Dry material and method for building ladle lining by using same

A dry material and tundish technology, applied in the field of refractory materials, can solve the problems of inability to purify molten steel and high cost of raw materials, and achieve the effects of being easy to turn over, good integrity, and avoiding hydration reactions.

Active Publication Date: 2013-03-27

KUNMING IRON & STEEL GRP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for areas without magnesia resources, magnesia for the production of magnesia dry materials needs to be purchased from afar, not only the cost of raw materials is high, but also the molten steel cannot be purified

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

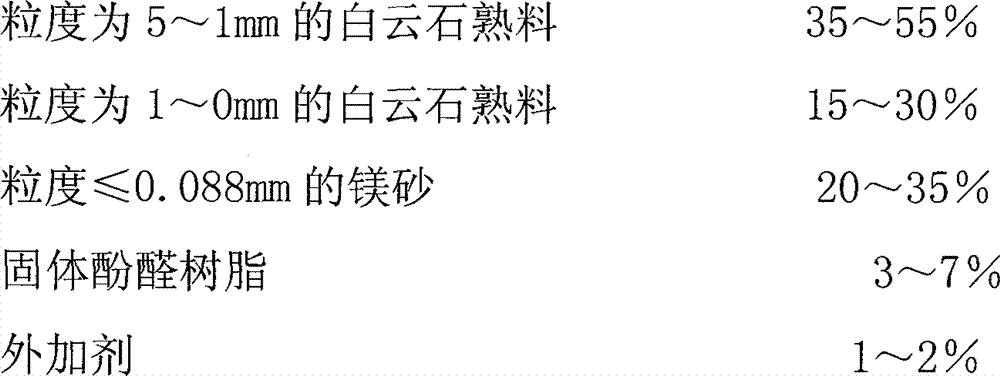

[0023] Mix the raw materials into a dry formula according to the following formula:

[0024]

Embodiment 2

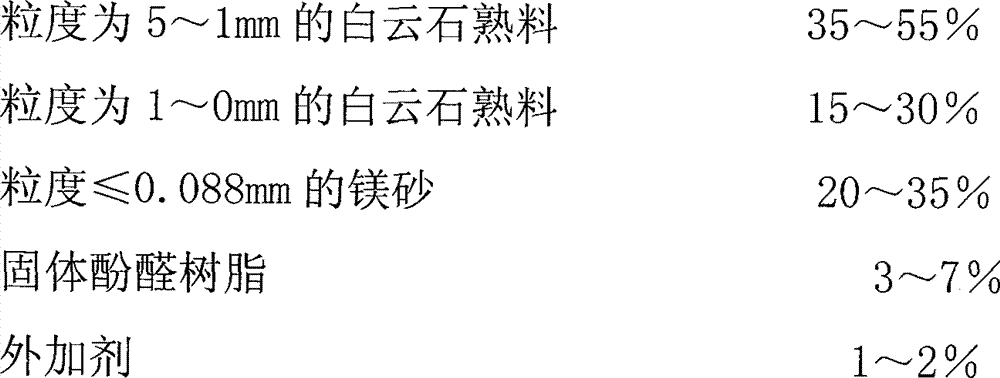

[0026] Mix the raw materials into a dry formula according to the following formula:

[0027]

Embodiment 3

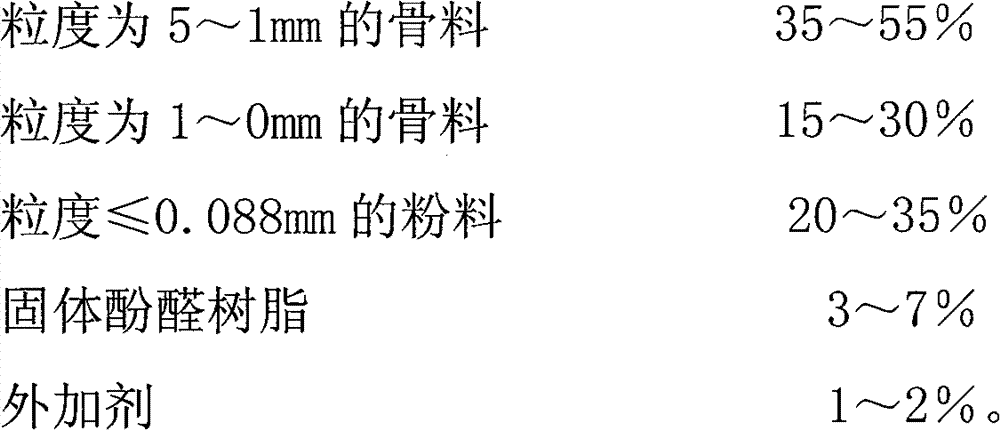

[0029] Mix the raw materials into a dry formula according to the following formula:

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a dry material and a method for building a ladle lining by using the same. The dry material consists of the following raw materials in percentage by mass: 35-55 percent of aggregate with the particle size of between 5 millimeters and 1 millimeter, 15-30 percent of aggregate with the particle size of between 0 millimeter and 1 millimeter, 20-35 percent of powder with the particle size of less than or equal to 0.088 millimeters, 3-7 percent of solid phenolic resin and 1-2 percent of additive. In the method, dolomite serving as a rich resource can be fully utilized and calcined into clinker dolomite, and calcium in the clinker dolomite is directly added in the form of calcium oxide. When the calcium oxide with molten steel cleaning function is applied to a tundish lining, the deposition of aluminum oxide in the tundish can be reduced, phosphor removal and sulfur removal are performed, and inclusions in molten steel are reduced. Meanwhile, hydration-proof treatment is performed on the surface of the constructed tundish lining, so that the dry material is effectively isolated from the air, hydration reaction of the clinker dolomite caused by absorption of moisture in the air is avoided, the clinker dolomite has high integrity and is resistant to flushing and erosion of molten steel and slag liquid in a using process, the clinker dolomite is easily separated from a flame retardant coating and is convenient to overturn after being used, and sequential casting is over 30 hours.

Description

technical field [0001] The invention relates to a dry-type material, in particular to a dry-type refractory material used as a ladle lining, and belongs to the technical field of refractory materials. Background technique [0002] With the continuous improvement of the continuous casting level of continuous casting production in my country, the working life of the working lining of the continuous casting tundish has been greatly extended, and has developed from the original 5 hours to more than 30 hours today. Materials present even more stringent requirements. The material used in the tundish is a new scientific and technological achievement, which is suitable for the working layer of the tundish. It is a new type of unshaped refractory material for the working layer of the tundish following the insulation board of the tundish and the smearing material (spray paint) of the tundish. It is the same as The biggest difference between the commonly used wet paint (spray paint) is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/66B22D41/02

Inventor 赵利明杨增福鲁志燕孔光云

Owner KUNMING IRON & STEEL GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com