Palygorskite-modified aqueous transfer printing coating and preparation method thereof

A kind of palygorskite and coating technology, applied in the field of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

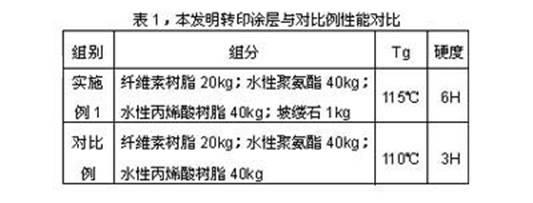

Embodiment 1

[0039] Step 1, the purification of palygorskite

[0040] Mix palygorskite powder and deionized water at a ratio of 1:20 (weight ratio), stir mechanically for 30 minutes, let stand for 1 hour, pour out the upper liquid, and repeat the operation 5 times.

[0041] After adding water, stir mechanically again for 30 minutes, pour out the upper layer of suspension, sonicate the suspension for 40 minutes, pour it into a clean tray to air dry naturally, ball mill for 30 minutes, and vacuum dry at 110°C for 2 hours.

[0042] Step 2, prepare transfer coating slurry

[0043] Cellulose resin 20kg;

[0044] Water-based polyurethane 40 kg;

[0045] Water-based acrylic resin 40 kg;

[0046] Mix the above water-based resins.

[0047] Step 3, add palygorskite

[0048] 1 kg of palygorskite purified in step 1 was added to the slurry and stirred for 2 hours, and discharged.

[0049] Step 4, Coating

[0050] The mixture obtained in step 3 is coated on a coating machine.

[0051] At the sam...

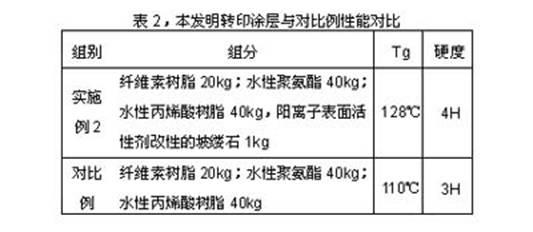

Embodiment 2

[0056] Step 1, cationic surfactant modified palygorskite

[0057] The cationic surfactant is exemplified by cetyltrimethylammonium bromide.

[0058] Mix palygorskite powder and deionized water in a ratio of 1:20 (weight ratio) to prepare palygorskite suspension, raise the temperature to 90°C, add cetyltrimethylammonium bromide (mass 2% of the mass of palygorskite), stirred and reacted; the pH value was adjusted to 9, the obtained slurry was filtered, washed, then dried and pulverized to obtain cationic surfactant-modified palygorskite powder.

[0059] Step 2, prepare transfer coating slurry

[0060] Cellulose resin 20kg;

[0061] Water-based polyurethane 40 kg;

[0062] Water-based acrylic resin 40 kg;

[0063] Mix the above water-based resins.

[0064] Step 3, add palygorskite

[0065] Add 1kg of palygorskite modified in step 1 into the slurry and stir for 2h, then discharge.

[0066] Step 4, Coating

[0067] The mixture obtained in step 3 is coated on a coating machi...

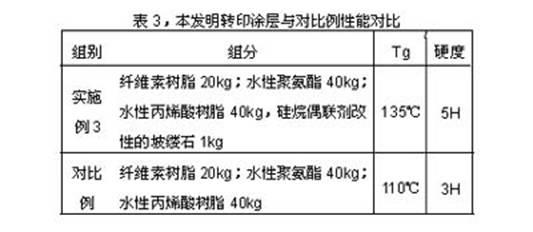

Embodiment 3

[0073] Step 1, silane coupling agent modified palygorskite

[0074] The silane coupling agent is γ-aminopropyltriethoxysilane as an example.

[0075] Mix palygorskite powder and deionized water in a ratio of 1:10 (weight ratio) to prepare palygorskite suspension, raise the temperature to 90°C, add γ-aminopropyltriethoxysilane (mass is 10% of the mass of attapulgite), stirred and reacted; the obtained slurry was filtered, washed, then dried and pulverized to obtain palygorskite powder modified by a silane coupling agent.

[0076] Step 2, prepare transfer coating slurry

[0077] Cellulose resin 20kg;

[0078] Water-based polyurethane 40 kg;

[0079] Water-based acrylic resin 40 kg;

[0080] Mix the above water-based resins.

[0081] Step 3, add palygorskite

[0082] Add 1kg of palygorskite modified in step 1 into the slurry and stir for 2h, then discharge.

[0083] Step 4, Coating

[0084] The mixture obtained in step 3 is coated on a coating machine.

[0085] At the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com