Method for promoting decomposition of straw lignocellulose

A technology of lignocellulose and straw, applied in the biological field, can solve the problems of high cost, insufficient utilization of straw resources, poor effect, etc., and achieve the effect of increasing the concentration of reducing sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

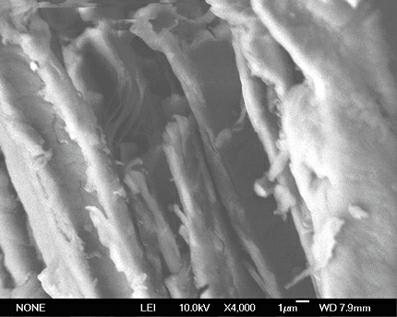

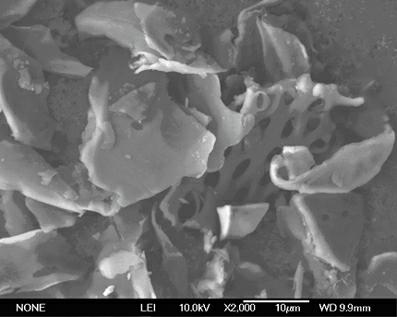

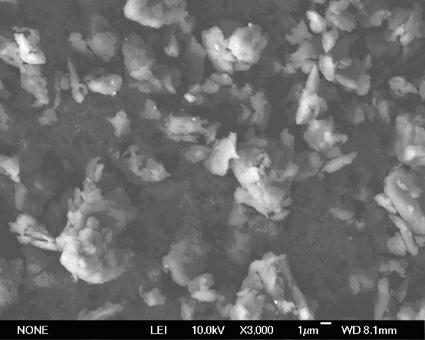

[0019] A method to promote the decomposition of straw lignocellulose: After cutting the sorghum stalks, place them in an oven at 55°C for 7 hours, first use a crusher (manufactured by Tianjin Test Instrument Co., Ltd., model FY130) to coarsely crush to 160 mesh, and then Use a hanging nano ball mill (produced by Qinhuangdao Taiji Nano Co., Ltd., model MY-SQ-B) to superfinely pulverize for 4 hours, and the obtained straw particle size range is 330~420nm.

Embodiment 2

[0021] A method to promote the decomposition of straw lignocellulose: After cutting the straw into pieces, place it in an oven at 62°C for 5 hours, first crush it to 200 mesh with a crusher (manufactured by Tianjin Test Instrument Co., Ltd., model FY130), and then use it. Hanging type nano ball mill (produced by Qinhuangdao Taiji Nano Co., Ltd., model MY-SQ-B) can be superfinely pulverized for 6 hours, and the obtained straw particle size range is 330~420nm.

[0022] The sorghum stalks obtained in the above examples have a particle size range of nanometers (330~420nm). When using them for enzymatic hydrolysis, the concentration of reducing sugars produced is detailed in Figure 5 . Enzymatic hydrolysis reaction conditions: add 120mg of cellulase (Trichoderma viride, enzyme activity 3×10 per 100mL, pH 4.8 citric acid-sodium citrate buffer) 4 U·g -1 , Provided by Zhengzhou Boxing Biological Technology Co., Ltd.), then add 2g of the sorghum straw particles obtained in Example 2 to ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com