Novel water pipe structure for high voltage direct current converter valve

A high-voltage direct current, converter valve technology, applied in output power conversion devices, electrical components, cooling/ventilation/heating transformation and other directions, can solve problems such as excessive flow of water joints, small resistance of water cooling system, large temperature difference, etc. , to achieve the effect of reducing the possibility of corrosion and leakage, reducing water flow and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

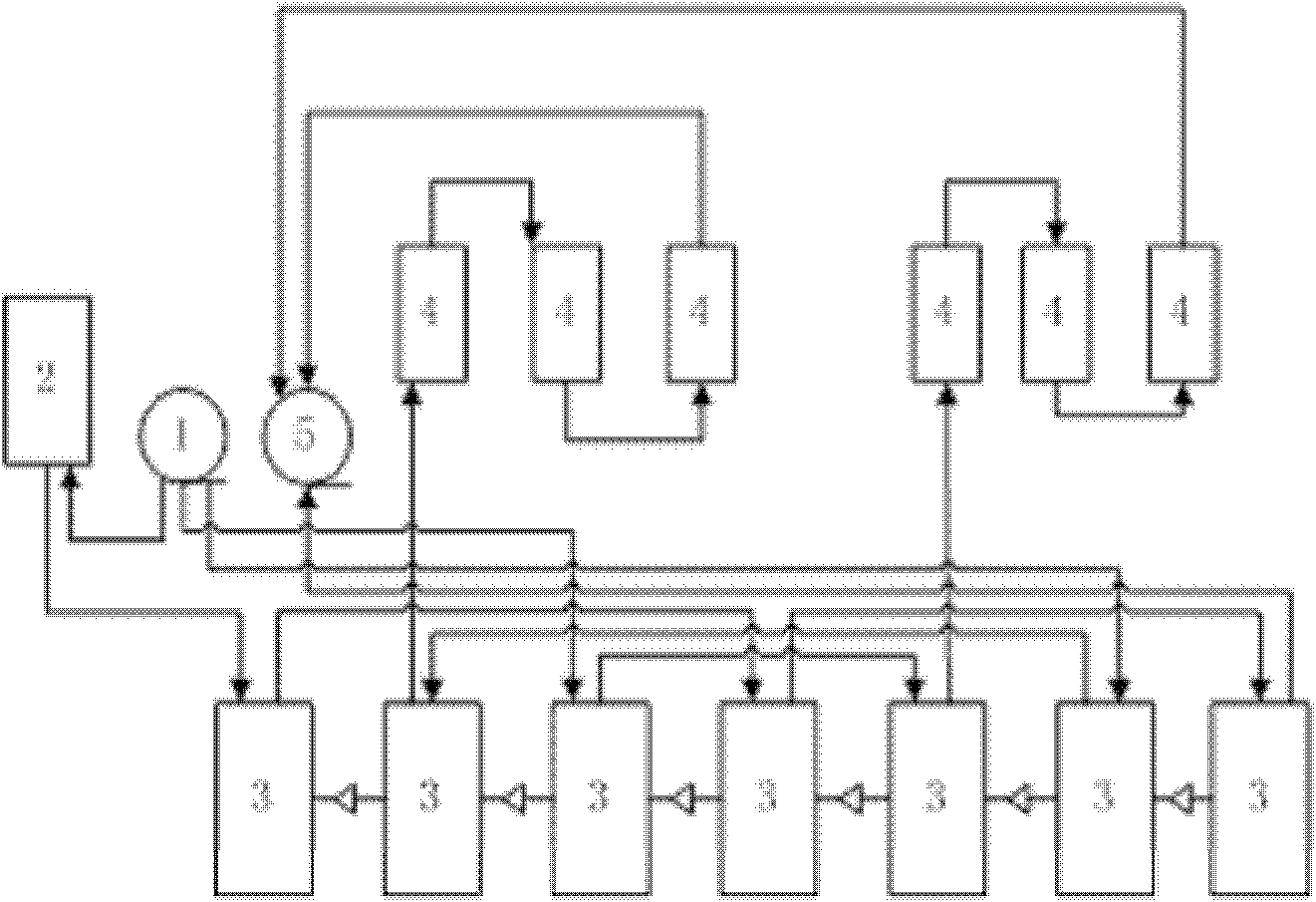

[0020] Such as figure 1 As shown, a hydraulic impact device in this example includes a water inlet 1, a saturated reactor 2, a crystal valve tube radiator 3, a damping resistor 4 and a water outlet 5, and the water pipe structure includes at least two independent cooling branches Composed in parallel, the cooling branch in this scheme includes three independent cooling branches, the first branch, the second branch and the third branch, and each independent cooling branch is connected in series, and the three independent The cooling branch uses a water inlet 1 and a water outlet 5 in common. The first branch includes the water inlet 1, the saturated reactor 2, three crystal valve tube radiators 3 and the water outlet 5, and the second branch includes the water inlet 1, Two crystal valve tube radiators 3 , three damping resistors 4 and a water outlet 5 , and the third branch includes a water inlet 1 , two crystal valve tube radiators 3 , three damping resistors 4 and a water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com