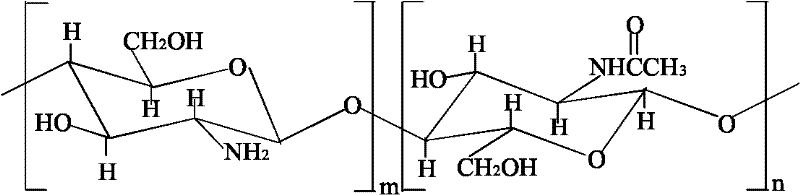

Absorbent material for selectively absorbing As<+5> ions and preparation method thereof

An ion adsorption and selective technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of expensive, unfavorable scale production, groundwater purification and preparation difficulties, and achieve accurate adsorption, Excellent long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh chitosan 0.05mol, add single-capped polyethylene glycol-400 with acrylic acid or methacrylic acid single-capped polyethylene glycol-400 macromonomer: chitosan=1: 1~5 (mol ratio) Macromonomer: Add double-capped polyethylene glycol-400 macromer with acrylic acid or methacrylic acid double-capped macromonomer: single-capped polyethylene glycol-400 macromonomer=1.5:1 (mol ratio) Alcohol-400 macromonomer was used as a crosslinker. Disperse 0.05mol of chitosan in 50% ethanol aqueous solution, the amount of the above ethanol aqueous solution is the required amount to make 0.05mol chitosan form a solution with a percentage concentration of 2.5% to 3%. . Then add the photoinitiator of single end-capped polyethylene glycol-400 macromonomer, double end-capped polyethylene glycol-400 macromonomer and the total mass of the above two reactive monomers of 1 to 5% respectively in the above dispersion liquid 1173, stir well. Regulate the acidity of the solution with acrylic aci...

Embodiment 2

[0025] Weigh chitosan 0.05mol, add single-capped polyethylene glycol-1000 with chitosan:acrylic acid or methacrylic acid single-capped polyethylene glycol-1000 macromonomer=1:1~5 (mol ratio) Macromonomer: Add double-capped polyethylene glycol with acrylic acid or methacrylic acid double-capped polyethylene glycol-1000 macromonomer: single-capped polyethylene glycol-1000 macromonomer=1.5:1 (mol ratio) Alcohol-1000 macromonomer was used as a crosslinker. Disperse 0.05mol of chitosan in 50% ethanol aqueous solution, the amount of the above ethanol aqueous solution is the required amount to make 0.05mol chitosan form a solution with a percentage concentration of 2.5% to 3%. . Then add the photoinitiator of single-end capped polyethylene glycol-1000 macromonomer, double-capped polyethylene glycol-1000 macromonomer and the total mass of the above two reactive monomers to 1-5% respectively in the above dispersion liquid 1173, stir well. Adjust the acidity of the solution with acry...

Embodiment 3

[0028] Weigh chitosan 0.05mol, add single-capped polyethylene glycol-400 with acrylic acid or methacrylic acid single-capped polyethylene glycol-400 macromonomer: chitosan=1: 1~5 (mol ratio) Macromonomer: Add double-capped polyethylene glycol-1000 macromonomer with acrylic acid or methacrylic acid double-capped polyethylene glycol-400 macromonomer=1.5:1 (mol ratio) Alcohol-400 macromonomer was used as a crosslinker. Disperse 0.05mol of chitosan in 50% ethanol aqueous solution, the amount of the above ethanol aqueous solution is the required amount to make 0.05mol chitosan form a solution with a percentage concentration of 2.5% to 3%. . Then add the photoinitiator of single-capped polyethylene glycol-400 macromonomer, double-capped polyethylene glycol-1000 macromonomer and the total mass of the above two reactive monomers to 1-5% respectively in the above dispersion liquid 1173, stir well. Regulate the acidity of the solution with acrylic acid or methacrylic acid to dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com