Method for detecting release situation of nicotine in buccal tobacco products

A tobacco product and detection port technology, applied in the field of tobacco, can solve the problems of inability to detect the release rate of nicotine, instability of the supporting liquid film device, and large fluctuation of measurement results, etc., and achieve the advantages of easy promotion, short detection cycle and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

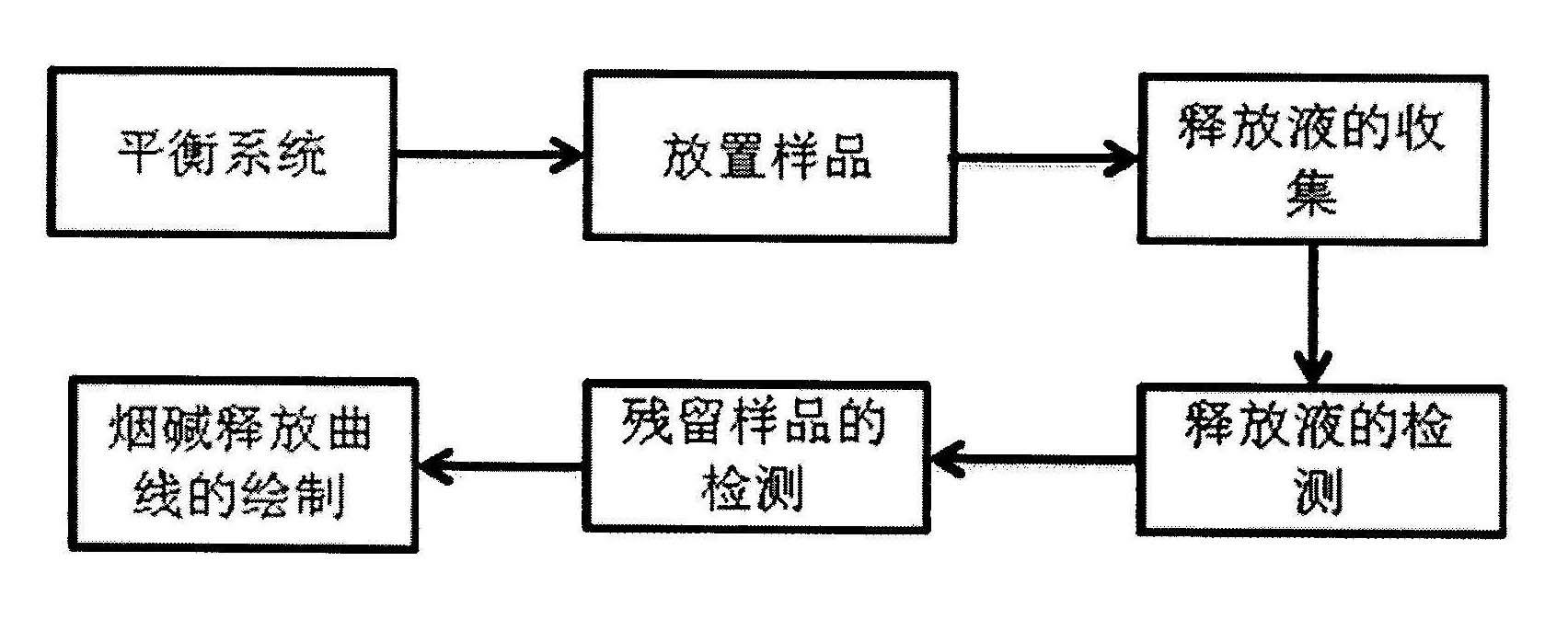

Method used

Image

Examples

Embodiment 1

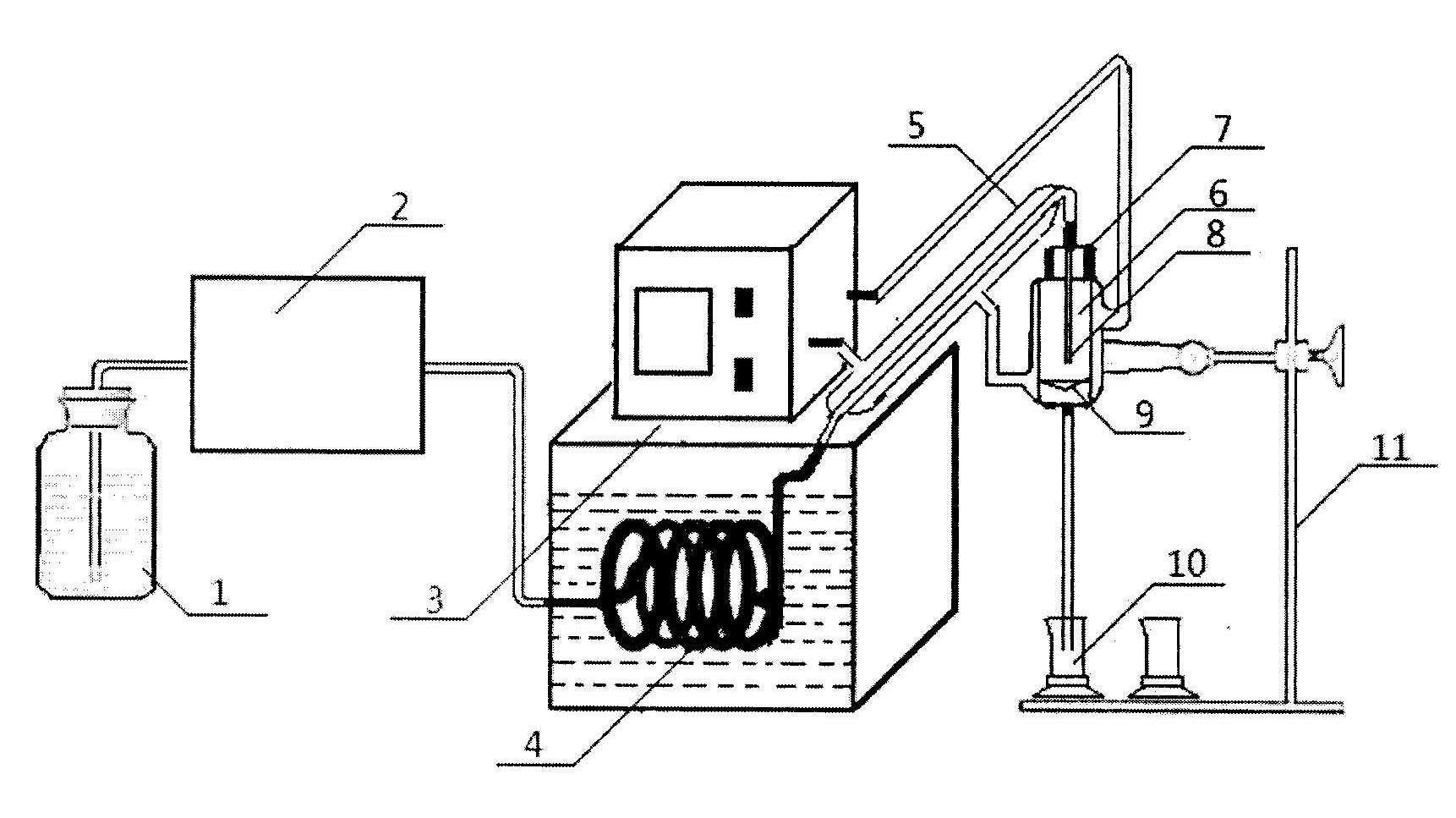

[0035] The flow rate was 0.2 mL / min, the temperature was 37°C, and the pH of the artificial saliva was 6.7; the detection of nicotine in the released liquid was performed by high-performance liquid chromatography, and the chromatographic parameters were as follows: the chromatographic column was Waters XTerra RP C18 reversed-phase chromatographic column, The mobile phase is methanol and 20 mmol of phosphate buffer solution (triethylamine is added in the mobile phase, and the content is 0.2%, the purpose is that triethylamine can effectively improve the tailing of the nicotine chromatographic peak, the retention time becomes larger, and the phosphoric acid pH of salt buffer solution = 6.0), the ratio is 23:77, the flow rate is 1 mL / min, and the column temperature is 35 °C.

[0036] Add artificial saliva with a pH of 6.7 into the solvent storage bottle, turn on the constant temperature tank and constant flow pump, set the flow rate to 0.2 mL / min, and after the system stabilizes t...

Embodiment 2

[0038] The flow rate was 0.4mL / min, the temperature was 37°C, and the pH of the artificial saliva was 6.4; the detection of nicotine in the release liquid was performed by high performance liquid chromatography, and the chromatographic parameters were the same as in Example 1.

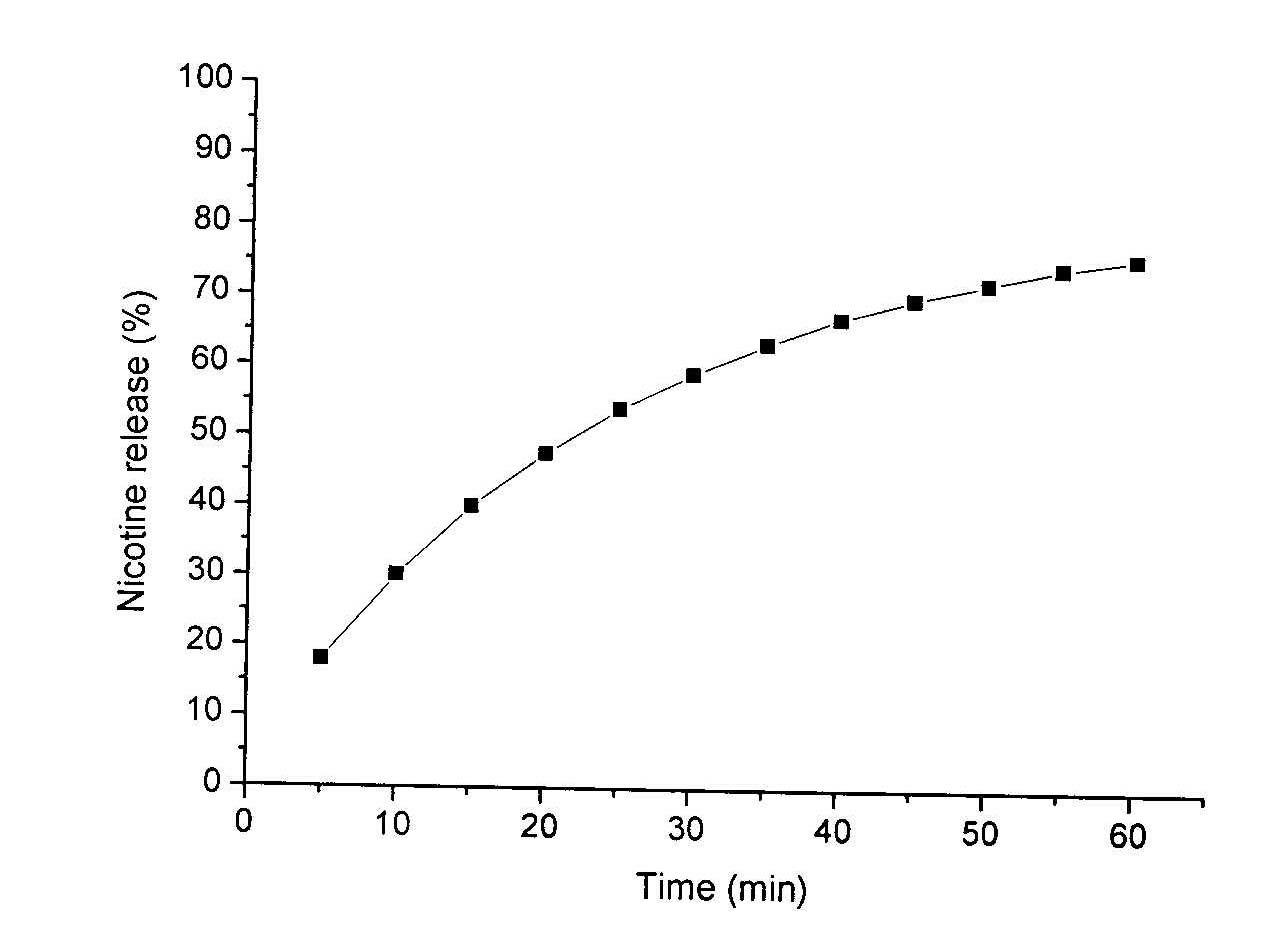

[0039] Add the artificial saliva with a pH of 6.4 into the solvent storage bottle, turn on the constant temperature tank and constant flow pump, and set the flow rate to 0.4 mL / min. After the system stabilizes to 37 °C, open the glass ground plug and place the sample flat Cover the stand with a ground stopper, and at the same time, collect once every 5 minutes for a total of 60 minutes. After the release solution is collected, take out the remaining sample after release and put it into a 50 mL Erlenmeyer flask, add 20 mL of ethanol and A mixed solution of 5% NaOH solution (9:1), ultrasonically extracted for 30 min. After the nicotine release solution and the residual sample extraction solution pass thr...

Embodiment 3

[0041] The flow rate was 1 mL / min, the temperature was 37 °C, and the pH of the artificial saliva was 7.0; the detection of nicotine in its release liquid was performed by high-performance liquid chromatography, and the chromatographic parameters were the same as in Example 1

[0042] Add artificial saliva with a pH of 7.0 to the solvent storage bottle, turn on the constant temperature tank and constant flow pump, set the flow rate to 1 mL / min, and after the system stabilizes to 37 °C, open the glass ground plug and place the sample flat On the sample holder, cover the ground plug, and time it at the same time, respectively at 1min, 2min, 3min, 4min, 5min, 6min, 7min, 8min, 9min, 10min, 12min, 14min, 16min, 18min, 20min, 24min, 28min, At 32 minutes, the released liquid was collected into corresponding collection bottles. After the release solution was collected, the residual sample after release was taken out and placed in a 50 mL Erlenmeyer flask, and 20 mL of a mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com