Fluorine-containing acrylate leveling agent for solvent type coating

An acrylate, solvent-based technology, applied in the coating and other directions, can solve the problems of high surface tension, poor long-wave leveling, poor anti-shrinkage ability, etc., and achieve the effect of simple production method and excellent work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In a four-neck flask with a reflux condenser, a thermometer, a stirrer and a dropping funnel, add 70 grams of butyl acetate and start the stirrer to stir. When the temperature rises to 118°C, after the solvent butyl acetate refluxes in the condenser tube, start to drop 70 grams of butyl acetate, 150 grams of dodecafluoroheptyl methacrylate, 210 grams of butyl acrylate, and 5.74 grams of azo Diisobutyronitrile, add dropwise after 2h, then keep the temperature at 118°C and continue to stir for 2h; add dropwise a mixture of 40g butyl acetate and 1.19g azobisisobutyronitrile for 10 minutes, then keep the temperature at 118°C Stirring was continued for 2h. After the heat preservation is over, adjust the solid content to 70±2%, take out the product, and seal the can for packaging.

[0016] Product performance: appearance: yellowish transparent liquid; solid content: 70±2%; surface tension: 24-26 dynes;

[0017] When the surface tension is 24-26 dynes, the leveling agent can...

Embodiment 2

[0019] The consumption of each component is:

[0020]

[0021] Wherein the solvent is xylene, butyl acetate, propylene glycol methyl ether or propylene glycol methyl ether acetate; the fluorine-containing acrylate monomer is trifluoroethyl acrylate, trifluoroethyl methacrylate, hexafluorobutyl acrylate, methyl Hexafluorobutyl acrylate, dodecafluoroheptyl acrylate or dodecafluoroheptyl methacrylate; acrylate monomers are methyl acrylate, ethyl acrylate, butyl acrylate or 2-ethylethyl acrylate; The agent is azobisisobutyronitrile or benzoyl peroxide.

[0022] The step-by-step usage ratio of above-mentioned same component is with embodiment 1. All the other are with embodiment 1.

[0023] The obtained leveling agent has a surface tension of 24-26 dynes, a number-average molecular weight of 2000-4500, a weight-average molecular weight of 5000-12000, and a polydispersity of 2.0-2.8.

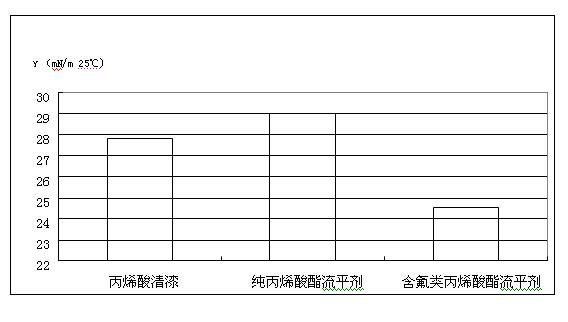

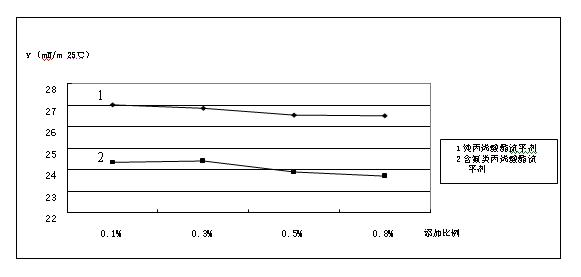

[0024] For example: 1. The surface tension value of fluorine-containing acrylate leveling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com