Phosphorus-free precleaning prefilming agent and cleaning process

A chemical and pre-film technology, applied in the field of cleaning and pre-filming process, cleaning and pre-film water treatment chemicals, can solve problems such as excessive effluent, and achieve the effect of economical satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

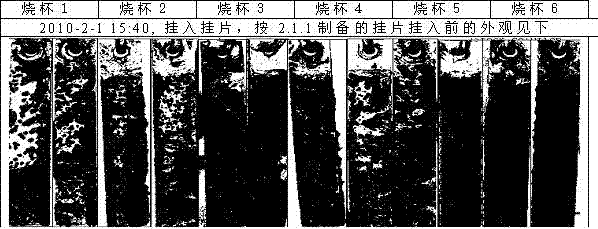

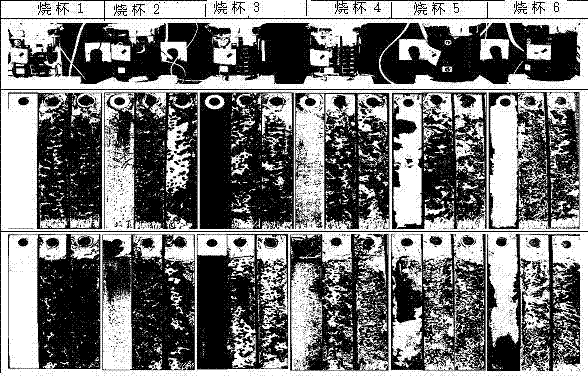

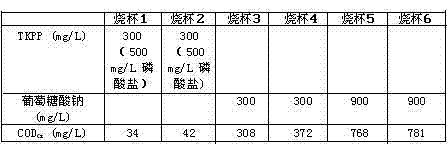

Image

Examples

Embodiment 1

[0028] Phosphate-free cleaning and pre-coating agents mainly include two components in independent packaging, in which component A is a phosphorus-free complexing agent, and component B is a phosphorus-free pickling agent. The weight of the two components A:B The serving ratio is 10-30:4-7.

[0029] Among them, the preparation of component A sodium gluconate adopts the heterogeneous catalytic oxidation method: prepare a certain amount of glucose solution and add it to a four-necked flask, weigh an appropriate amount of catalyst and add it to the flask, keep the temperature constant, feed air into the solution, and continuously A certain concentration of NaOH solution is added dropwise to maintain a certain pH value. After the reaction, the solution is cooled and filtered by suction (catalyst recovery), and the filtrate is concentrated and crystallized by distillation under reduced pressure to obtain sodium gluconate crystals after air-drying.

[0030] The preparation of compon...

Embodiment 2

[0077] The cleaning process using the phosphorus-free cleaning agent of the present invention: chemical cleaning mainly uses complexing agents, dispersants, pickling agents and bactericides to remove rust and dirt generated by the system during operation, and provide clean metal surfaces after cleaning , so that the protective film can be quickly established during pre-filming, and no phosphorus discharge can be achieved.

[0078] The main medicines and functions used in cleaning:

[0079] (1) Sodium gluconate: It is mainly a complexing agent, which has a good complexing effect on the rust in the system under certain pH conditions, so as to better remove the rust in the system. At the same time, it has a certain effect of corrosion inhibition and film formation, and has a certain protective effect on the cleaned surface.

[0080] (2) Dispersants: mainly polymer dispersants. It has a good dispersing effect on calcium phosphate, iron oxide, suspended solids, slime, etc.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com