Lignite drying, sloshing dust-removing and washing process

A drying and technological technology, applied in the direction of drying solid materials, non-progressive dryer, heating to dry solid materials, etc., to achieve the effect of preventing thermal decomposition, shallow buried layer and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

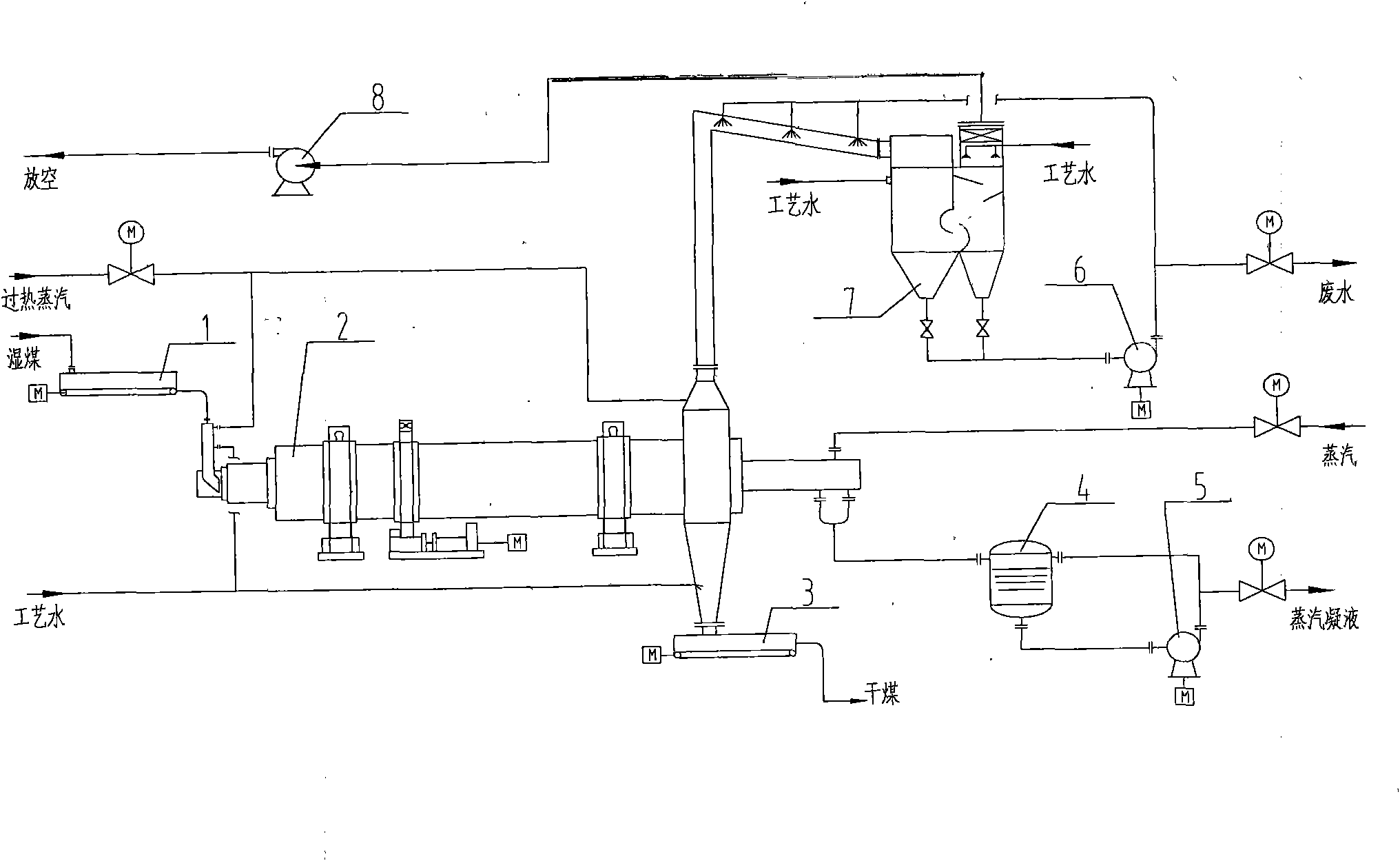

[0026] Below, the present invention is described further with reference to accompanying drawing:

[0027] The wet coal powder enters the steam pipe rotary dryer 2 through the feeding belt 1 for drying. The water vapor used for drying enters from the rotary joint at the discharge end of the dryer, and enters the heat exchange tube through the steam chamber. The wet pulverized coal is in contact with the steam pipe for heat exchange, and the moisture in it is continuously evaporated. The dried product is discharged from the discharge port and transported to the next section through the discharge belt 3. The condensed water generated by steam heat exchange enters the condensate tank 4 through the rotary joint, and then is transported to the next section by the condensate pump 5 . The tail gas produced in the drying process is firstly dedusted in the discharge box (gravity settling chamber) at the tail of the dryer, then discharged from the top of the discharge box, and then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com