Light-color antistatic coating with high electromagnetic wave transmissivity and preparation method thereof

An anti-static coating and electromagnetic wave technology, applied in the direction of conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of decreased wave transmittance, increased dielectric constant, poor aging resistance of paint films, etc., to achieve coating The effect of excellent film quality, low dielectric constant and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

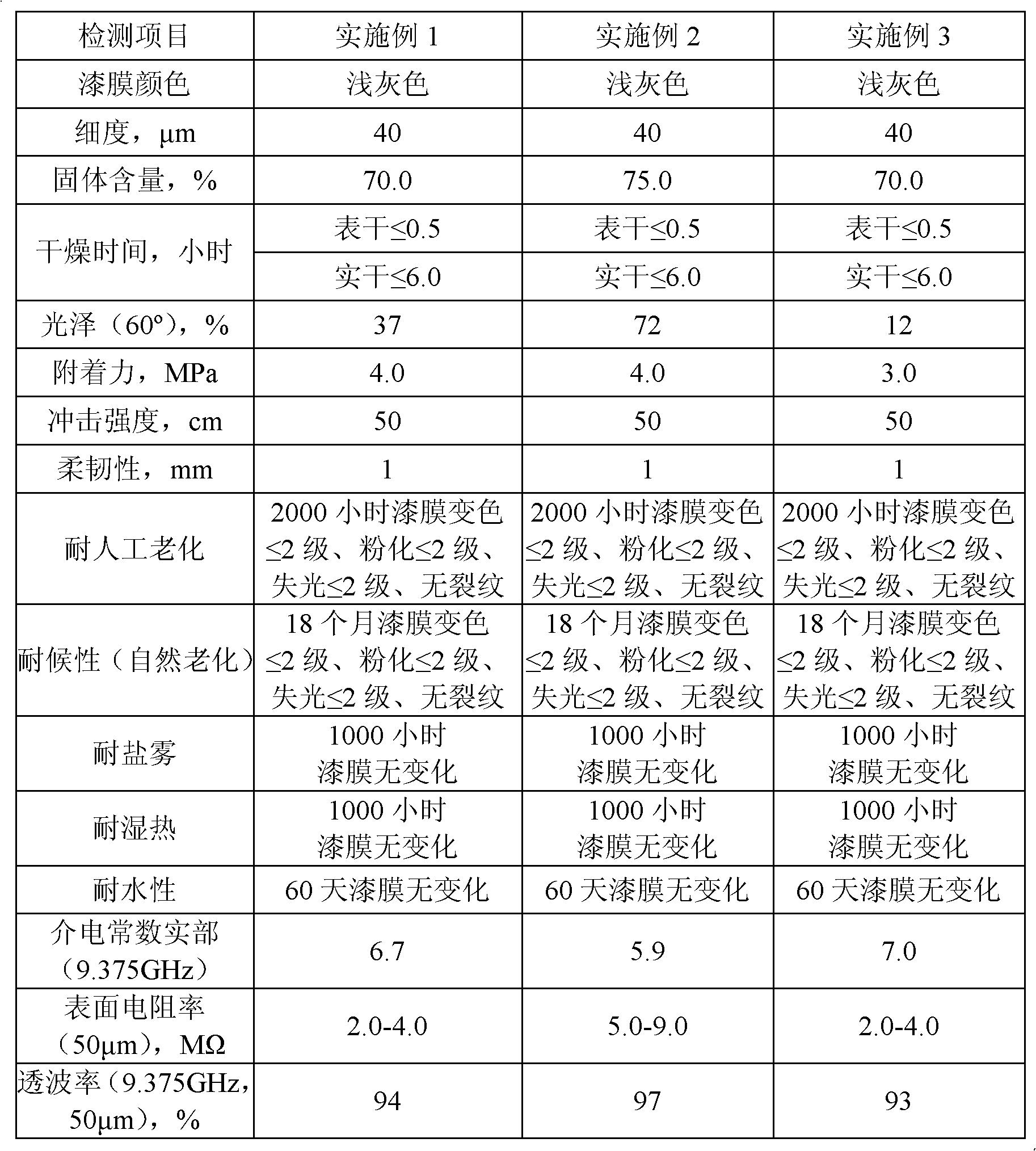

Examples

Embodiment 1

[0046] This embodiment provides a light-colored two-component antistatic coating with high electromagnetic wave transmittance, wherein, component A is mainly composed of hydroxyl fluorocarbon resin and composite conductive powder with a fluorine content of 35%, and has the following components Composition (unless otherwise stated, all ingredients are commercially available):

[0047] Hydroxyfluorocarbon resin (hydroxyl value 65mgKOH): 52 grams;

[0048] Mixed solvent (the weight ratio of xylene, butyl acetate, ethylene glycol ethyl ether acetate and propylene glycol methyl ether acetate is 1: 0.4: 0.2: 0.1): 15 grams;

[0049] Composite conductive powder (the weight ratio of conductive mica powder and conductive titanium dioxide is 1:0.5): 35 grams;

[0050] Dispersant (the molecular weight is the ethylene glycol ethyl ether acetate solution of the high molecular weight block copolymer containing amino group of 50000-80000, concentration is 45wt%): 0.1 gram;

[0051] Conduct...

Embodiment 2

[0059] This embodiment provides a light-colored two-component antistatic coating with high electromagnetic wave transmittance, wherein, component A is mainly composed of hydroxyfluorocarbon resin and composite conductive powder with a fluorine content of 24%, and has the following components Composition (unless otherwise stated, all ingredients are commercially available):

[0060] Hydroxyfluorocarbon resin (hydroxyl value 55mgKOH, solid fluorine content 24%): 65 grams;

[0061] Mixed solvent (the weight ratio of xylene, butyl acetate, ethylene glycol ethyl ether acetate and propylene glycol methyl ether acetate is 1: 0.4: 0.2: 0.1): 12 grams;

[0062] Composite conductive powder (the weight ratio of conductive mica powder and conductive titanium dioxide is 1:0.5): 35 grams;

[0063] Dispersant (ethylene glycol ether acetate solution of high molecular weight (molecular weight is 50000-80000) block copolymer containing amino group, concentration is 45wt%): 0.1 gram;

[0064] ...

Embodiment 3

[0072] This embodiment provides a light-colored two-component antistatic coating with high electromagnetic wave transmittance, wherein, component A is mainly composed of hydroxyl fluorocarbon resin and composite conductive powder with a fluorine content of 35%, and has the following components Composition (unless otherwise stated, all ingredients are commercially available):

[0073] Hydroxyfluorocarbon resin (hydroxyl value 65mgKOH, solid fluorine content 35%): 55 grams;

[0074] Mixed solvent (the weight ratio of xylene, butyl acetate, ethylene glycol ethyl ether acetate and propylene glycol methyl ether acetate is 1: 0.4: 0.2: 0.1): 16 grams;

[0075] Composite conductive powder (the weight ratio of conductive mica powder and conductive titanium dioxide is 1:0.8): 45 grams;

[0076] Dispersant (molecular weight is the ethylene glycol ethyl ether acetate solution of the high molecular weight block copolymer containing amino group of 50000-80000, concentration is 45wt%): 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com