Independent solar direct thermal drive using mixed working fluid to remove CO 2 system

A mixed working fluid and thermally driven technology, applied in the field of CO2 removal systems with mixed working fluids, can solve the problems of low energy consumption for regeneration and large energy consumption for regeneration, and achieve the effects of improving life expectancy, compact system and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

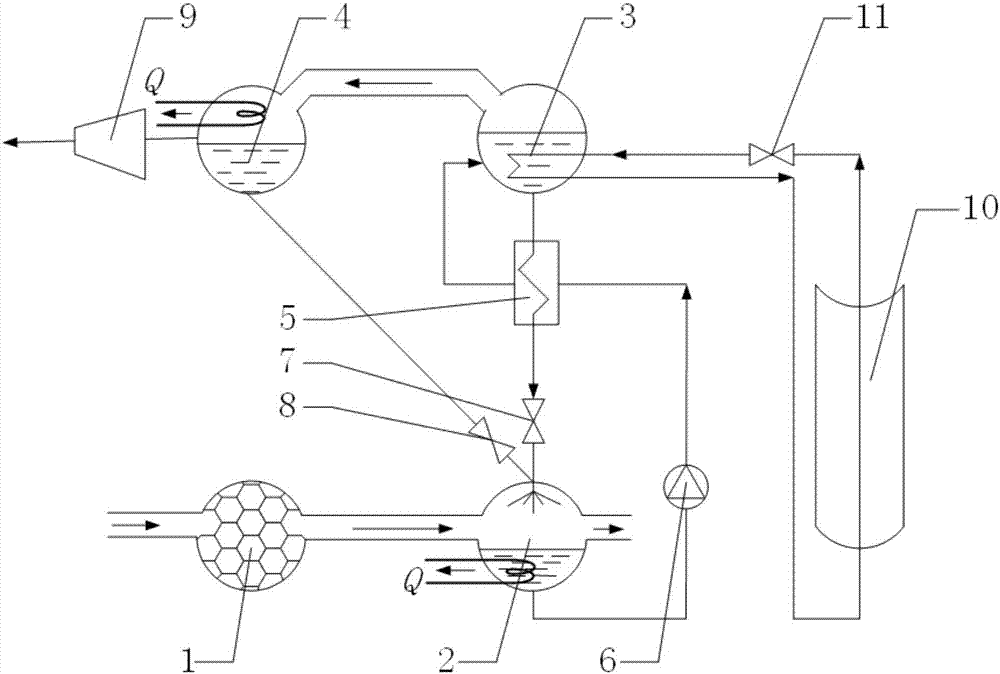

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0023] The present invention utilizes the mixed working medium at different temperatures of CO 2The difference in loading realizes the removal of carbon dioxide from the flue gas, and the heat exchange between the high-temperature regeneration absorption working fluid and the low-temperature absorption mixed solution is realized inside the system to improve the utilization rate of heat; the infusion pump and the conventional system are replaced by throttle valves. The recooler saves energy and makes the system more compact; uses solar heat collection as heat-driven energy, makes full use of the advantages of solar energy regeneration, realizes the purpose of energy saving a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com