Protic ionic liquid, preparation method and application of protic ionic liquid in cellulose dissolution and regeneration

A technology of dissolving cellulose and ionic liquid, applied in the direction of artificial filament in cellulose solution, wet spinning method, etc., can solve the problems of uneven quality, difficult solvent recovery, defective fiber structure, etc., and achieves simple processing technology, The effect of low price and improved quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

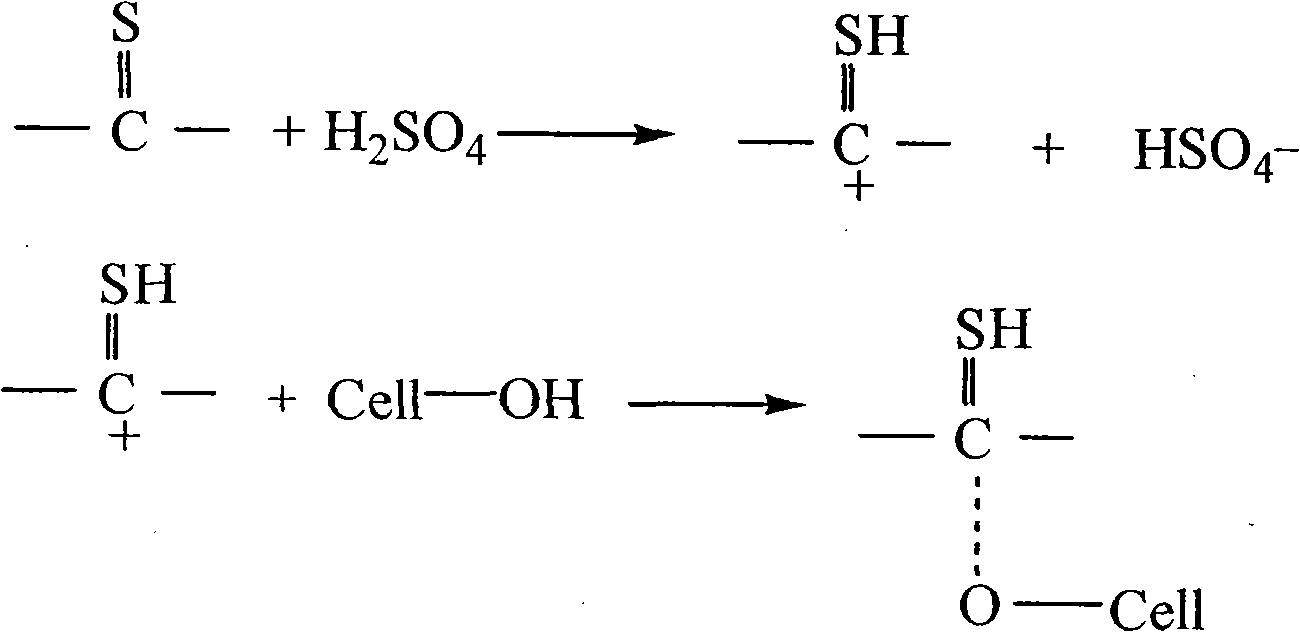

Method used

Image

Examples

Embodiment 1

[0027] Weigh 7.6 grams of ammonium thiocyanate and 9.8 to 49 grams of concentrated sulfuric acid with a mass fraction of 98%. Place the sulfuric acid in an ice-water bath, and then slowly add ammonium thiocyanate to the sulfuric acid. After the addition is complete, stir slowly until the ammonium thiocyanate is completely dissolved. Weigh 10 grams of the synthesized ionic liquid, place it in a heating mantle and raise the temperature to 30-60° C. to keep it warm. Weigh 0.5-3 grams of cotton fiber, add the cotton fiber to the ionic liquid bit by bit, and then stir until the cellulose is completely dissolved. The dissolved cellulose is spun through a spinning machine using wet spinning technology and regenerated and coagulated in an ethanol coagulation bath. The solvent containing ethanol can be heated to remove ethanol, and the pure ionic liquid solvent can be recovered.

Embodiment 2

[0029] Weigh 7.6 grams of thiourea and 9.8 to 49 grams of concentrated sulfuric acid with a mass fraction of 98%. Slowly add sulfuric acid dropwise to thiourea. After the dropwise addition, stir slowly until the thiourea is completely dissolved. Weigh 10 grams of the synthesized ionic liquid, place it in a heating mantle and raise the temperature to 30-60° C. to keep it warm. Weigh 3 grams of cotton fiber, add the cotton fiber to the ionic liquid little by little, and then stir until the cellulose is completely dissolved. The solvent containing ethanol can be heated to remove ethanol, and the pure ionic liquid solvent can be recovered.

Embodiment 3

[0031] Weigh 7.3 grams of thioacetamide and 9.8 to 49 grams of concentrated sulfuric acid with a mass fraction of 98%. Slowly add sulfuric acid dropwise to thioacetamide. After the dropwise addition, stir slowly until the thioacetamide is completely dissolved. Weigh 10 grams of the synthesized ionic liquid, place it in a heating mantle and raise the temperature to 30-60° C. to keep it warm. Weigh 0.5-3 grams of cotton fiber, add the cotton fiber to the ionic liquid bit by bit, and then stir until the cellulose is completely dissolved. The ethanol-containing solvent is removed by heating, and the pure ionic liquid solvent is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com