Flue gas flow velocity measuring device and method

A flue gas flow velocity and measuring instrument technology, which is applied in fluid velocity measurement, average velocity measurement, velocity/acceleration/shock measurement, etc., can solve the problems of unable to measure light flicker signal, no future, smoke and dust concentration cannot be measured, etc., to achieve measurement The effect of high precision and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

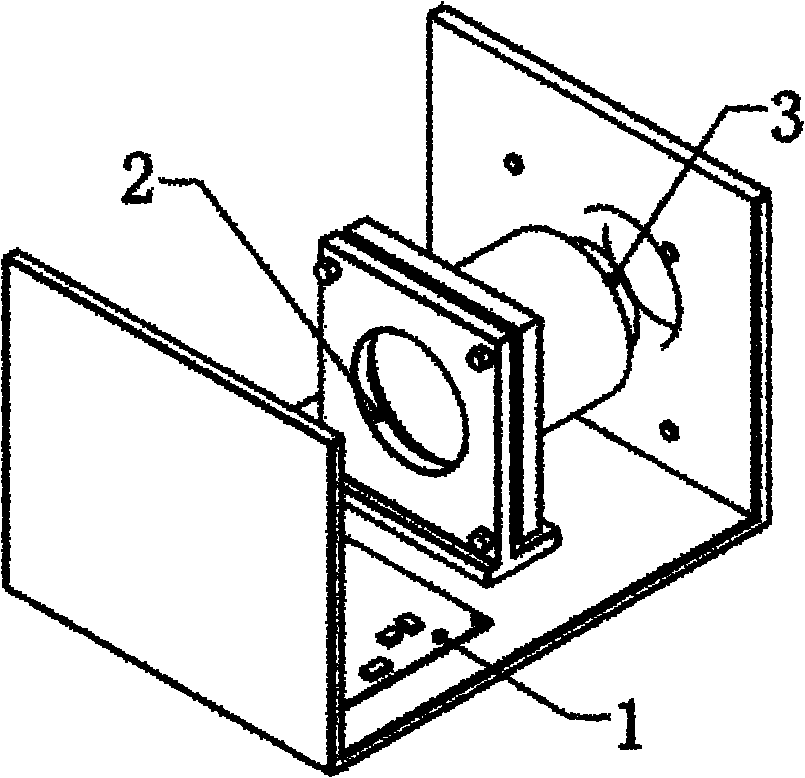

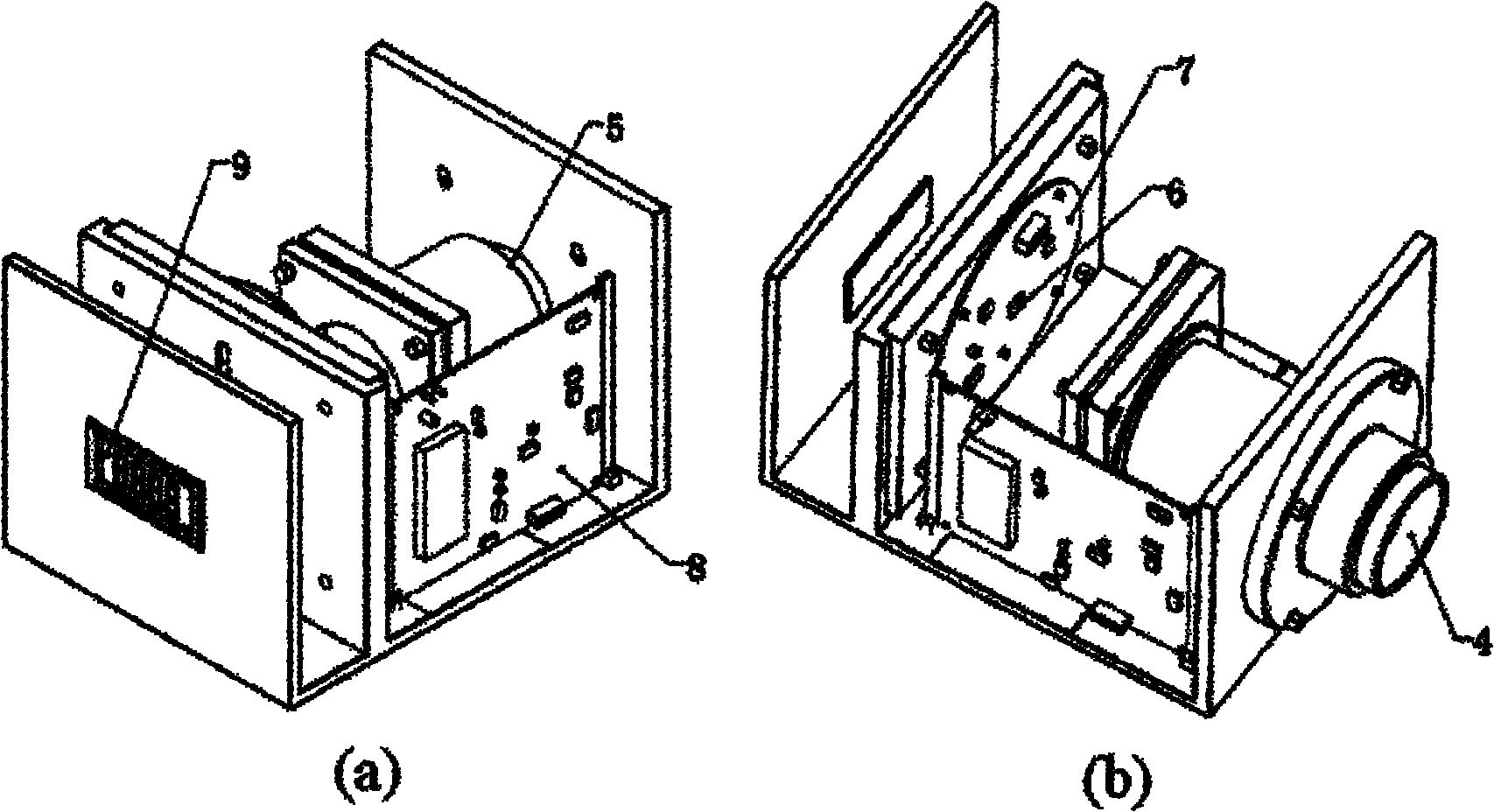

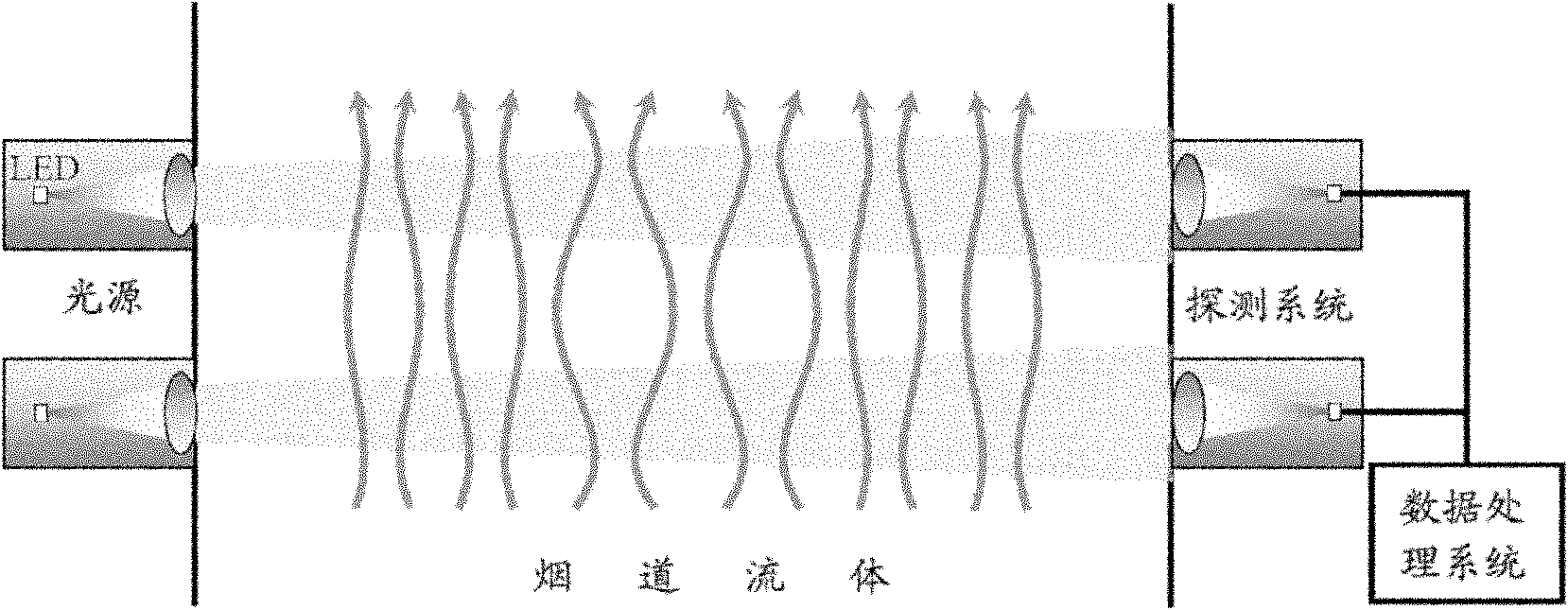

[0033] see figure 1 , 2 , 3, a flue gas flow rate measuring instrument, including two groups of light emitting system and light receiving system located on both sides of the flue, wherein the light emitting system includes an LED light source 2 and a collimating lens located on the outgoing light path of the LED light source 2 3. The light receiving system includes a focusing lens 5 and a photodetector 6 located on the transmission light path of the focusing lens 5. The light beam emitted by the LED light source 2 is collimated by the collimator lens 3 into a parallel beam and then passes through the flue. 5 to receive and send to the photodetector; the photodetector is externally connected to the digital display 9 through the data processing system.

[0034] The LED light source 2 is driven by the constant current source 1; the front end of the focusing lens 5 is equipped with a dust cover 4.

[0035] A method for measuring flue gas flow velocity, specifically comprising th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com