Direct ink-jet printing disperse dye ink and use method thereof

A disperse dye and inkjet printing technology, applied in dyeing, ink, application, etc., can solve the problems of waste material generation and large consumption, and achieve the effect of high technical requirements and strong quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

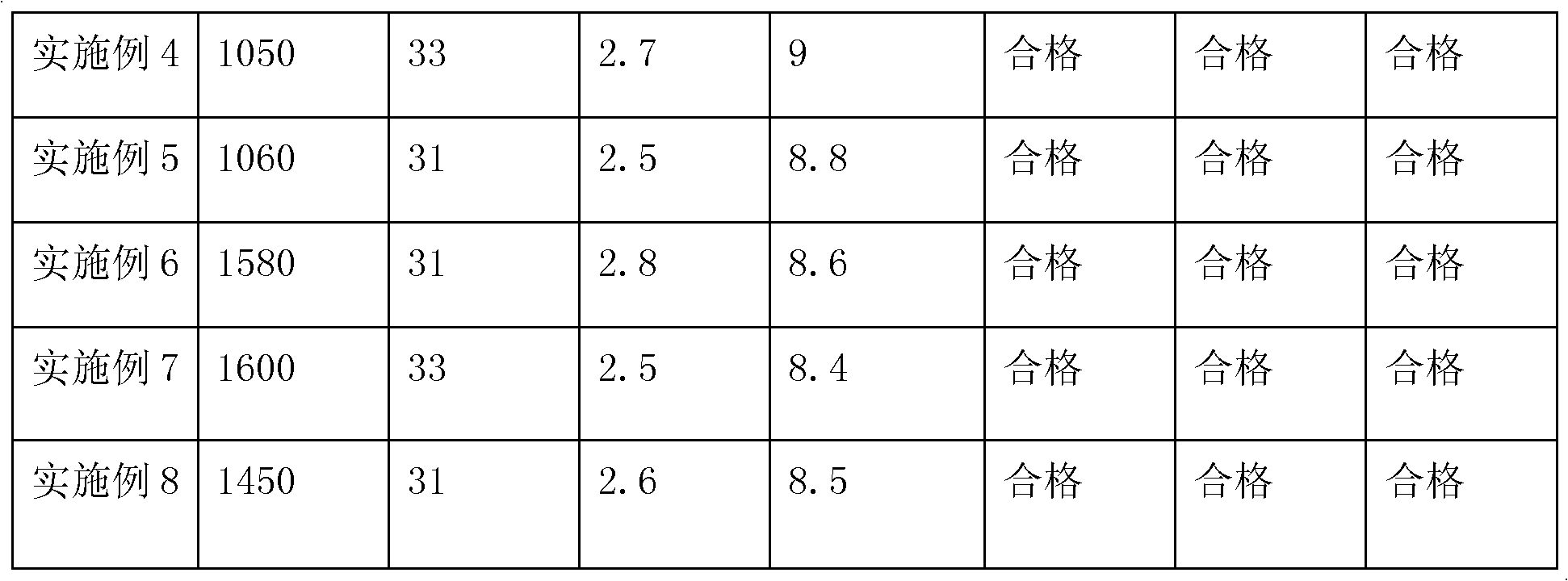

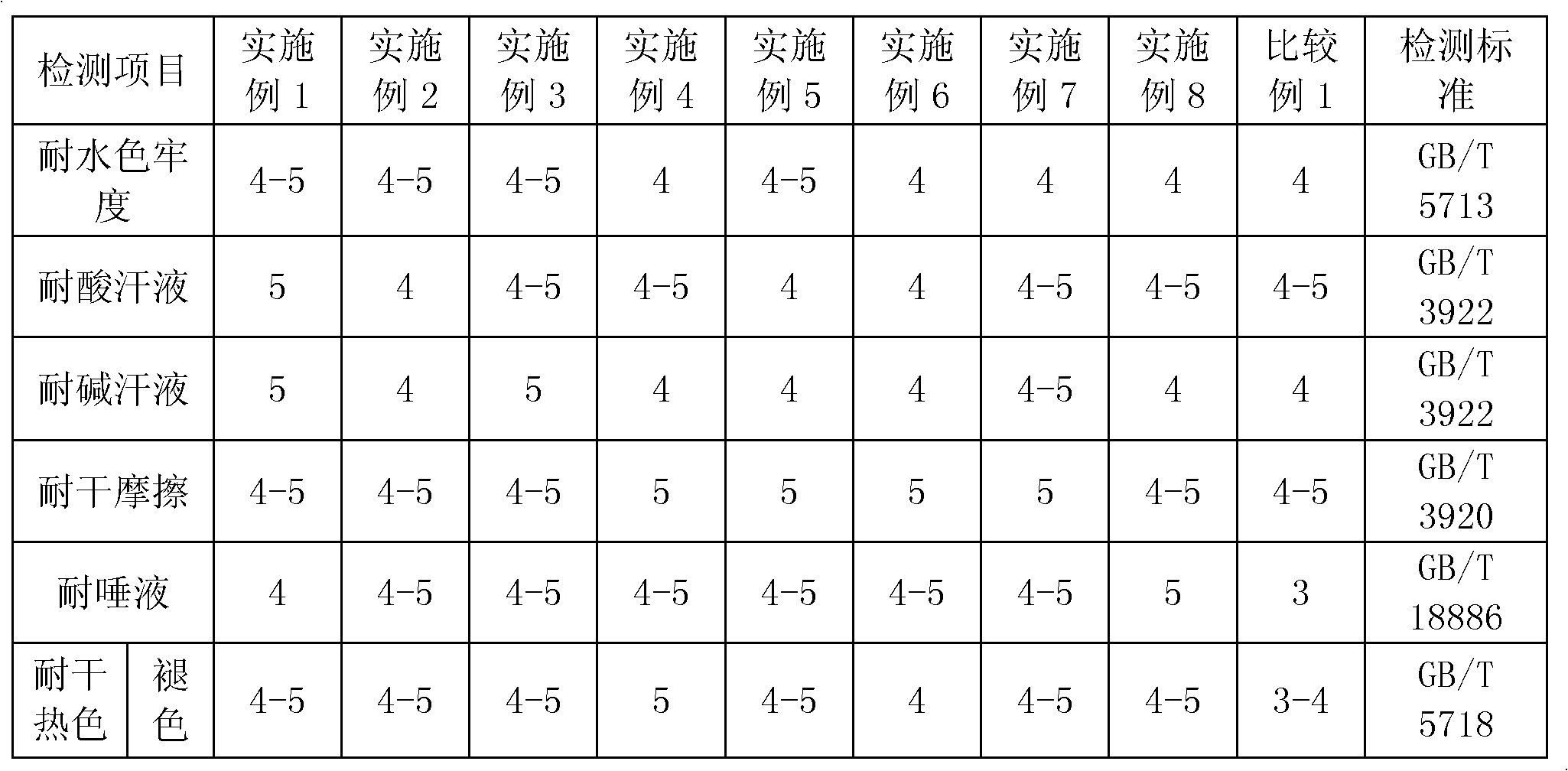

Examples

Embodiment 1

[0024] Disperse dye ink for direct inkjet printing, which consists of the following components by weight percentage: C.I. Disperse Blue 60 3%, C.I. Disperse Blue 93 6%, C.I. Disperse Orange 76 5%, BYK-2012 Dispersant 20%, Surfynol-465 Surface tension regulator 2%, 5-chloro-2-methyl-4-isothiazolin-3-one 1%, ethanol 2%, sodium hydroxide 0.1%, the rest is deionized water; After mixing evenly, the product can be obtained by filtering through a 0.45 micron filter membrane. In this embodiment, BYK-2012 dispersant produced by BYK Chemical Company and Surfynol-465 surface tension modifier produced by American Gas Chemical Company are preferred.

Embodiment 2

[0026] Direct inkjet printing disperse dye ink, which consists of the following components by weight percentage: C.I. disperse blue 284 8%, BYK-2012 dispersant 12%, Surfynol-465 surface tension regulator 1.2%, 5-chloro-2-formazine Diethyl-4-isothiazolin-3-one 0.5%, 1,5-pentanediol 5%, diethylene glycol 15%, triethanolamine 2%, the rest is deionized water; mix the above components in proportion Afterwards, the product can be obtained by filtering through a 0.45 micron filter membrane. In this embodiment, BYK-2012 dispersant produced by BYK Chemical Company and Surfynol-465 surface tension modifier produced by American Gas Chemical Company are preferred.

Embodiment 3

[0028] Disperse dye ink for direct inkjet printing, which consists of the following components by weight percentage: C.I. Base-4-isothiazolin-3-one 0.4%, triethylene glycol methyl ether 5%, tetraethylene glycol 10%, triethanolamine 1.0%, and the rest is deionized water; after mixing the above components in proportion The product can be obtained by filtering through a 0.45 micron membrane filter. In this embodiment, BYK-2012 dispersant produced by BYK Chemical Company and Surfynol-465 surface tension modifier produced by American Gas Chemical Company are preferred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com