Method for preparing water-based nano silicon resin compound

A technology of nano-silicone resin and nano-oxide, applied in the direction of coating, etc., can solve the problems of exceeding the application standard, failing to meet the national standard, low friction coefficient and wear resistance, etc., and achieve the effect of improving product grade and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

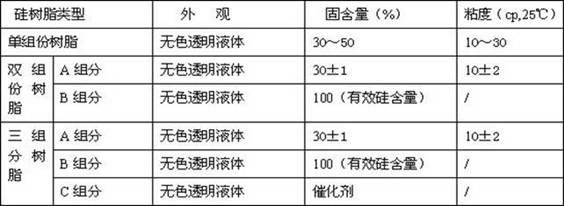

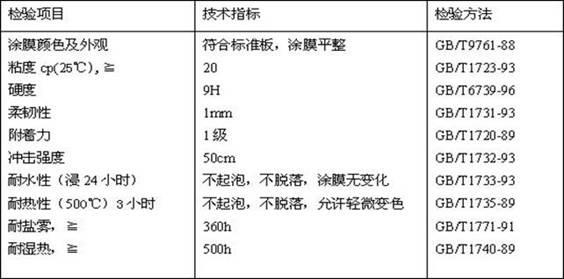

Method used

Image

Examples

Embodiment 1

[0024] Put 500g of methyltriethoxysilane, 20g of phenyltriethoxysilane, 40g of nano-alumina, 12g of phosphotungstic acid and 30g of deionized water in a three-necked flask, and stir and react at 25-30°C for 10 hours. Then add 80 g of deionized water to adjust the viscosity of the solution to 15 cp (25° C.). The obtained colorless and transparent one-component silicone resin has a solid content of 35%.

Embodiment 2

[0026] Put 250kg of methyltrimethoxysilane, 50kg of ethyl orthosilicate, 20kg of nano-silicon oxide, 8kg of silicotungstic acid and 20kg of deionized water into a 500L reactor, stir and react at 25-30°C for 10 hours, then add 50kg deionized water, adjust the solution viscosity to 12cp (25°C). A colorless and transparent one-component silicone resin was obtained, and its solid content was measured to be 31%.

Embodiment 3

[0028] Preparation of two-component water-based nano-silicone resin:

[0029] Component A: Fully mix 25g of nano-alumina, 80g of nano-silicon oxide, 5g of phosphoric acid, 5g of phosphotungstic acid, and 10g of deionized water. The measured solid content is 32%, and the viscosity is 13cp (25°C).

[0030] Component B: 60g of phenyl triethoxysilane, 40g of ethyl orthosilicate, and 30g of octamethylcyclotetrasiloxane.

[0031] Weigh components A and B in equal amounts, mix thoroughly in a high-speed mixer until transparent, and take samples for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com