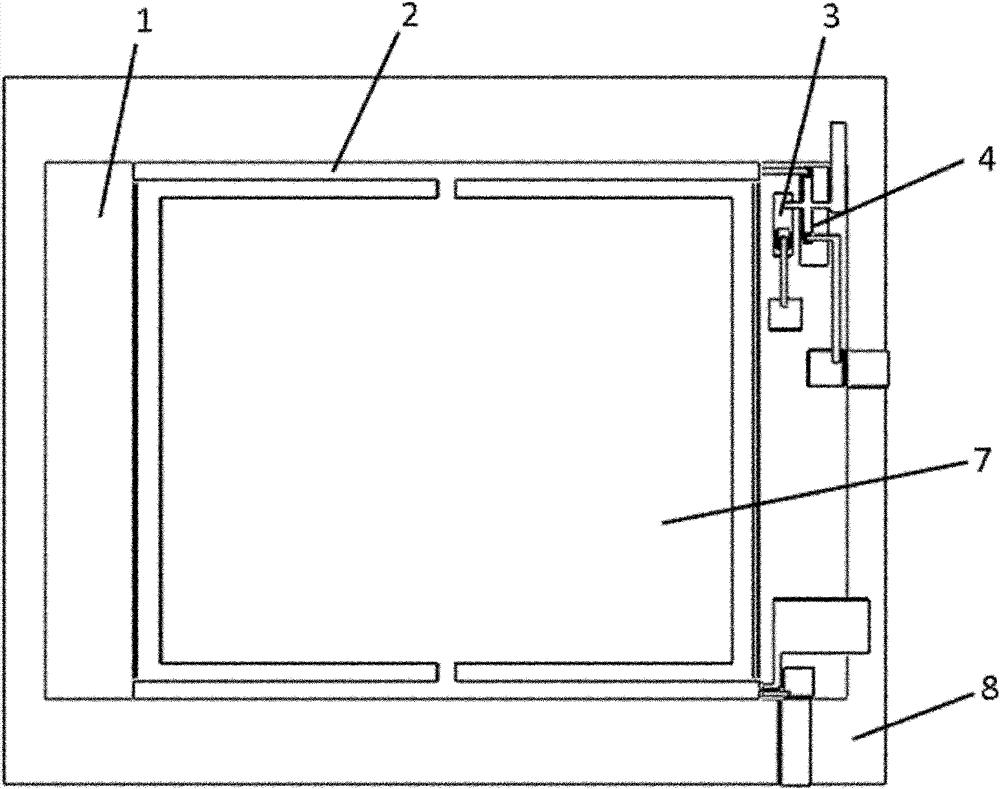

[0102] A charge detection chip that can be used to monitor plasma processing technology is prepared by monolithic integration of microelectromechanical system (MEMS) technology and IC (CMOS) technology. Such as figure 2 As shown in Figure 3, the test unit of the chip is located on the substrate 8, and consists of five main functional components: the lower plate 6, the bi-material beam 2, the piezoresistor 5, the MOS switch 4, and the protection diode 3, among which:

[0103] The double-material beam 2 is composed of a structural layer on the lower layer and a metal layer on the upper layer, and the shapes of the structural layer and the metal layer are completely coincident. The top view of the bimaterial beam 2 is a centrosymmetric figure, such as Figure 4 shown. In order to accumulate enough charges on a limited chip area, the middle of the bimaterial beam 2 is designed as a large-area rectangular flat plate, and its upper layer is the metal pole plate 7 . The central s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com