Novel scale inhibition and dispersion agent

A scale inhibitor and dispersant, a new type of technology, applied in the field of scale inhibitor, to achieve the effects of stable and reliable process, cost reduction and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

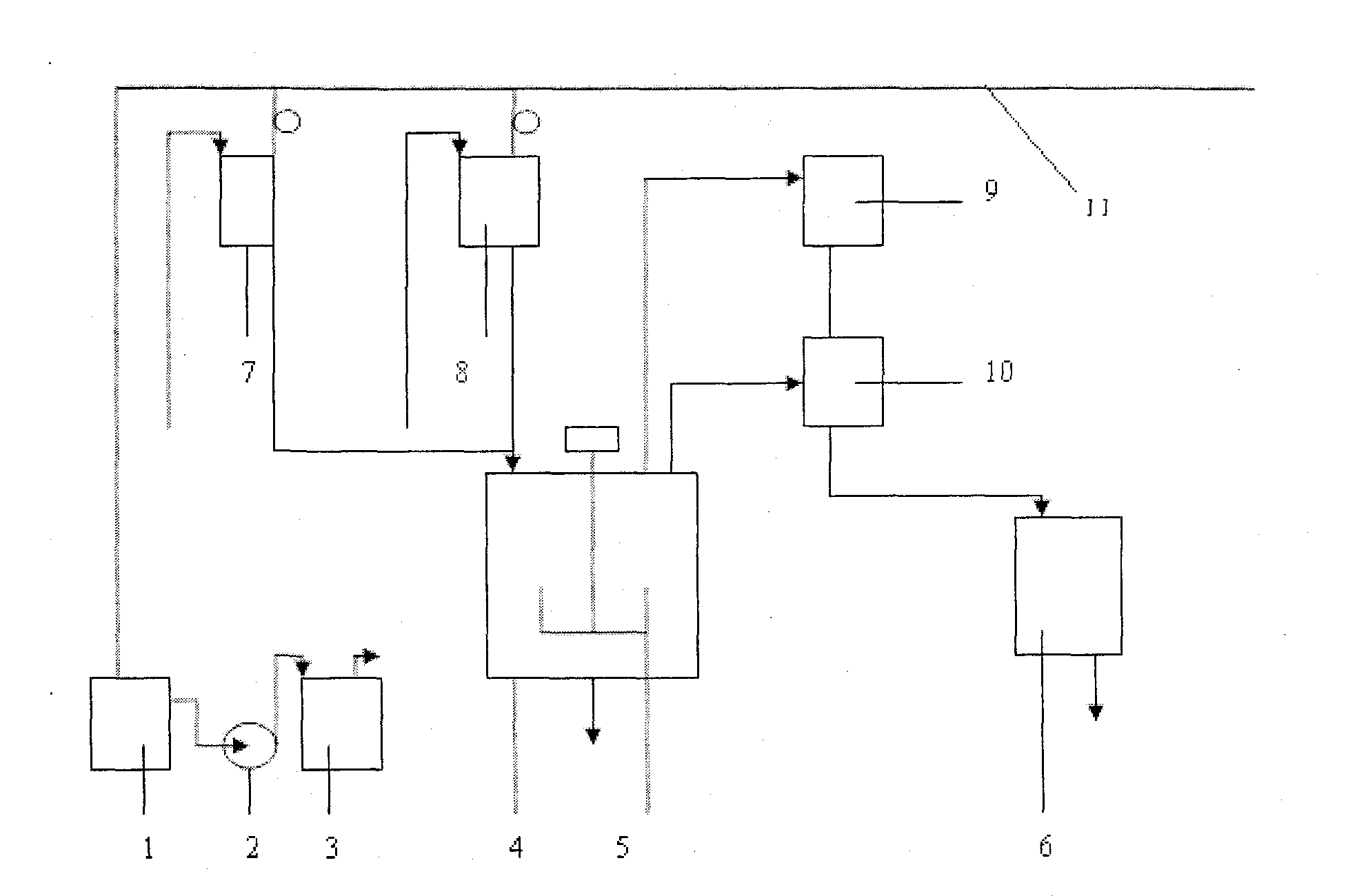

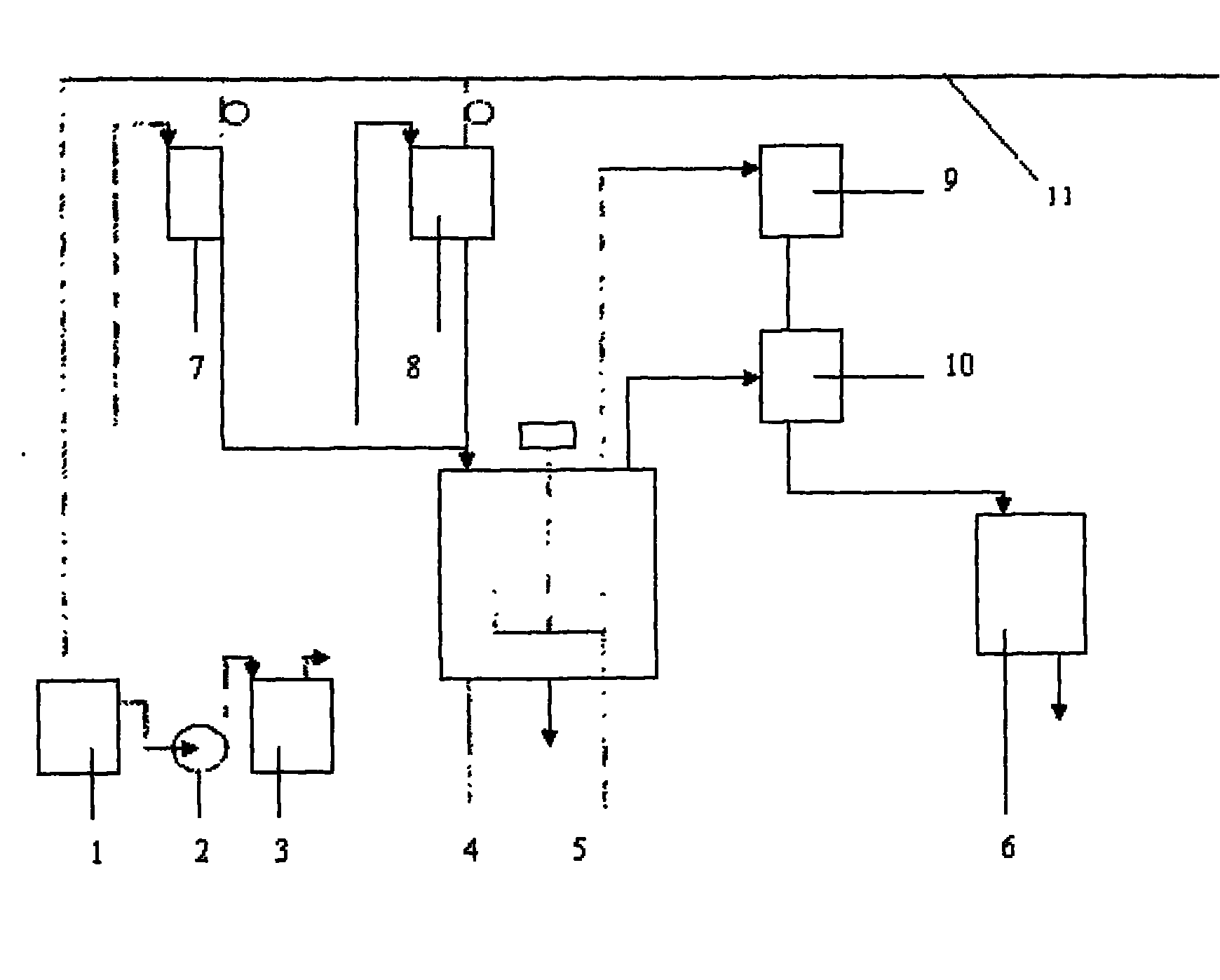

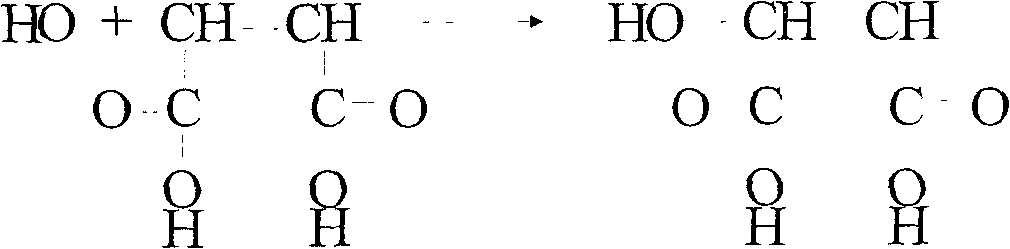

Method used

Image

Examples

Embodiment 1

[0038] 65 grams of maleic anhydride (purity 99.5%) and 32.5 grams of sulfamic acid (purity 99%) are added in 500 milliliters of four-port glass reaction preparation equipments under stirring state, under CO2 gas protection, begin slow heating, with 30 Heat to 60-80°C in minutes and maintain for 1 hour. Then it takes 1 hour to raise the temperature to 100-110° C. and carry out the ammonolysis reaction for 1 hour. Cool down to 60°C, add 60 grams of water, then add 5 mg each of self-made catalysts TL-A and TL-B, then add 25 grams of sodium hypophosphite (purity 99%), and divide sodium hypophosphite three times at 60°C After the addition was complete, the temperature was raised to 90°C. Under the condition of 90°C, start to add the initiator peroxide dropwise at a constant speed, and the aqueous solution of 21 grams (30%) of the initiator peroxide is added dropwise in 3 hours, and the reaction temperature is controlled at 100-110°C, and then kept at 100-110°C React for 2 hours. ...

Embodiment 2

[0040] Earlier maleic anhydride (purity 99.5%) 72.5 grams and sulfamic acid (purity 99%) 25 grams are added in 500 milliliters of four-port glass reaction preparation equipments under stirring state, under CO Under gas protection, begin to heat slowly, with 30 Heat to 60-80°C in minutes and maintain for 1 hour. Then it takes 1 hour to raise the temperature to 100-110° C. and carry out the ammonolysis reaction for 1 hour. Cool down to 60°C, add 60 grams of water, then add 5 mg each of self-made catalysts TL-A and TL-B, then add 25 grams of sodium hypophosphite (purity 99%), and divide sodium hypophosphite three times at 60°C After the addition was complete, the temperature was raised to 90°C. Under the condition of 90°C, the initiator peroxide was added dropwise at a constant speed, and the aqueous solution of 21 grams (30%) of the initiator peroxide was added dropwise in 3 hours, and the reaction temperature was controlled at 100-110°C, and then kept at 100-110°C React for 2...

Embodiment 3

[0042]First add 60 grams of maleic anhydride (purity 99.5%) and 20 grams of sulfamic acid (purity 99%) into 500ml four-port glass reaction production equipment under stirring, and start to slowly heat under CO2 gas protection for 30 minutes Time to heat to 60-80°C for 1 hour. Then it takes 1 hour to raise the temperature to 100-110° C. and carry out the ammonolysis reaction for 1 hour. Cool down to 60°C, add 60 grams of water, add 17.5 grams of sulfuric acid, then add 5 mg of self-made catalysts TL-A and TL-B, then add 25 grams of sodium hypophosphite (purity 99%), sodium hypophosphite at 60 Under the condition of ℃, the addition was completed three times, and the temperature was raised to 90 ℃. Under the condition of 90°C, the initiator peroxide was added dropwise at a constant speed, and the aqueous solution of 21 grams (30%) of the initiator peroxide was added dropwise in 3 hours, and the reaction temperature was controlled at 100-110°C, and then kept at 100-110°C React f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com