Cleaning agent for ceramic filter plate and cleaning method thereof

A cleaning agent and filter plate technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems ranging from a few days to less than a month, ineffective, expensive, etc., to reduce cleaning frequency , restore the filtration flux, and reduce the effect of concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

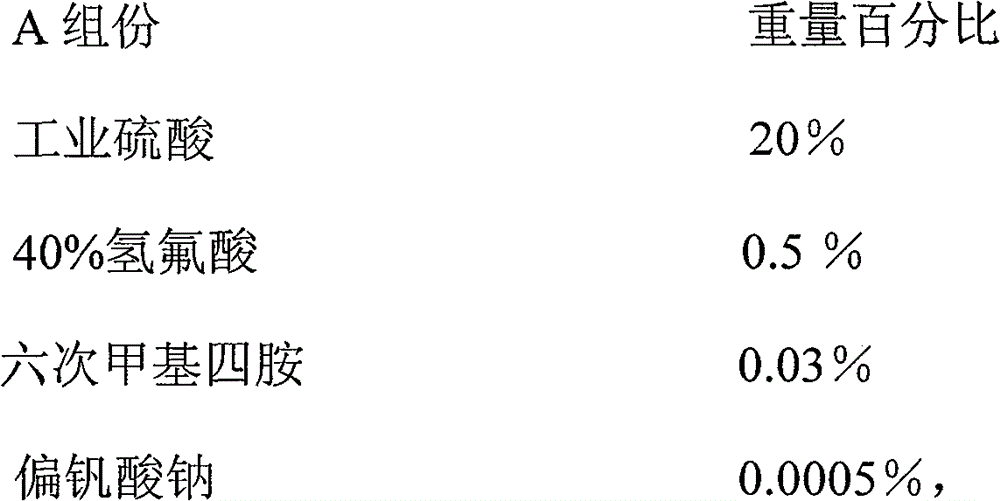

Embodiment 1

[0018] Cleaning step one:

[0019]

[0020] the rest is water;

[0021] Cleaning: Use a pump to send component A of the cleaning agent to the tank of the filter until it is 5cm below the overflow port, start the filter rotor, drive the filter plate to rotate, the ceramic filter plate passes through the tank periodically, and start the ultrasonic waves intermittently The cleaning device cleans, the intermittent time can be set to 20min / h, and component A is discharged after cleaning for 0.5-1h;

[0022] Cleaning step two:

[0023]

[0024]

[0025] the rest is water;

[0026] Cleaning: Use the pump to send the component B of the cleaning agent to the tank of the filter until it is 5cm below the overflow port, start the rotor of the filter, drive the filter plate to rotate, the ceramic filter plate passes through the tank periodically, and enable joint cleaning, The intermittent time can be set to 20min / h, after cleaning for 1-1.5h, component B is discharged, and the...

Embodiment 2

[0028] Cleaning step one:

[0029]

[0030] the rest is water;

[0031] Cleaning method: Use a pump to send component A of the cleaning agent to the tank of the filter until it is 5cm below the overflow port, start the rotor of the filter, drive the filter plate to rotate, and the ceramic filter plate passes through the tank periodically and starts intermittently Ultrasonic cleaning device cleaning, the intermittent time can be set to 20min / h, and component A is discharged after cleaning for 0.5-1h;

[0032] Cleaning step two:

[0033]

[0034]

[0035] Cleaning: Use the pump to send the component B of the cleaning agent to the tank of the filter until it is 5cm below the overflow port, start the rotor of the filter, drive the filter plate to rotate, the ceramic filter plate passes through the tank periodically, and enable joint cleaning, The intermittent time can be set to 20min / h, and component B is discharged after cleaning for 1-1.5h; the whole cleaning is compl...

Embodiment 3

[0037] Cleaning step one:

[0038]

[0039] the rest is water;

[0040] Cleaning: Use a pump to send component A of the cleaning agent to the tank of the filter until it is 5cm below the overflow port, start the filter rotor, drive the filter plate to rotate, the ceramic filter plate passes through the tank periodically, and start the ultrasonic waves intermittently The cleaning device cleans, the intermittent time can be set to 20min / h, and component A is discharged after cleaning for 0.5-1h;

[0041] Cleaning step two:

[0042]

[0043] the rest is water;

[0044] Cleaning method: use the pump to send the component B of the cleaning agent to the tank of the filter until it is 5cm below the overflow port, start the rotor of the filter, drive the filter plate to rotate, the ceramic filter plate passes through the tank periodically, and enable combined cleaning , the intermittent time can be set to 20min / h, after cleaning for 1-1.5h, component B is discharged; the whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com