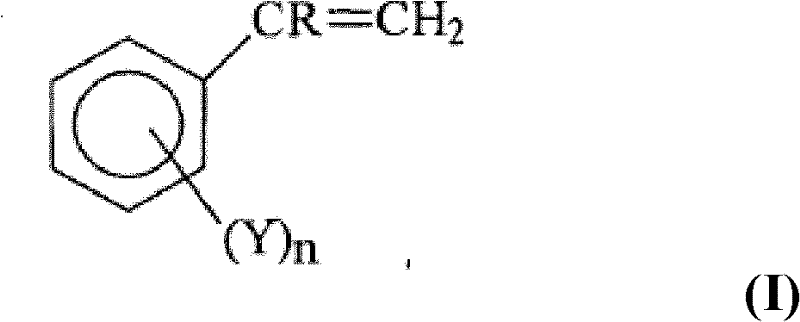

Process for the synthesis of functionalized poly(1,3-alkadienes) and use thereof in the preparation of high impact vinyl aromatic polymers

A vinyl aromatic, functionalized technology for the preparation of styrene polymers grafted on functionalized polybutadiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Embodiment 1 (contrast)

[0102] In a nitrogen stream, the following products were successively introduced into a 100-liter water-free reactor, which was equipped with a stirrer and a heating jacket, and heat transfer oil at a temperature of 50° C. was circulated in the jacket: 50 kg of anhydrous Aqueous cyclohexane, 6.5 kg of anhydrous butadiene without inhibitors and alkynes and 5 g THF. When the reaction mixture reached a temperature of 40° C., 2.6 g of a 15% by weight solution of butyllithium dissolved in cyclohexane was added. When the conversion was complete, a 2.77 g portion of trimethylchlorosilane was fed into the reactor at a temperature of 105°C to achieve complete termination of the chain ends.

[0103] The reagent mixture is then released into a pressurized container where the 565 and 168, added in amounts such that their contents in the elastomer were equal to 0.1 and 0.4%, respectively.

[0104] The polymer is then separated from the solvent by stri...

Embodiment 2

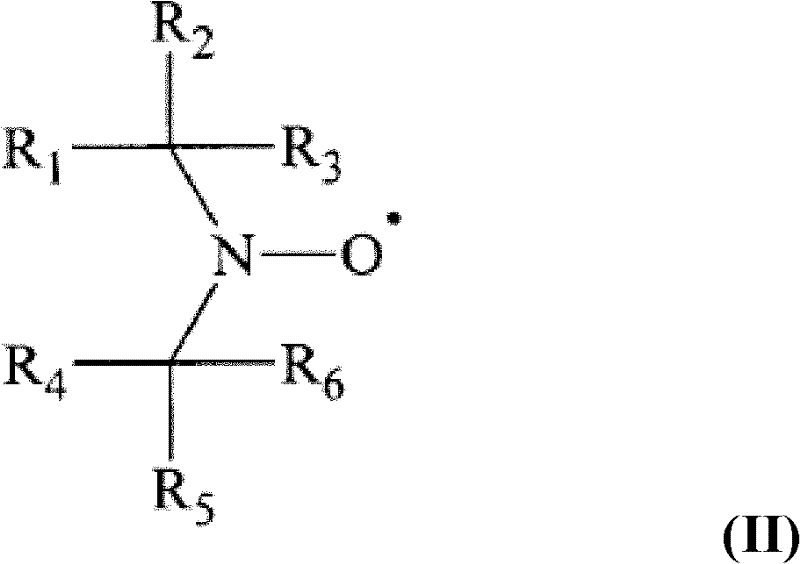

[0110] In a nitrogen stream, the following products were successively introduced into a 100-liter water-free reactor, which was equipped with a stirrer and a heating jacket, and heat transfer oil at a temperature of 50° C. was circulated in the jacket: 50 kg of anhydrous Aqueous cyclohexane, 6.5 kg of anhydrous butadiene without inhibitors and alkynes and 5 g THF. When the reaction mixture reached a temperature of 40° C., 2.16 g of a 15% by weight solution of butyllithium dissolved in cyclohexane was added. When the conversion is complete, a portion of 0.83 g of a 5% solution of butyllithium dissolved in cyclohexane is fed into the reactor at a temperature of 105° C., and after waiting 5′, a second portion of 6.6 g 5% solution of butyllithium dissolved in cyclohexane. Immediately after the second addition of butyllithium, 20 g of octyl bromide in 20% cyclohexane was added, followed immediately by 25.6 g of 1,1,3,3-tetraethylisoindolin-2-yl Oxygen (TEDIO).

[0111] The reage...

Embodiment 3

[0116] Embodiment 3 (contrast)

[0117] In a nitrogen stream, the following products were successively introduced into a 100-liter water-free reactor, which was equipped with a stirrer and a heating jacket, and heat transfer oil at a temperature of 50° C. was circulated in the jacket: 50 kg of anhydrous Aqueous cyclohexane, 6.5 kg of anhydrous butadiene without inhibitors and alkynes and 5 g THF. When the reaction mixture reached a temperature of 40° C., 1.5 g of a 15% by weight solution of butyllithium dissolved in cyclohexane was added. When the conversion was complete, a 2 g portion of trimethylchlorosilane was fed into the reactor at a temperature of 102°C to achieve complete termination of the chain ends.

[0118] The reagent mixture is then released into a pressurized container where the 565 and 168, added in amounts such that their contents in the elastomer were equal to 0.1 and 0.4%, respectively.

[0119] The polymer is then separated from the solvent by strippi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com