Plate-type pulsating heat pipe with double-side grooves

A pulsating heat pipe and double-sided groove technology, which is applied in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems such as the lack of a unified explanation for the pulsating heat transfer mechanism and the insufficient attention to the application of pulsating heat pipes. Achieve the effect of improving the internal working medium distribution and heat transfer uniformity, good heat transfer capacity, and convenient vacuuming and filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

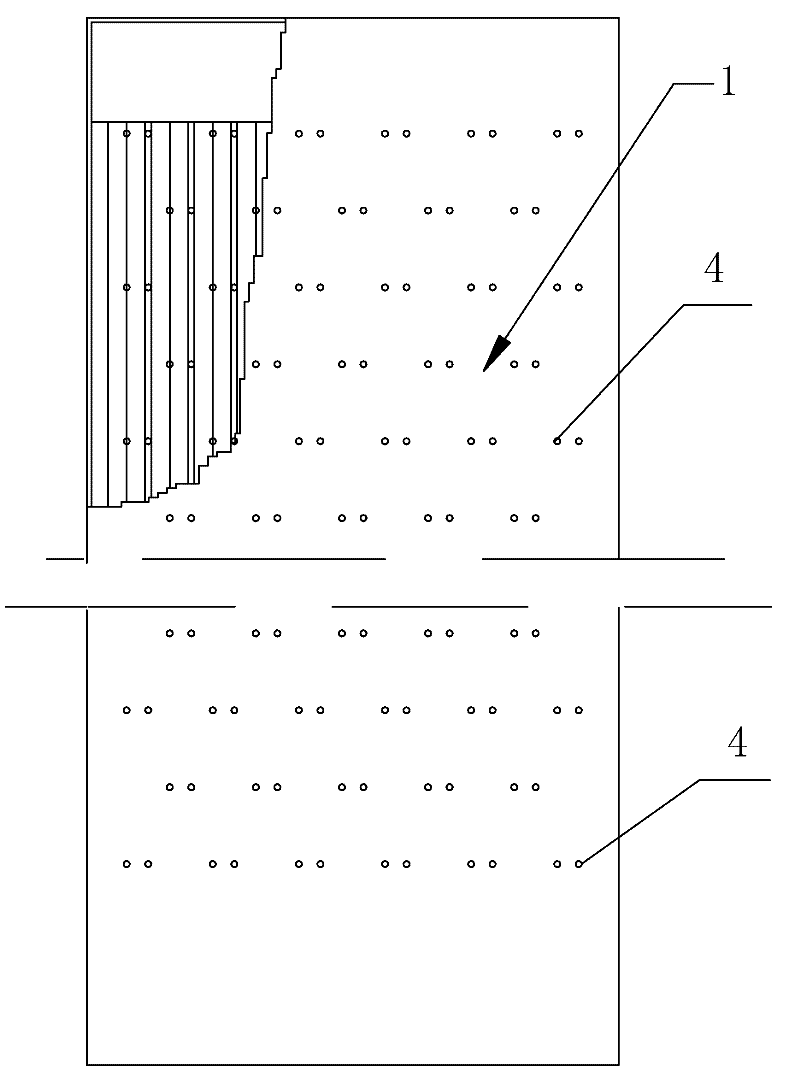

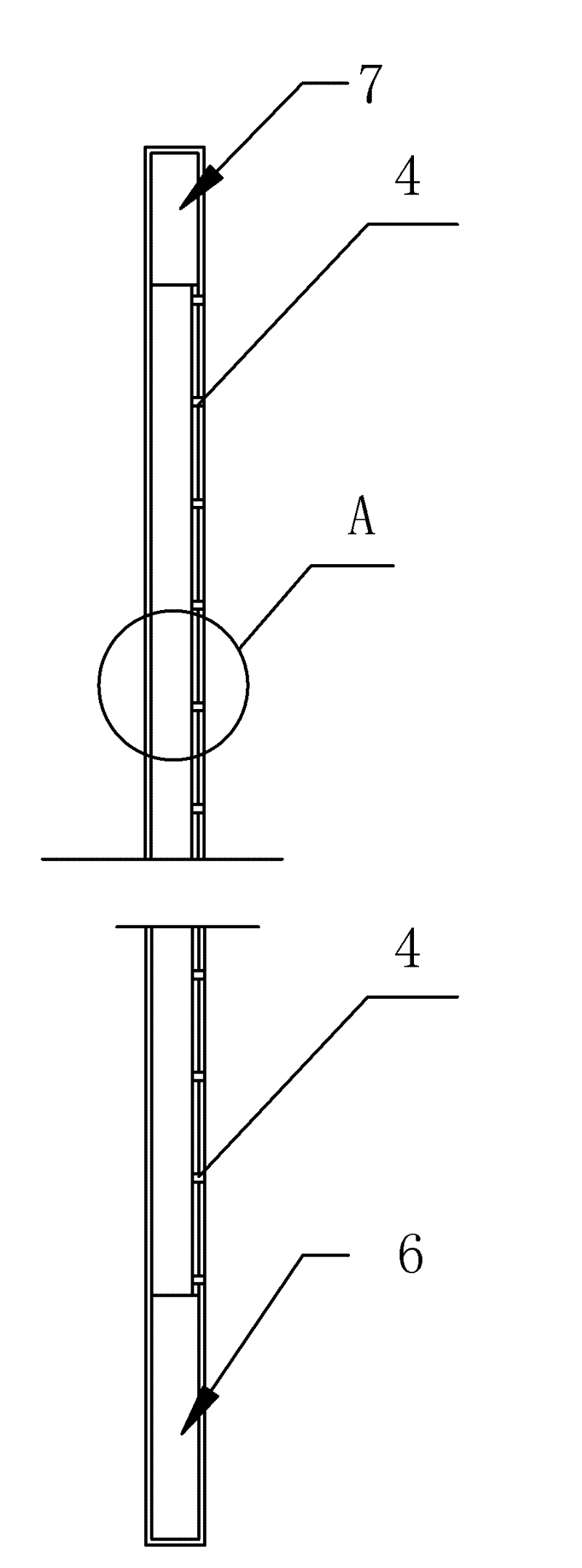

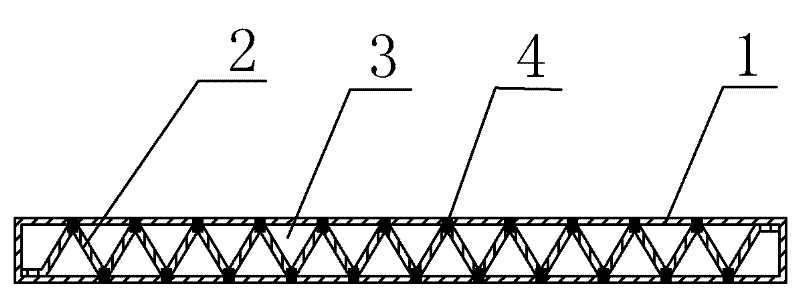

[0048] See attached figure 1 , 2 , 3, 4, the double-sided channel plate-type pulsating heat pipe of the present invention includes a shell 1, a folded plate 2. The cross section of the shell 1 is a rectangular closed box; the folded plate 2 is composed of a periodic triangular shape The folded plate 2 is inserted into the housing 1, so that a plurality of pulsating channels 3 are formed between the folded plate 2 and the inner surface of the housing 1; The ribs are connected to the inner surface of the shell 1 by discontinuous spot welding joints 4, so that a micro seam 5 is formed between adjacent channels; the shell 1 is closed, evacuated, and filled with distilled water as a working substance; The folded plate 2 is not flush with the ends 6 and 7 of the shell 1; the equivalent diameter of the pulsating channel 3 is 0.5-1mm; the shell and the folded plate are made of stainless steel; The length is 5-50mm, and the width of the micro slit 5 is 3-30μm.

[0049] The maximum equiva...

Embodiment 2

[0051] See attached Figure 5 , 6 , The double-sided channel plate type pulsating heat pipe of the present invention includes a shell 1, a folded plate 2, the cross section of the shell 1 is a rectangular closed box; the folded plate 2 is a curved panel composed of a periodic sine wave shape , The shell 1 and the folded plate 2 are integrally stretched or integrally extruded, the folded plate 2 is in the shell 1, and the inner surface of the folded plate 2 and the shell 1 A number of pulsating channels 3 are formed between; the shell 1 is closed, evacuated and filled with working medium R123; the folded plate 2 is not flush with the end of the shell 1; the equivalent diameter of the channel is 0.5~3.5mm; The shell and the folded plate are made of aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com