Ultrasonic auxiliary cutting device with cutter fine adjustment mechanism

A fine-tuning mechanism and ultrasonic-assisted technology, applied in auxiliary devices, accessories of tool holders, turning equipment, etc., can solve the problems of large energy loss and inability to fine-tune the height of the tool tip, and achieve the effect of less energy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

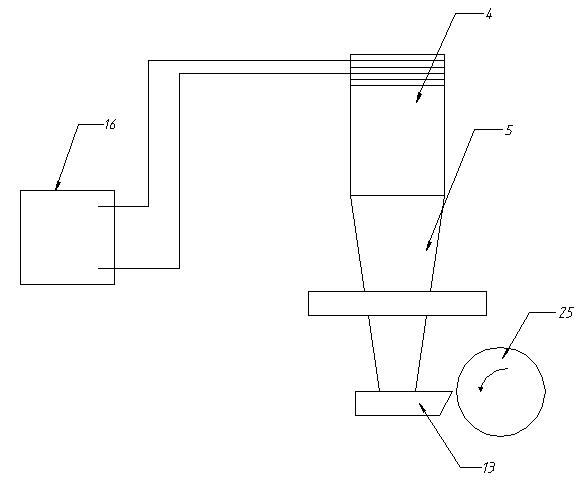

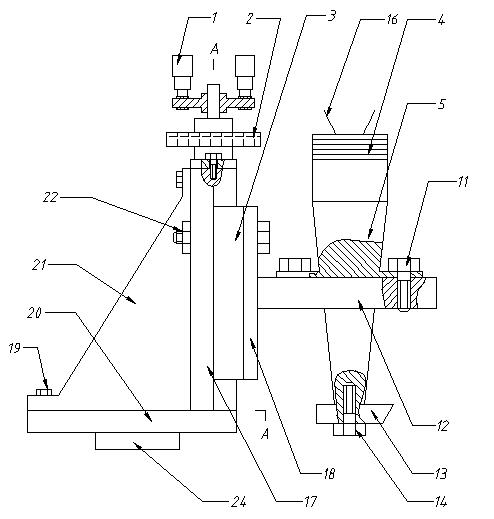

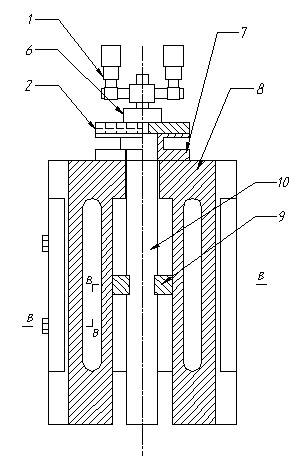

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 The ultrasonic-assisted cutting device with the tool fine-tuning mechanism shown includes the tool fine-tuning mechanism and the ultrasonic vibro-acoustic system, the tool fine-tuning mechanism and the ultrasonic vibro-acoustic system are connected through a flange, and the ultrasonic vibro-acoustic system and the workpiece can be changed by adjusting the tool fine-tuning mechanism 25 relative position.

[0018] Cutter fine-tuning mechanism comprises vertical plate 17 vertically arranged on the base plate 20, and vertical plate 17 both sides is provided with guide rail, and vertical plate 17 is provided with dovetail slide plate 3 by guide rail, and vertical plate 17 is connected with dovetail slide plate 3 by connecting plate 18 threads. In the connecting sleeve 8 in the middle of the vertical plate 17, a screw 10 is provided through a screw nut 9. The pitch P (lead S) of the screw 10 is 1.5 mm. The square groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com