Capacitor bootstrap drive circuit and method of switched reluctance motor

A switched reluctance motor and drive circuit technology, which is applied in the direction of AC motor control, electrical components, electronic commutators, etc., can solve the problems of high circuit cost, large reference voltage, and failure to work normally and continuously, achieving strong practicability, The effect of simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

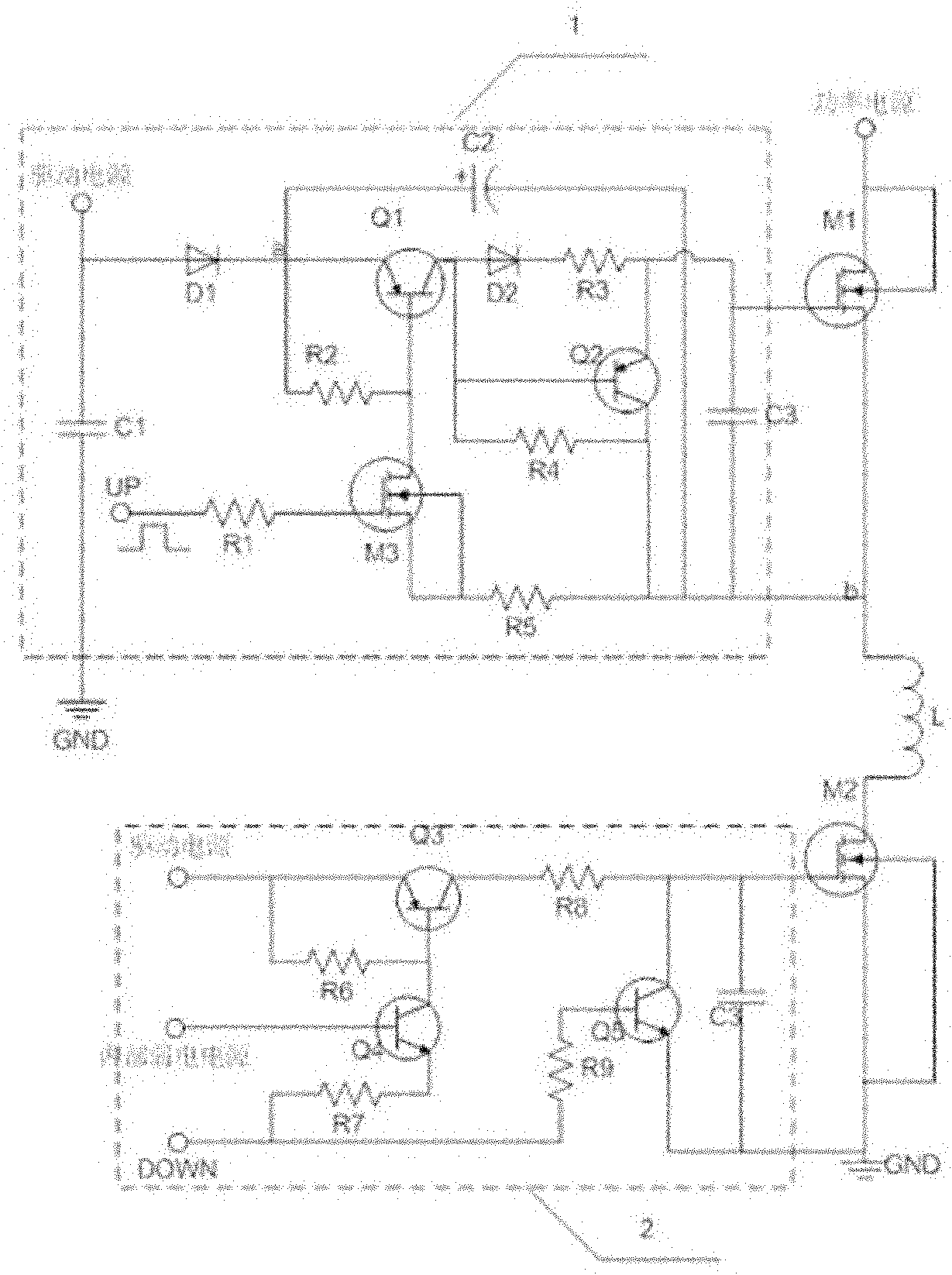

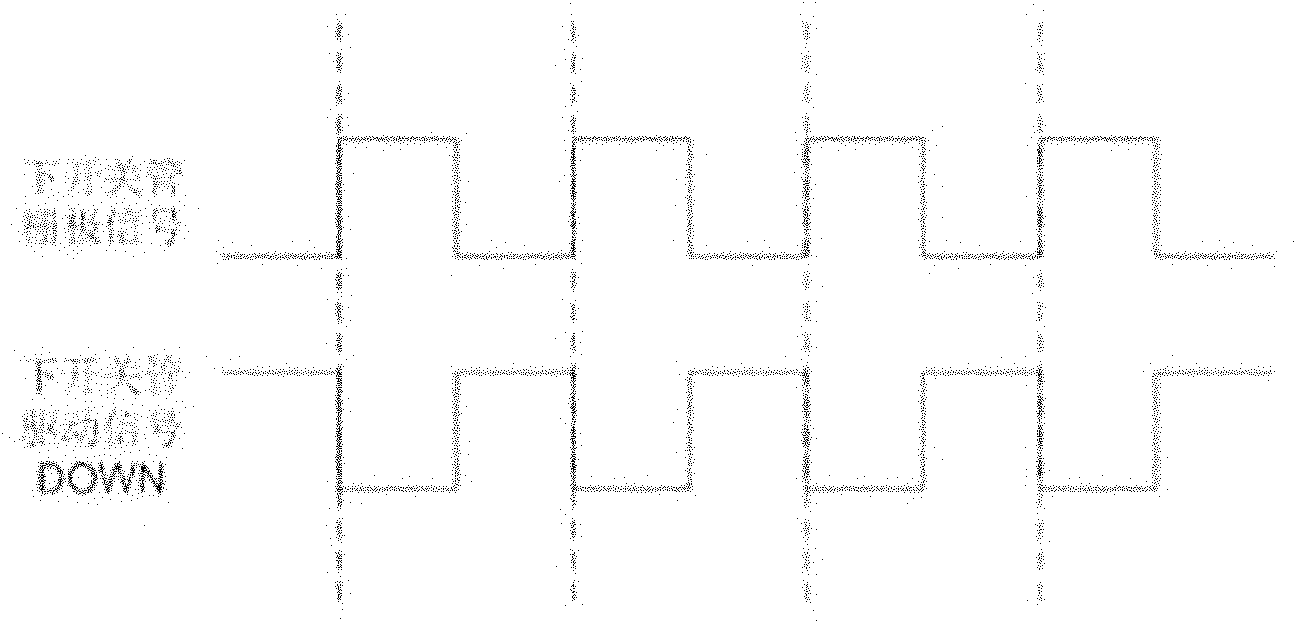

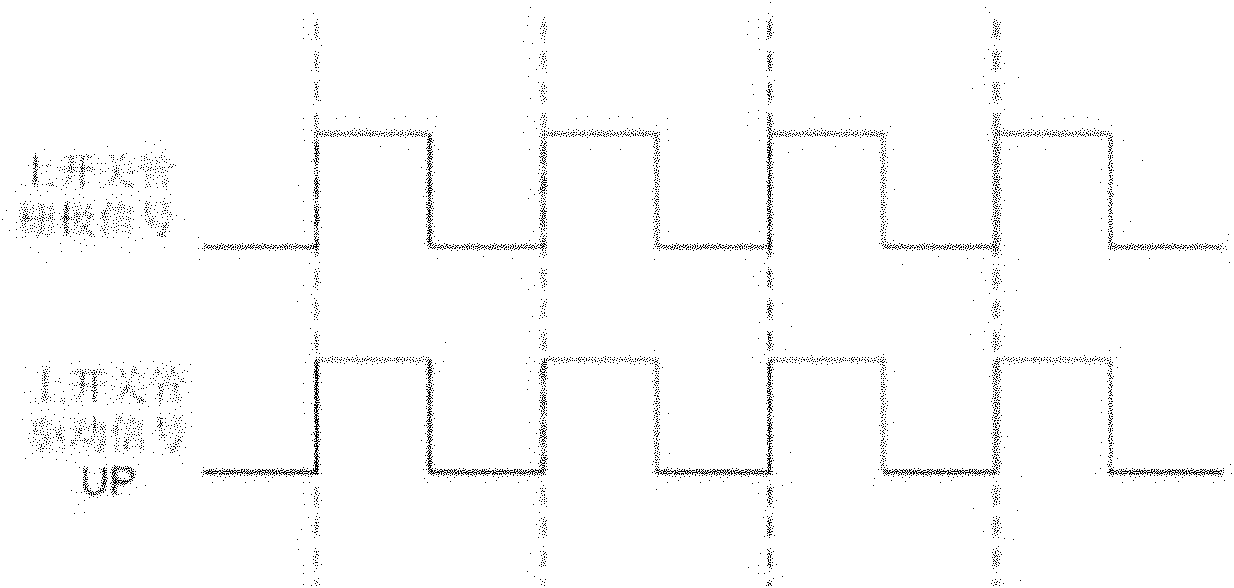

[0024] Such as figure 1 As shown, the upper switching tube driving circuit 1 receives the upper switching tube driving signal UP, and the lower switching tube driving circuit 2 receives the lower switching tube driving signal DOWN, respectively controlling the upper and lower switching tubes of the switched reluctance motor. The drive signal UP of the upper switch tube is connected to the first resistor R1, and the other end of the resistor is connected to the gate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com