High cleanness methanol diesel and preparation method thereof

A methanol and diesel technology, which is applied to the composition and preparation of high-clean methanol diesel, can solve the problems of perishable stratification, low calorific value, strong hydrophilicity, etc., and achieves the effects of stable operation, stable storage and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] National standard diesel oil 76wt%, methanol 12wt%, co-solvent 10wt%, methyl tert-butyl ether 2wt%, ethyl nitrate 0.02wt%. Wherein, the preparation ratio of methanol diesel co-solvent: vegetable oleic acid 25wt%, fatty acid methyl ester 10wt%, formaldehyde fat 10wt%, cyclohexylamine 5wt%, aviation kerosene 50wt%.

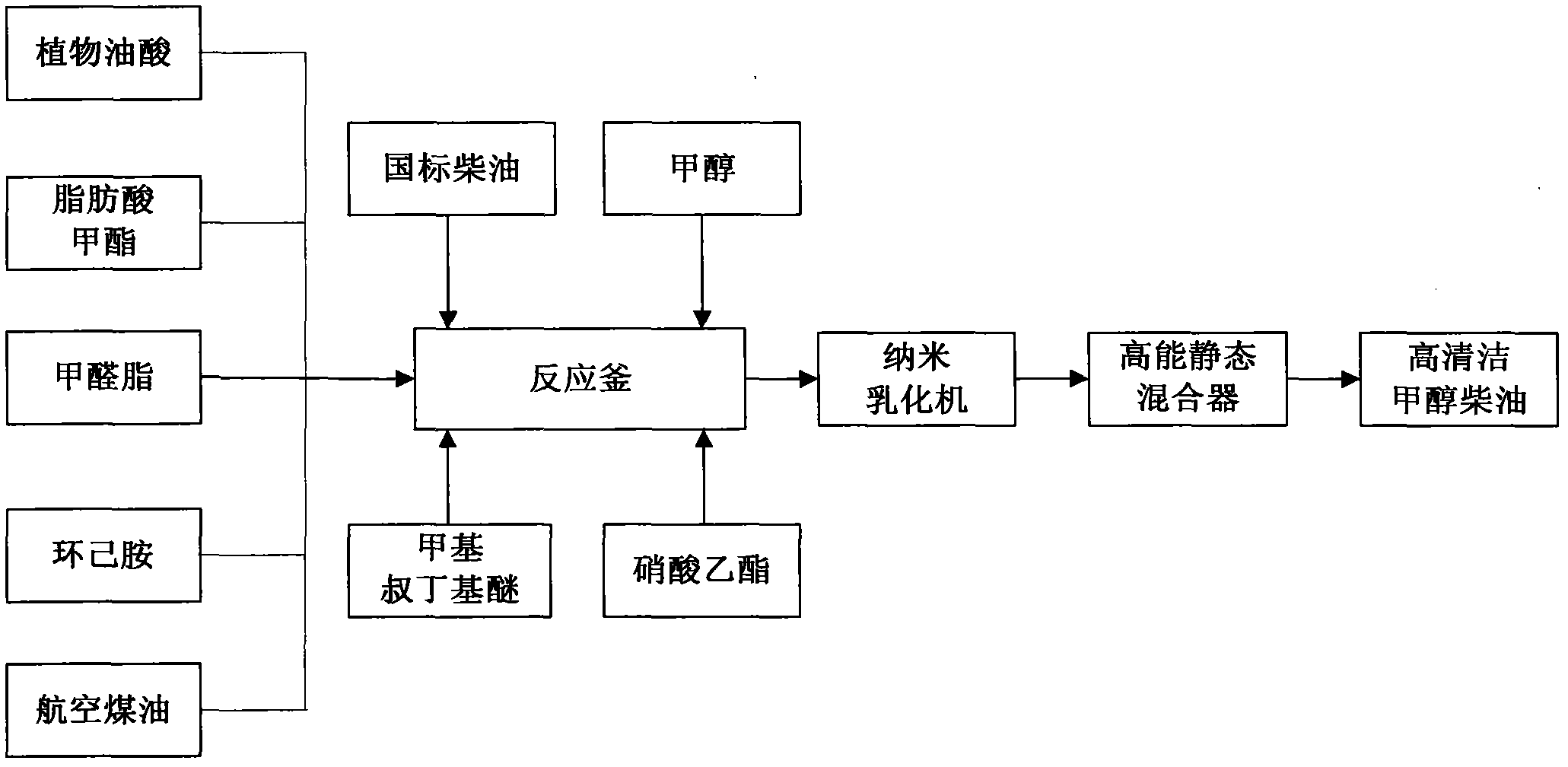

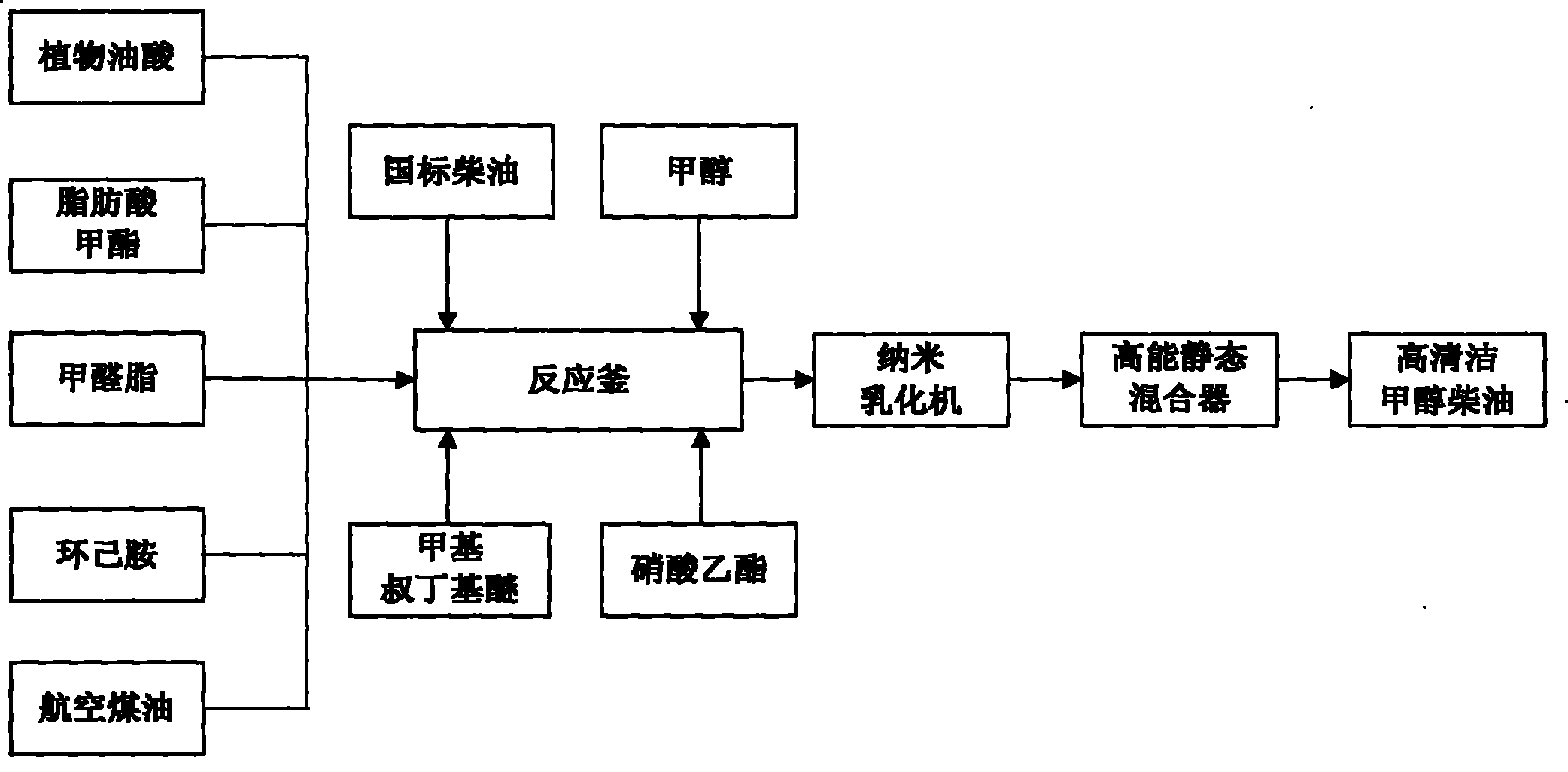

[0015] Preparation method: as shown in the figure, add 12% methanol and 10% co-solvent to the reaction kettle in sequence, and start the stirrer for mixing (stirrer speed 30r / min). After 10 minutes, add 76% of national standard diesel oil, 2wt% of methyl tert-butyl ether, and 0.02wt% of ethyl nitrate in sequence, and continue to stir for 20 minutes (stirrer speed 80r / min). The reacted material is sheared and emulsified by a nano-emulsifier (rotating speed 2880r / min), and then mixed by a high-energy static mixer for 1.2 hours. After treatment, it can be prepared into high-clean methanol diesel, and the particle diameter of the product is between 0.5nm and 10nm...

Embodiment 2

[0017] National standard diesel 55wt%, methanol 20wt%, co-solvent 20wt%, methyl tert-butyl ether 3wt%, ethyl nitrate 2wt%. Among them, the preparation ratio of methanol diesel co-solvent: vegetable oleic acid 30wt%, fatty acid methyl ester 20wt%, formaldehyde fat 10wt%, cyclohexylamine 10wt%, aviation kerosene 30wt%.

Embodiment 3

[0019] National standard diesel 50wt%, methanol 30wt%, co-solvent 16wt%, methyl tert-butyl ether 2wt%, ethyl nitrate 2wt%. Among them, the preparation ratio of methanol diesel co-solvent: vegetable oleic acid 40wt%, fatty acid methyl ester 20wt%, formaldehyde fat 9wt%, cyclohexylamine 10wt%, aviation kerosene 21wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com