Perovskite structure film with giant magneto-impedance effect and preparation method thereof

A technology of perovskite structure and giant magneto-impedance, applied in the application of magnetic film to substrate, magnetic layer, etc., can solve the problems of complex preparation process and expensive target material, and achieve simple preparation method, low cost and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

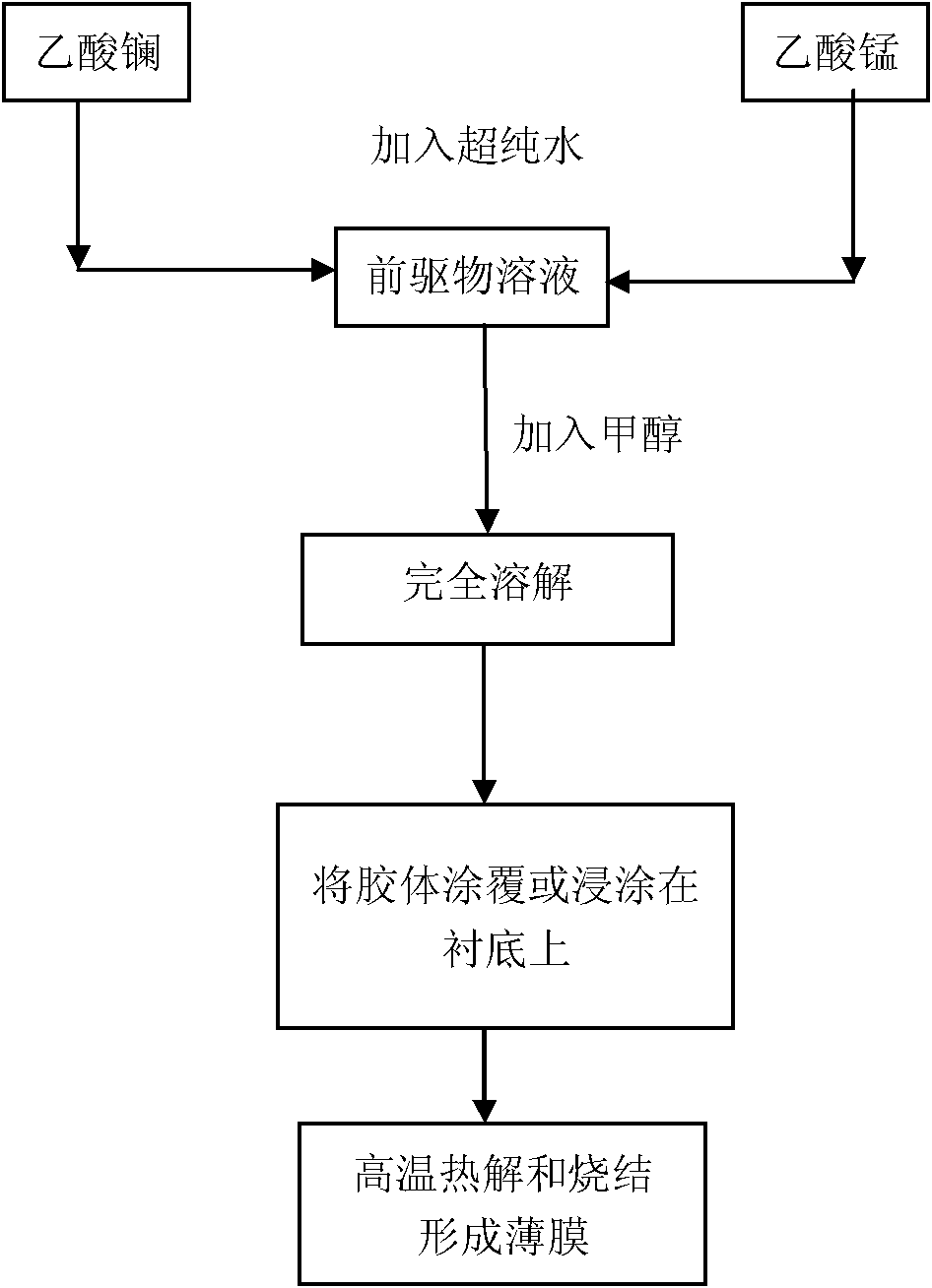

[0031] The invention provides a method for preparing a perovskite structure thin film with a giant magneto-impedance effect, the preparation method process is as follows image 3 As shown, it is realized through the following steps:

[0032] The first step is to determine the volume V of the film sol to be prepared and the concentration M of the substance, and then obtain the quantity n of the substance of the film sol to be prepared.

[0033] In the second step, according to the amount n of the thin film sol to be prepared, the amount of the required metal ion is obtained, and the organic alkoxide compound containing the required metal ion is used as a precursor, and the precursor is dissolved in the super Stir and dissolve in pure water to obtain a precursor solution; the volume of the ultrapure water is 1 / 4 of the volume of the thin film sol, ie 1 / 4V. The precursors are selected from lanthanum acetate and manganese acetate.

[0034] In the third step, methanol is added dr...

Embodiment 1

[0037] Example 1: Utilize the method provided by the invention to carry out LaMnO x Film preparation:

[0038] The first step is to determine that the film sol to be prepared is LaMnO x The sol has a volume V of 100 mL and a concentration of 0.25 mol / L.

[0039]The second step is to use an electronic scale to weigh the precursors as 8.57625g of lanthanum acetate and 6.127g of manganese acetate, and dissolve the lanthanum acetate and manganese acetate in ultrapure water at the same time to obtain the precursor solution. The volume of the ultrapure water is 1 / 4V=25mL.

[0040] In the third step, dropwise methanol into the precursor solution, after adding 20 mL of methanol, the precursor is completely dissolved to form a transparent sol solution.

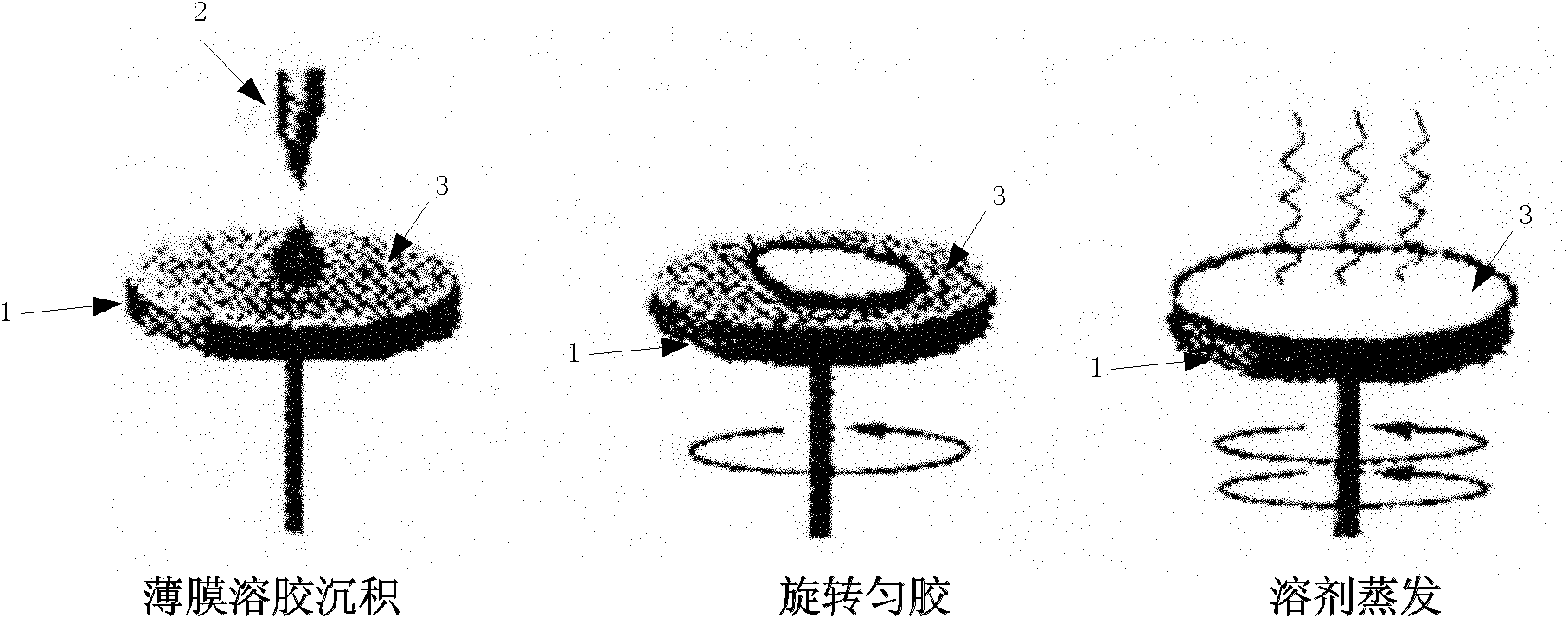

[0041] In the fourth step, the prepared transparent sol solution is coated on the substrate by spin coating, and after pyrolysis and high-temperature sintering in a tubular constant temperature furnace, the required perovskite str...

Embodiment 2

[0047] Example 2: Utilize the preparation method provided by the invention to carry out LaMnO x / Ni / LaMnO x Film preparation:

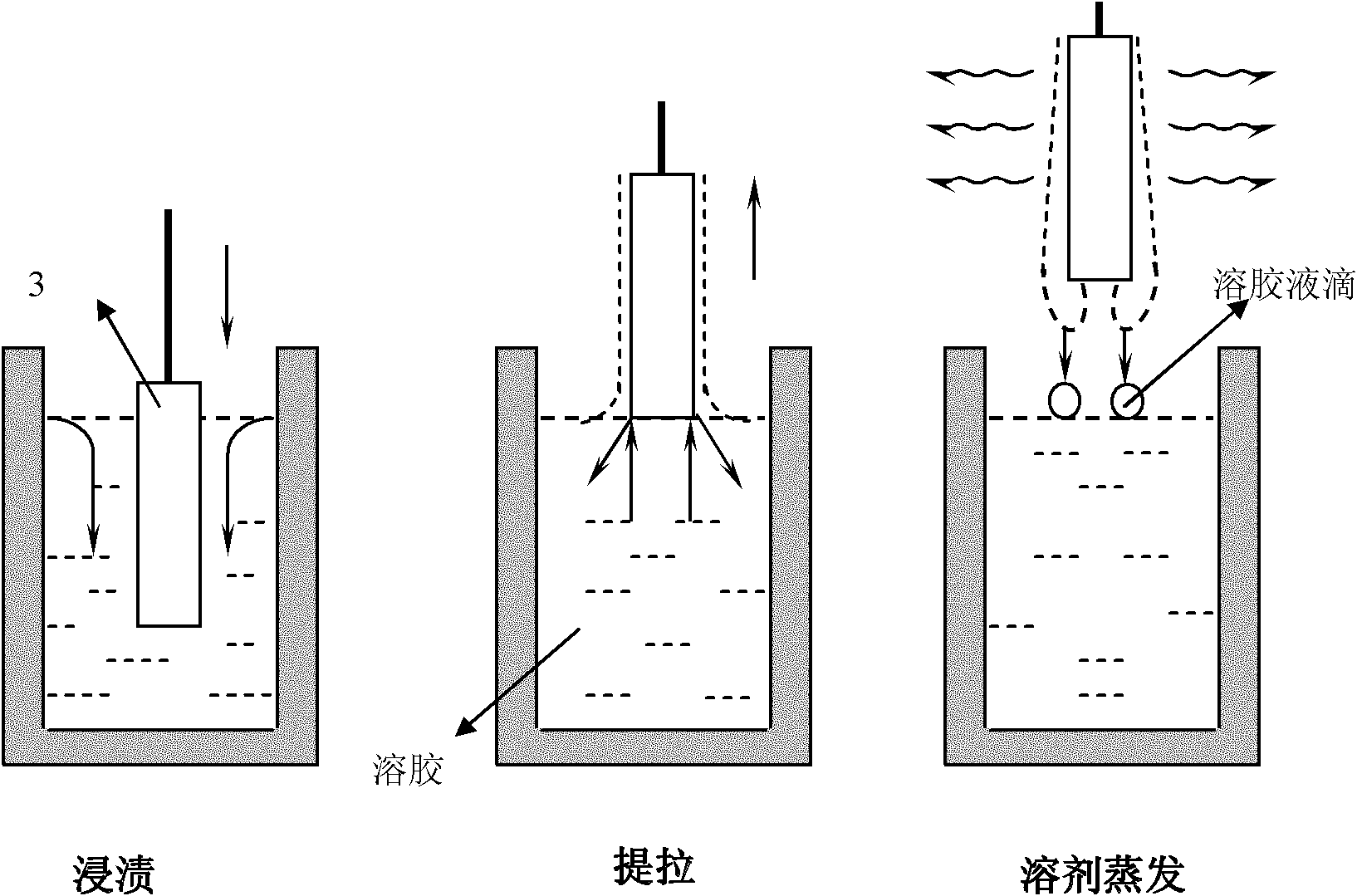

[0048] figure 2 Schematic diagram of film preparation for the pulling method.

[0049] With the thin film sol of preparation in embodiment 1, by figure 2 The shown pulling method is carried out thin film preparation, specifically:

[0050] (1) Dipping: clamp the substrate 3 vertically in the clamp 4 of the puller, and dip the substrate 3 in the film sol. Adjust the parameters of the lifting machine: the ascending speed is 60mm / min, the descending speed is 40mm / min, the stroke is 30mm, and the intermediate waiting time is 5s.

[0051] (2) Pulling: After the adjustment is completed, run the pulling machine to coat the two sides of the Ni-W (W content is 5wt.%) substrate 3 with the thin film sol.

[0052] (3) Solvent evaporation: place the substrate 3 coated with thin film sol on a hollow ceramic plate, then put it into a tube-type constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com