Method for building greenhouse for cultivating mushrooms

A technology for a greenhouse and a construction method is applied in the field of construction of a greenhouse for cultivating shiitake mushrooms, and can solve the problems of affecting the speed of popularization and production efficiency of shiitake mushrooms, the high price of thermal insulation materials, poor use effect, and the like, so as to improve land utilization and thermal insulation performance. Good, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

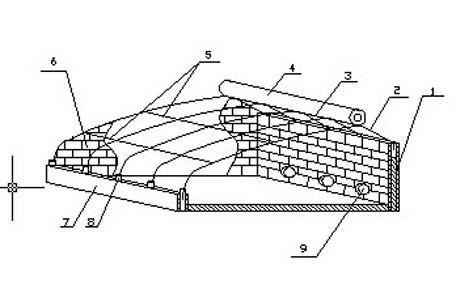

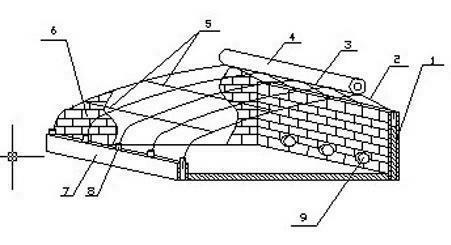

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] see figure 1 , the construction method of this shiitake mushroom cultivation greenhouse of the present invention, carries out as follows:

[0024] ⑴First determine the shed: the shed should be leeward to the sun, with good drainage performance and no pollution sources around, and the construction orientation is 5° overcast.

[0025] ⑵Determine the construction size: ①The width of the shed is 1050cm, the length is not limited, and the ratio of ridge height to width is 1: 2.5; Every 3.5m of the wall is connected with piles, and the upper edge is left, and two brick-thick arch sockets are left every 90cm at the edge; ③The thickness of the gable wall 6 is the same as that of the rear wall 1, and a solid wall is built, which is in the shape of a front slope.

[0026] (3) Ventilation holes 9 are set on the back wall 1: Leave a ventilation hole 9 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com