Compound control method based on vector control system of permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and compound control, which is applied in the direction of vector control system, control system, motor generator control, etc., can solve the problems of rapidity and limited anti-interference, and achieve widening of control range, good control effect, and high-efficiency data The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

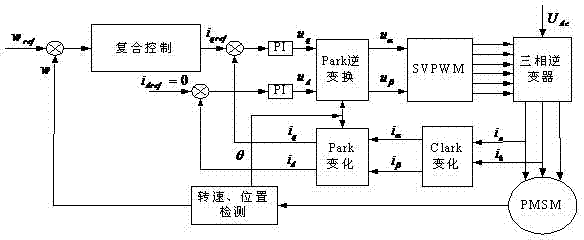

[0023] The functional block diagram of the compound control method of the opportunity permanent magnet synchronous motor vector control system described in this embodiment is as follows figure 1 As shown, firstly, each physical quantity is converted from the stationary coordinate system (three-phase stator coordinate system) to the synchronous rotating coordinate system (d, q coordinate system) by means of Clark transformation and Park transformation. This embodiment actually detects the two-phase current i a i b , through the Clark transformation, get i α i β , and then obtain the direct axis current i in the rotating coordinate system through Park transformation d and quadrature current i q As the current feedback value of the current loop for feedback comparison, while using i d The method of =0 further linearly decouples the mathematical model on the d and q axes of the permanent magnet synchronous motor. The direct axis and quadrature axis currents are compared by fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com