Method for preparing cobalt-zinc ferrite/polypyrrole nano composite material

A technology of pyrrole nanometer and composite material, which is applied in the directions of cobalt oxide/cobalt hydroxide, iron oxide/iron hydroxide, etc., to achieve the effects of simple process operation, broad application prospect and strong magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

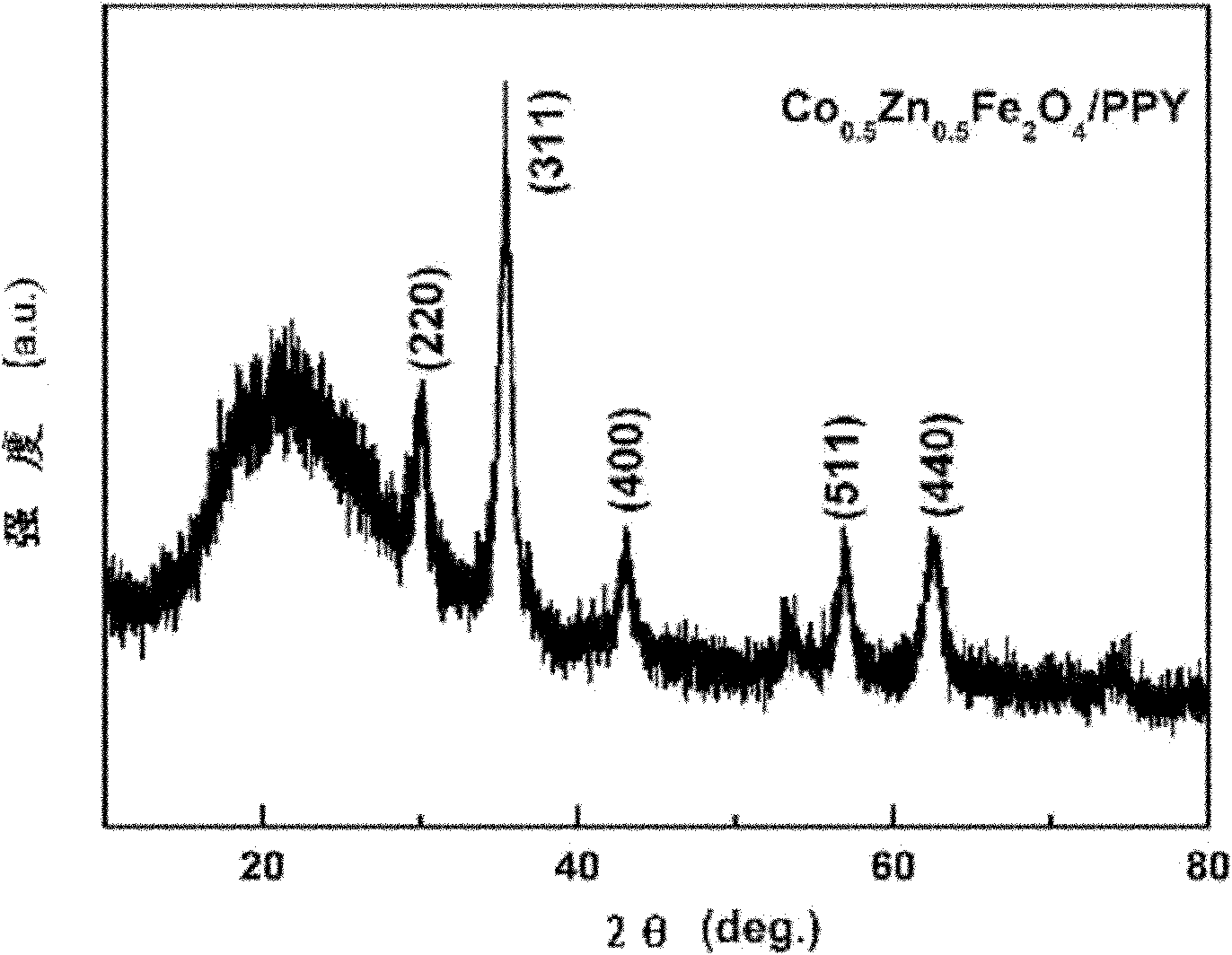

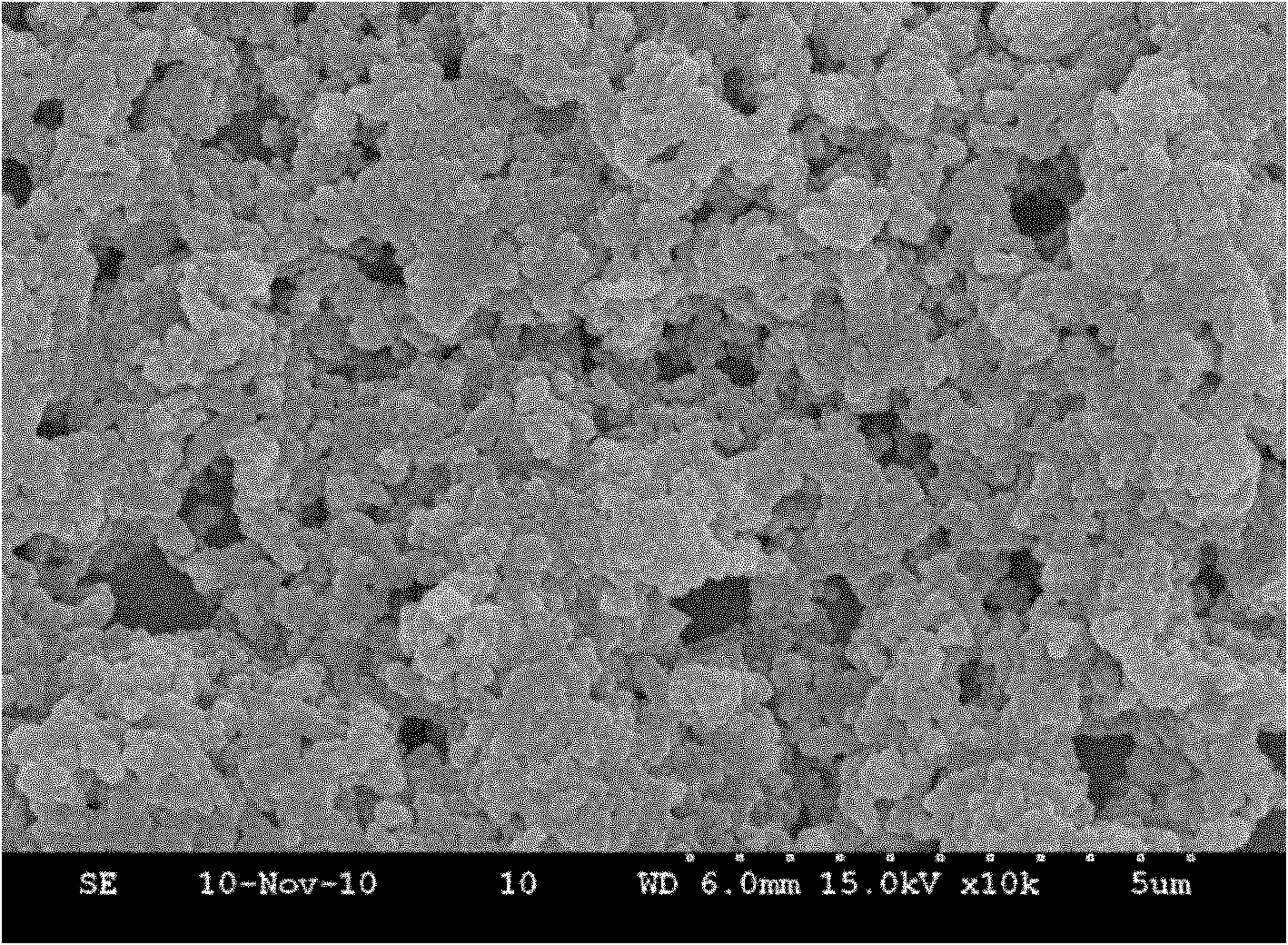

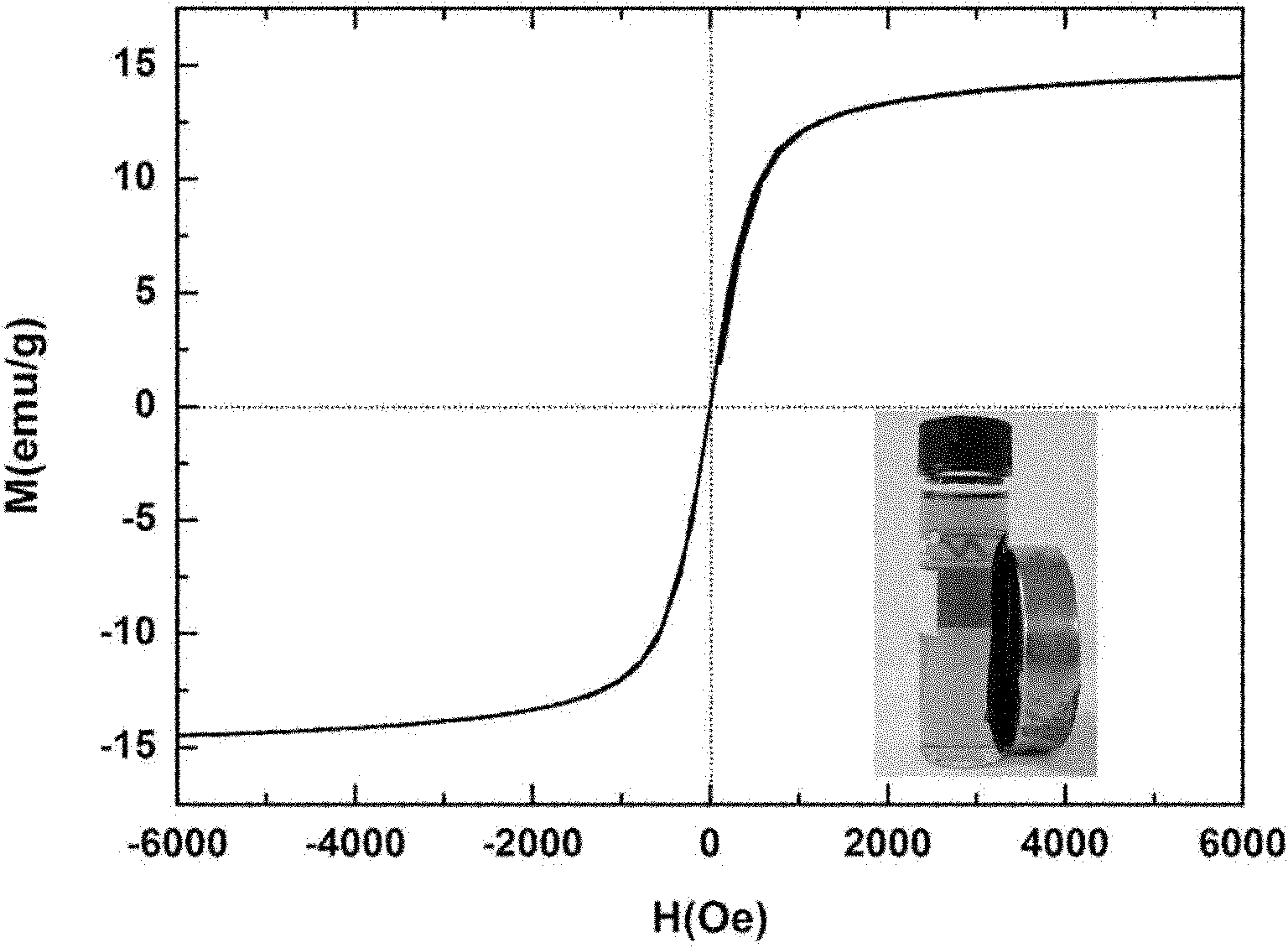

[0034] (1) Weigh 1.3518g of ferric chloride hexahydrate, 0.3765g of cobalt nitrate hexahydrate, and 0.3722g of zinc nitrate hexahydrate into a 200ml beaker, then add 60ml of ethylene glycol, and stir mechanically at room temperature for 35min. Then add 1.6415g of anhydrous sodium acetate and 1.5ml of polyethylene glycol 200, and ultrasonically disperse for 30 minutes. After it is completely dissolved, pour the above solution into the reaction kettle, raise the temperature to 180°C, and react for 30 hours. After the reaction, the product was collected with a magnet, washed with deionized water and absolute ethanol, and then dried in vacuum at 70°C for 24 hours to obtain Co 0.5 Zn 0.5 Fe 2 o 4 Nano microsphere powder;

[0035] (2) Dissolve 0.7018g sodium dodecylbenzenesulfonate in 200ml deionized water to form an emulsion, add 0.2014g of the above Co 0.5 Zn 0.5 Fe 2 o 4 Nano microsphere powder, stir evenly, and ultrasonically disperse, so that the surfactant and Co 0.5 Z...

Embodiment 2

[0039] (1) Weigh 1.3512g of ferric chloride hexahydrate, 0.5819g of cobalt nitrate hexahydrate, and 0.1488g of zinc nitrate hexahydrate into a 200ml beaker, then add 55ml of ethylene glycol, and stir mechanically at room temperature for 45min. Then add 4.0110g of anhydrous sodium acetate and 1ml of polyethylene glycol 400, and ultrasonicate the mixture for 40 minutes. After it is completely dissolved, pour the above solution into the reaction kettle, raise the temperature to 210°C, and react for 18 hours. At the end of the reaction, the product was collected with a magnet, and the product was washed with deionized water and absolute ethanol, and then the product was vacuum-dried at 80 ° C for 20 h to obtain Co 0.8 Zn 0.2 Fe 2 o 4 Nano microsphere powder;

[0040] (2) Dissolve 0.6054g sodium dodecylbenzenesulfonate in 200ml deionized water to form an emulsion, add 0.2018g of the above Co 0.8 Zn 0.2 Fe 2 o 4 Nano microsphere powder, stir evenly, and ultrasonically dispers...

Embodiment 3

[0044] (1) Weigh 1.3523g of ferric chloride hexahydrate, 0.4134g of cobalt nitrate hexahydrate, and 0.2978g of zinc nitrate hexahydrate into a 200ml beaker, then add 50ml of ethylene glycol, and stir mechanically at room temperature for 40min. Then add 6.017g of anhydrous sodium acetate and 1ml of polyethylene glycol 800, and ultrasonicate the mixture for 50min. After it is completely dissolved, pour the above solution into the reaction kettle, raise the temperature to 190°C, and react for 26h. At the end of the reaction, the product was collected with a magnet, and the product was washed with deionized water and absolute ethanol, and then the product was vacuum-dried at 90°C for 18h to obtain Co 0.6 Zn 0.4 Fe 2 o 4 Nano microsphere powder;

[0045] (2) Dissolve 0.5025g sodium dodecylbenzenesulfonate in 200ml deionized water to form an emulsion, add 0.2010g of the above Co 0.6 Zn 0.4 Fe 2 o 4 Nano microsphere powder, stir evenly, and ultrasonically disperse, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com