Low-elasticity high-strength near beta-type Ti-Nb-Ta-Zr alloy and preparation method of near beta-type Ti-Nb-Ta-Zr alloy

A ti-nb-ta-zr and alloy technology, which is applied in the field of low elastic modulus near β-type Ti-Nb-Ta-Zr alloy and its preparation, can solve the problems of high toxicity of added elements and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

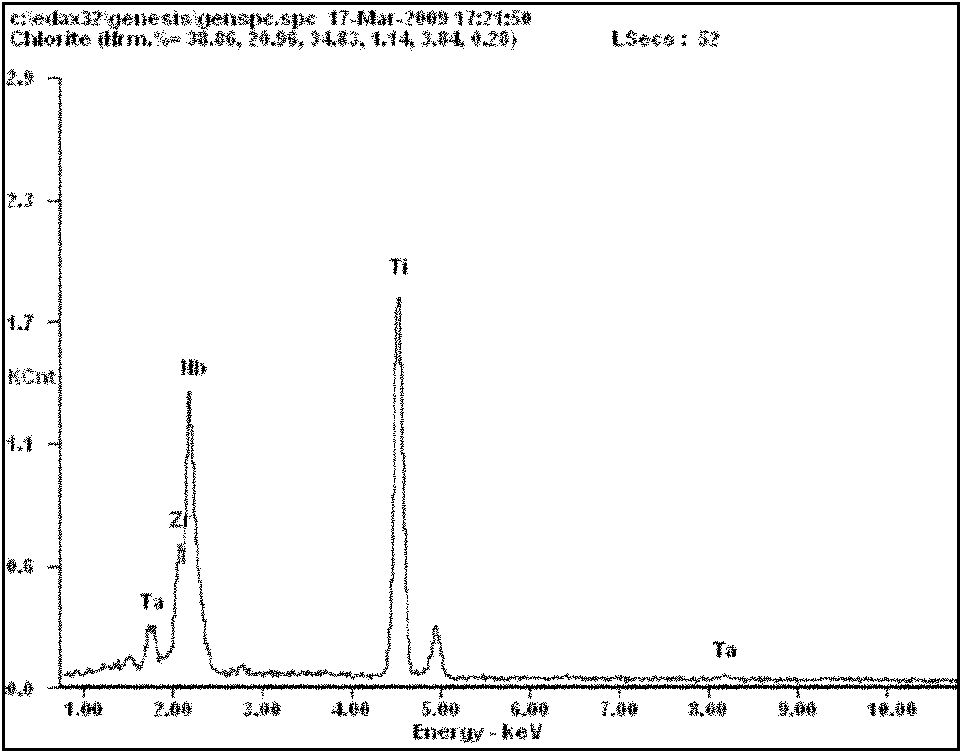

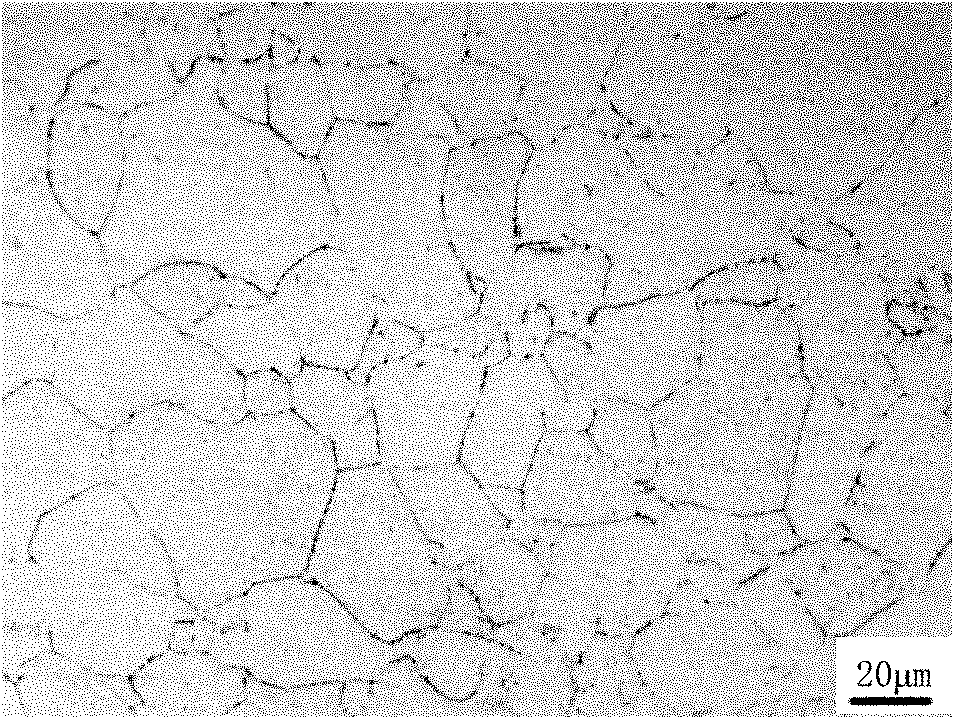

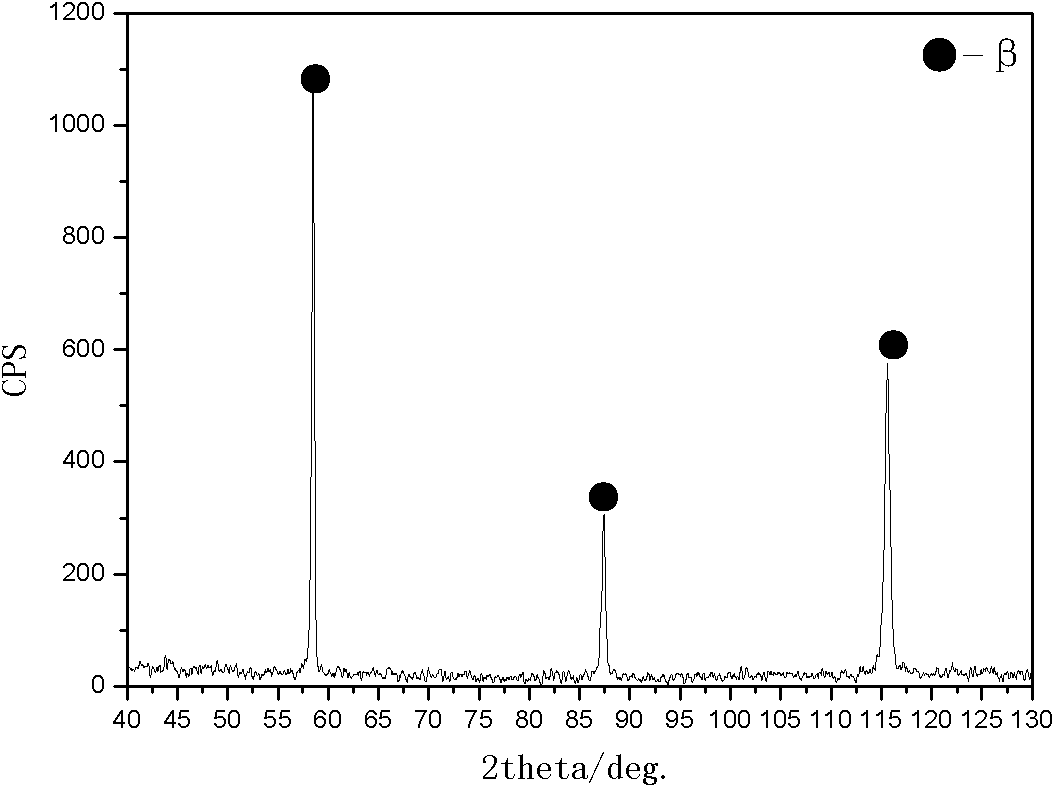

[0027] A) Alloy preparation

[0028] Ti-30Nb-5Ta-9Zr alloy, Ti, Nb, Ta, Zr pure metals are proportioned according to the mass percentage of the alloy composition, melted in a non-consumable vacuum electric arc furnace, fully electromagnetically stirred, the melting voltage is 10-34 volts, and the melting current is 50 -300 amps, the electromagnetic stirring current is 6-12 amps, and the number of melting times is 3-5 times. Button-shaped ingots are obtained after smelting many times.

[0029] B) hot forging

[0030] After the ingot is hot forged, it is forged into a plate with a thickness of 3mm, a length of 70mm, and a width of 30mm, and is cut into a tensile sample by wire.

[0031] C) heat treatment

[0032] The tensile sample was subjected to solution treatment in a box-type resistance furnace, the solution temperature was 750°C, the solution time was 0.5h, and water quenching was carried out after solution.

[0033] D) Material properties

[0034] Elastic modulus (GP...

Embodiment 2

[0036] A) Alloy preparation

[0037] Ti-30Nb-5Ta-12Zr alloy, Ti, Nb, Ta, Zr pure metals are proportioned according to the mass percentage of the alloy composition, melted in a non-consumable vacuum electric arc furnace, fully electromagnetically stirred, the melting voltage is 10-34 volts, and the melting current is 150 -350 amps, the electromagnetic stirring current is 10-15 amps, and the number of melting times is 3-5 times. Button-shaped ingots are obtained after smelting many times.

[0038] B) hot forging

[0039] After the ingot is hot forged, it is forged into a plate with a thickness of 3mm, a length of 70mm, and a width of 30mm, and is cut into a tensile sample by wire.

[0040] C) heat treatment

[0041] The tensile sample was subjected to solution treatment in a box-type resistance furnace, the solution temperature was 800 ° C, the solution time was 1 h, and water quenching was carried out after solution.

[0042] D) Material properties

[0043]Elastic modulus ...

Embodiment 3

[0045] A) Alloy preparation

[0046] Ti-30Nb-5Ta-6Zr alloy, Ti, Nb, Ta, Zr pure metals are proportioned according to the mass percentage of the alloy composition, melted in a non-consumable vacuum electric arc furnace, fully electromagnetically stirred, the melting voltage is 10-34 volts, and the melting current is 100 -300 amps, the electromagnetic stirring current is 8-14 amps, and the number of melting times is 3-5 times. Button-shaped ingots are obtained after smelting many times.

[0047] B) hot forging

[0048] After the ingot is hot forged, it is forged into a plate with a thickness of 3mm, a length of 70mm, and a width of 30mm, and is cut into a tensile sample by wire.

[0049] C) heat treatment

[0050] The tensile sample was subjected to solution treatment in a box-type resistance furnace, the solution temperature was 750°C, the solution time was 0.5h, and water quenching was carried out after solution. The artificial aging temperature is 500°C, the aging time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com