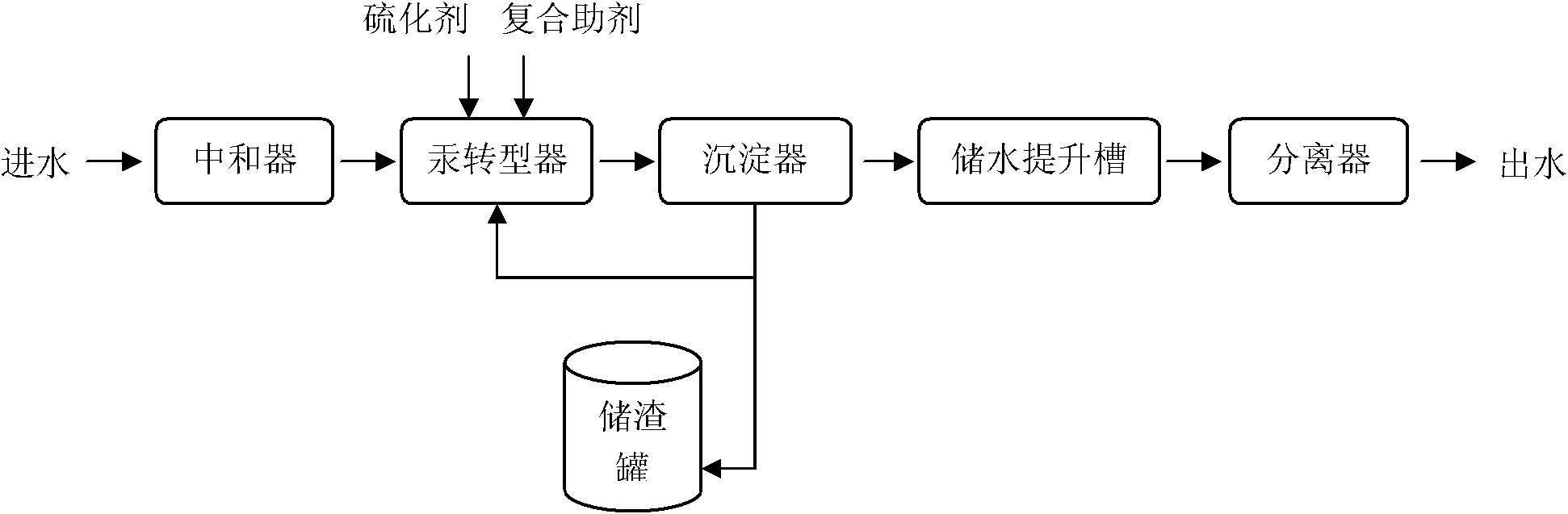

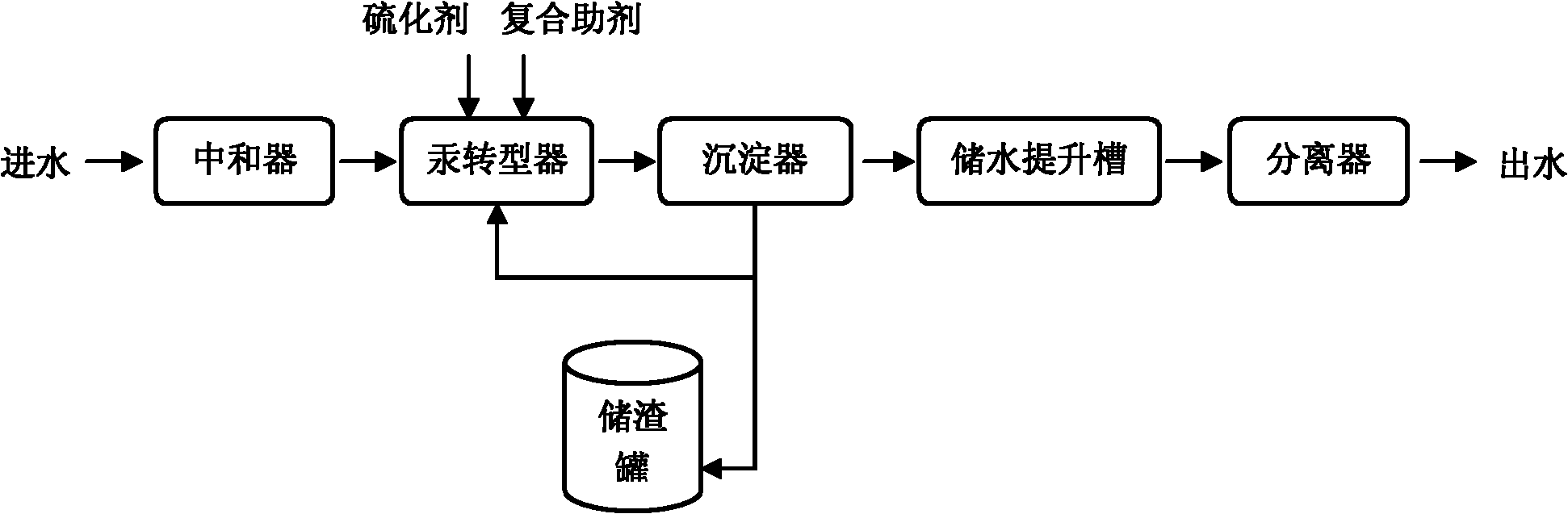

Treatment method of mercury-containing wastewater

A treatment method and technology for wastewater, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the mercury removal process cannot stably meet the discharge requirements, and achieve good economic benefits and social benefits. Benefit, low consumption of chemicals, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raise the mercury-containing waste water that the original Hg content is 40.54mg / L to the neutralizer, adjust its pH to neutral and enter the reactor by gravity, and add an industrial grade vulcanizing agent (Na 2 S), aluminum, iron, calcium sulfate and activated carbon composite additives (aluminum ion: iron ion: calcium ion: activated carbon weight ratio = 1: 0.7: 0.5: 3.8), the supernatant after staying in the sedimentation tank for 20min Self-flow enters the water storage and lifting tank, and is lifted by the pump to achieve continuous water outlet through the sand filter column with a particle size of 0.7-1.2mm. The outlet water is measured by cold atomic absorption method using F732 cold atomic mercury detector according to GB7468-87 standard, and the mercury content is 0.00012- 0.00036mg / L, meeting the emission requirements of the national standard below 0.005mg / L.

[0026] The compounding aid after use can fix Na 2 S is recycled in the system, and when the mer...

Embodiment 2

[0028] Elevate the mercury-containing wastewater with an original Hg content of 1.27mg / L to the neutralizer, adjust its pH to neutral, then flow into the reactor by itself, and add industrial-grade sulfurizing agent (NaHS), aluminum, iron, and calcium into the reactor Halide and activated carbon compound additives (aluminum ion: iron ion: calcium ion: activated carbon weight ratio = 1: 1.2: 0.3: 5.0), after staying for 30 minutes, the supernatant flows into the water storage lifting tank by itself, and is pumped The continuous effluent is realized through the precision filter, and the effluent is measured by the cold atomic absorption method using the F732 cold atom mercury detector according to the GB7468-87 standard, and the mercury content is 0.00042-0.0014mg / L. Meet the emission requirements of the national standard less than 0.005mg / L.

[0029] The compounding aid after use can fix Na 2 S is recycled in the system, and when the mercury content in the granular sediment re...

Embodiment 3

[0031] Elevate the mercury-containing wastewater with an original Hg content of 0.066mg / L to the neutralizer, adjust its pH to neutral, then flow into the reactor by itself, and add industrial-grade sulfurizing agent (NaHS), aluminum, iron, and calcium into the reactor The composite additive composed of sulfate and activated carbon (aluminum ion: iron ion: calcium ion: activated carbon weight ratio = 1: 1.0: 0.4: 4.5), after staying for 15 minutes, the supernatant enters the water storage lifting tank and is lifted by the pump The sand filter column with a particle size of 0.7-1.2mm realizes continuous effluent, and the effluent is measured by cold atomic absorption method and F732 cold atom mercury detector according to GB7468-87 standard, and the mercury content is 0.00037-0.00101mg / L. Meet the emission requirements of the national standard less than 0.005mg / L.

[0032] The used composite additive can fix the vulcanizing agent to be recycled in the system, and when the mercu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com