Aqueous on-rust inorganic zinc-enriched coating and preparation method thereof

An inorganic zinc-rich coating and rust-bearing technology, applied in anti-corrosion coatings, alkali metal silicate coatings, etc., to achieve the effect of ensuring protection performance, good temperature resistance and fast self-drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

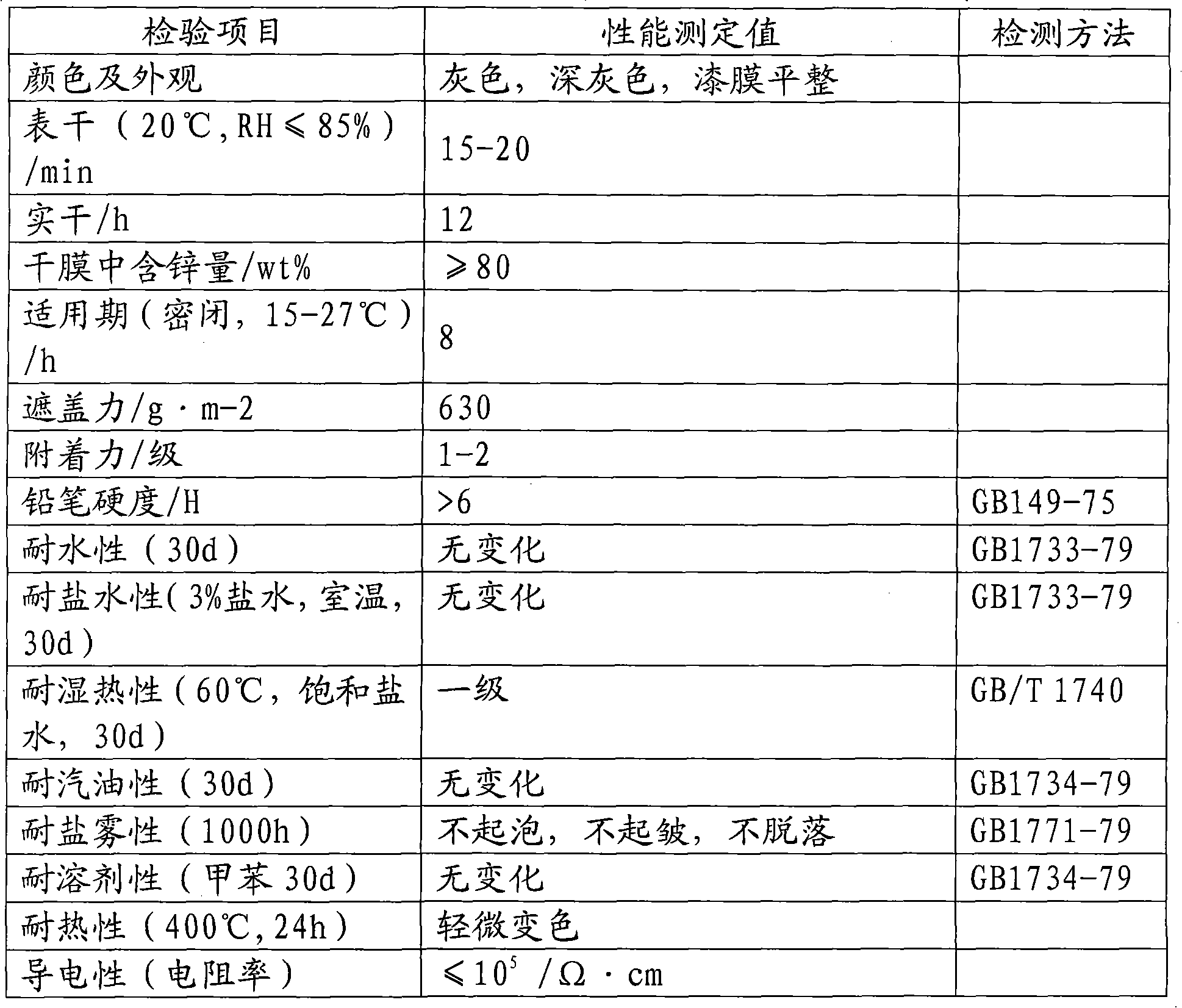

Examples

Embodiment 1

[0025] Add 10kg of lithium hydroxide for industrial use into 450kg of potassium silicate solution with a modulus of 3.2 and 350kg of deionized water under stirring, raise the temperature to 40-50°C, add 100kg of silica sol dropwise, keep warm for 30 minutes after completion, and then gradually add Petroleum sulfonate 10kg, acrylic acid emulsion 80kg, cooled and packed separately.

[0026] Mixing conditions: base material: powder = 1:2.5, slowly pour 500-600 mesh zinc powder into the base material, and keep stirring at the same time, fully mix the zinc powder in a suspended state, and sieve it with 60-100 mesh before spraying net filter.

[0027] Surface treatment: remove oil stains on the steel surface first, remove iron scale and rust by manual grinding, and use compressed air to completely remove impurities such as gravel and dust before brushing.

[0028] Construction Conditions:

[0029] (1) Apply by spraying or brushing, and the tools are clean and oil-free.

[0030] (...

Embodiment 2

[0035] Add 25kg of lithium hydroxide for industrial use into 550kg of potassium silicate solution with a modulus of 3.4 and 300kg of deionized water under stirring, raise the temperature to 40-50°C, add 40kg of silica sol dropwise, keep warm for 30 minutes after completion, and then gradually add Petroleum sulfonate 20kg, acrylic acid emulsion 65kg, cooled and packed separately.

[0036] Mixing conditions: base material: powder = 1:3, slowly pour 500-600 mesh zinc powder into the base material, and keep stirring at the same time, fully mix the zinc powder in a suspended state, and use a 60-100 mesh sieve before spraying net filter.

[0037] Construction Conditions:

[0038] (1) Apply by spraying or brushing, and the tools are clean and oil-free.

[0039] (2) The construction temperature is 5-50°C, and the relative humidity is below 85% (keep ventilation).

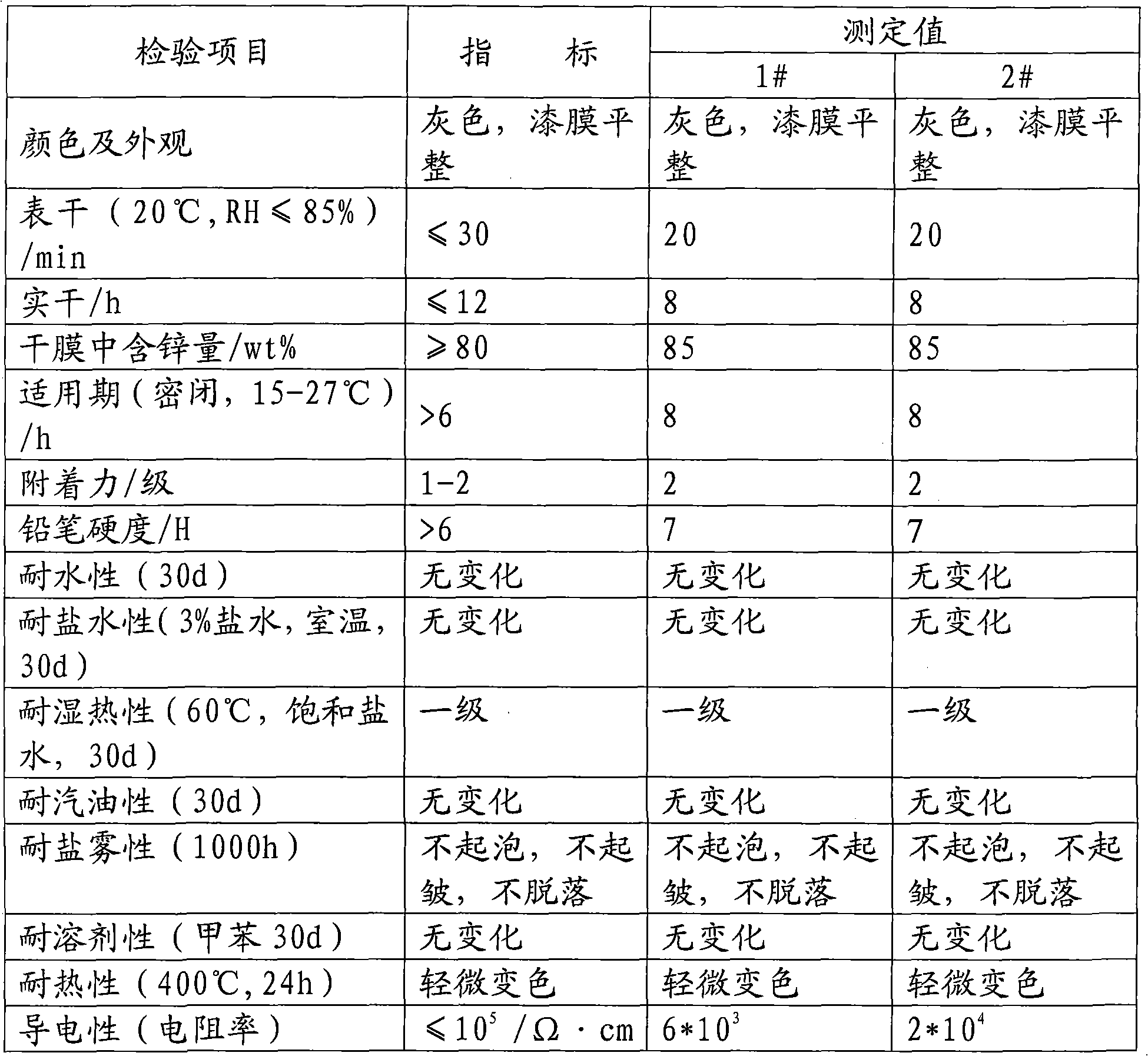

[0040] Comparative Experiment:

[0041] Take the 1# sample plate as 1mm thick 235 steel plate, polish it without rust...

Embodiment 3

[0047] Add 15kg of lithium hydroxide for industrial use into 600kg of potassium silicate solution with a modulus of 3.8 and 240kg of deionized water under stirring, raise the temperature to 40-50°C, add 60kg of silica sol dropwise, keep warm for 30 minutes after completion, and then gradually add Petroleum sulfonate 30kg, acrylic acid emulsion 55kg, cooled and packed separately.

[0048] Mixing conditions: base material: powder = 1:2.5, slowly pour 500-600 mesh zinc powder into the base material, and keep stirring at the same time, fully mix the zinc powder in a suspended state, and sieve it with 60-100 mesh before spraying net filter.

[0049] Construction Conditions:

[0050] (1) Apply by spraying or brushing, and the tools are clean and oil-free.

[0051] (2) The construction temperature is 5-50°C, and the relative humidity is below 85% (keep ventilation).

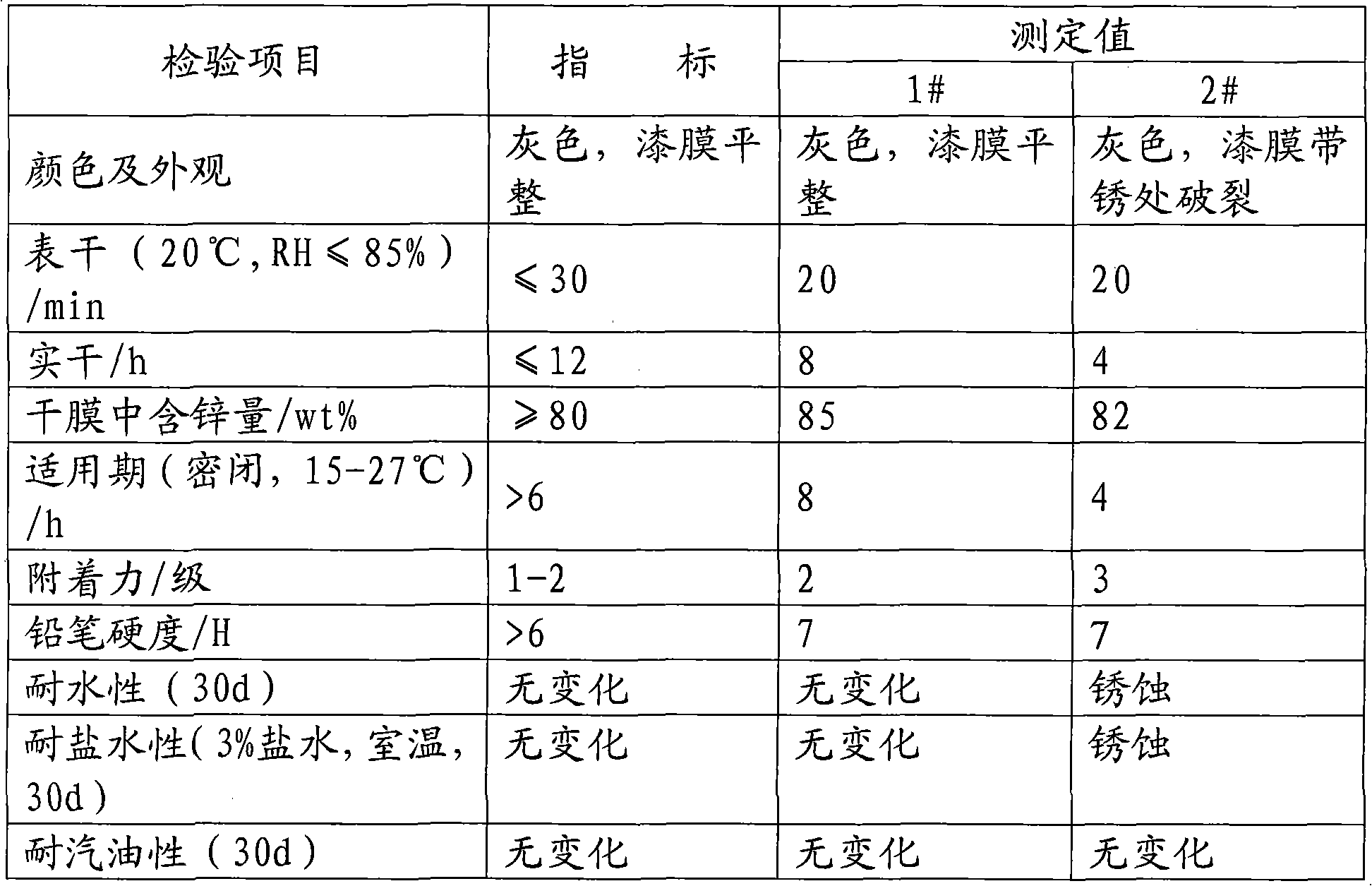

[0052] Comparative Experiment:

[0053] Take the 1# sample plate as 1mm thick 235 steel plate, polish it with rus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com