SiO2: RE light-emitting film taking TiO2 nanotube array as carrier and preparation method thereof

A technology of nanotube array and luminescent thin film, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem of low fluorescence efficiency, and achieve the effect of mild process conditions and simple use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation steps of this embodiment are:

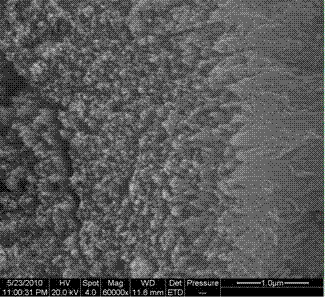

[0060] Step 1, TiO 2 Preparation of nanotube array films:

[0061] (1) Put the titanium sheet whose size is length×width: 40mm×20mm in the acetone solution for ultrasonic cleaning and degreasing, and then clean it with deionized water;

[0062] (2) Put the cleaned titanium sheet into a hydrofluoric acid-nitric acid mixture for chemical polishing to remove the surface oxide film, where the volume ratio of hydrofluoric acid to nitric acid is 1:3;

[0063] (3) Put the chemically polished titanium sheet into absolute ethanol for ultrasonic cleaning;

[0064] (4) Use an aqueous ammonium chloride solution with a concentration of 0.3mol / L as the electrolyte, use a carbon rod (4cm×5cm×0.5cm in size) as the cathode, and use the titanium sheet treated in the above step (3) as the anode. Under the condition of a voltage of 26.6 volts, anodize for 2 minutes to obtain TiO 2 nanotube array films;

[0065] Step 2, preparation of lum...

Embodiment 2

[0077] The preparation steps of this embodiment are:

[0078] Step 1, TiO 2 Preparation of nanotube array films:

[0079] (1) Put the titanium sheet whose size is length×width: 40mm×20mm in an acetone solution for ultrasonic cleaning and degreasing for 5 minutes, and then wash it with deionized water;

[0080] (2) Put the cleaned titanium sheet into the hydrofluoric acid-nitric acid mixture solution for chemical polishing for 30 seconds, wherein the volume ratio of hydrofluoric acid to nitric acid is 1:3;

[0081] (3) Put the chemically polished titanium sheet into absolute ethanol for ultrasonic cleaning;

[0082] (4) Use an aqueous ammonium chloride solution with a concentration of 0.3mol / L as the electrolyte, use a carbon rod (4cm×5cm×0.5cm in size) as the cathode, and use the titanium sheet treated in the above step (3) as the anode. At a voltage of 13.7 volts, anodize for 2 minutes to obtain TiO 2 nanotube array films;

[0083] Step 2, preparation of luminescent film...

Embodiment 3

[0092] The preparation steps of this embodiment are:

[0093] Step 1, TiO 2 Preparation of nanotube array films:

[0094] (1) Put the titanium sheet whose size is length×width: 40mm×20mm in an acetone solution for ultrasonic cleaning and degreasing for 5 minutes, and then wash it with deionized water;

[0095] (2) Put the cleaned titanium sheet into the hydrofluoric acid-nitric acid mixed solution for chemical polishing for 30 seconds to remove the surface oxide film, wherein the volume ratio of hydrofluoric acid to nitric acid is 1:3;

[0096] (3) Put the chemically polished titanium sheet into absolute ethanol for ultrasonic cleaning;

[0097] (4) Use an aqueous ammonium chloride solution with a concentration of 0.1mol / L as the electrolyte, a carbon rod (4cm×5cm×0.5cm in size) as the cathode, and a titanium sheet treated in the above step (3) as the anode, Under the condition of a voltage of 21.6 volts, anodize for 2 minutes to obtain TiO 2 nanotube array films;

[0098...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com