Hydro-conversion integration method for high-nitrogen high-arene oil

A technology of hydroconversion and high aromatics, which is applied in the treatment of hydrocarbon oil, hydroprocessing technology, petroleum industry, etc., and can solve problems such as unreported technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

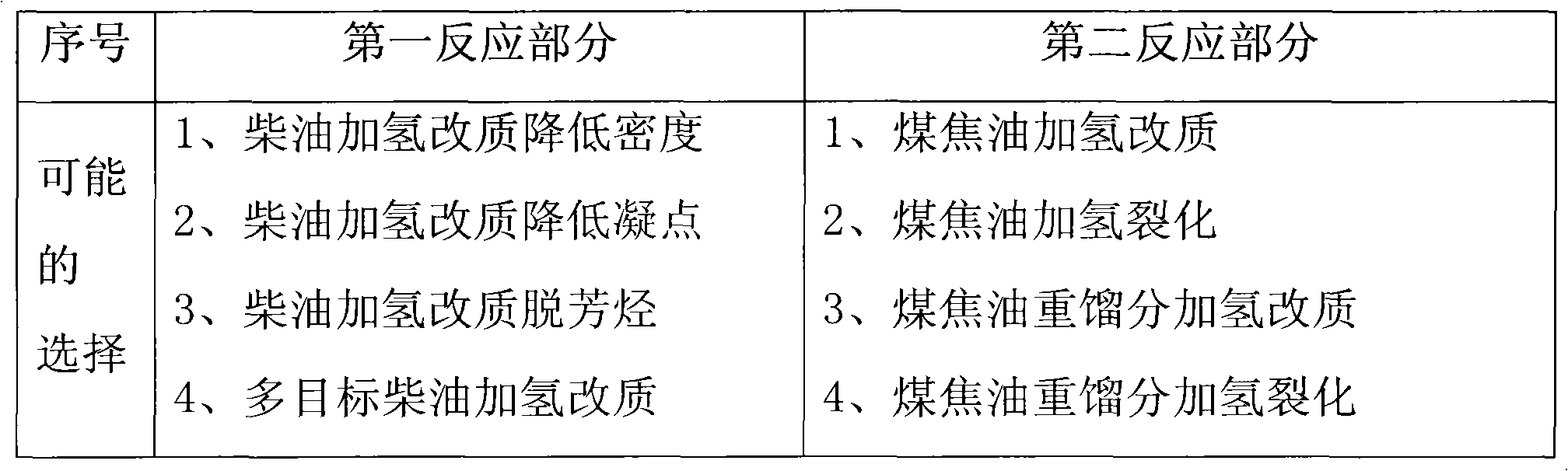

Method used

Image

Examples

Embodiment 1

[0151] The annual start-up of the device is calculated as 8000 hours / year.

[0152] In the second hydrogenation reaction process, the hydrocarbon feedstock F2 is medium-temperature coal tar distillate oil with a boiling range of 165-505°C, the sulfur content of F2 is 0.65% by weight, the nitrogen content is 0.87% by weight, and the flow rate of F2 is 62.5t / h. Hydrogen process raw material hydrocarbon unit hydrogen consumption (including dissolved hydrogen) is 6.25% (43430Nm 3 / h). The F2 hydrocracking process adopts a two-stage processing process. The first stage is a hydro-upgrading process, and the second stage is a "heavy diesel oil + wax oil" (hydro-upgraded wax oil with a conventional boiling point between 350-505°C). Hydrogen cracking process. The hydrogenation reaction conditions of the first-stage hydrogenation upgrading process are: high-pressure conditions with a temperature of 320-400°C and a pressure of 16.0-18.0MPa, and the hydrogen volume at the inlet of the fi...

Embodiment 2

[0164] The annual start-up of the device is calculated as 8000 hours / year.

[0165] The second hydroconversion section is basically the same as in Example 1. In the second hydrogenation reaction process, the hydrocarbon raw material F2 is a medium-temperature coal tar distillate oil with a boiling range of 165-505°C. The F2 hydrocracking process adopts a two-stage processing process. It is a hydrocracking process of "heavy diesel oil + wax oil" (hydromodified wax oil with conventional boiling point between 335-505°C).

[0166] The diesel oil conversion product with a boiling point between 170 and 335°C generated in the first-stage hydro-upgrading process is used as the first hydrocarbon feedstock F1 and enters the first reaction part to form a two-stage coal tar hydrogenation combined process.

[0167] The first hydrocarbon material F processed in the first reaction part is the narrow-cut diesel oil in the fractionation part of the second reaction effluent, the narrow-cut die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com