Equipment and method for treating ship domestic sewage through electrolytic process

A technology of domestic sewage and electrolysis, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , Water quality adaptability, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

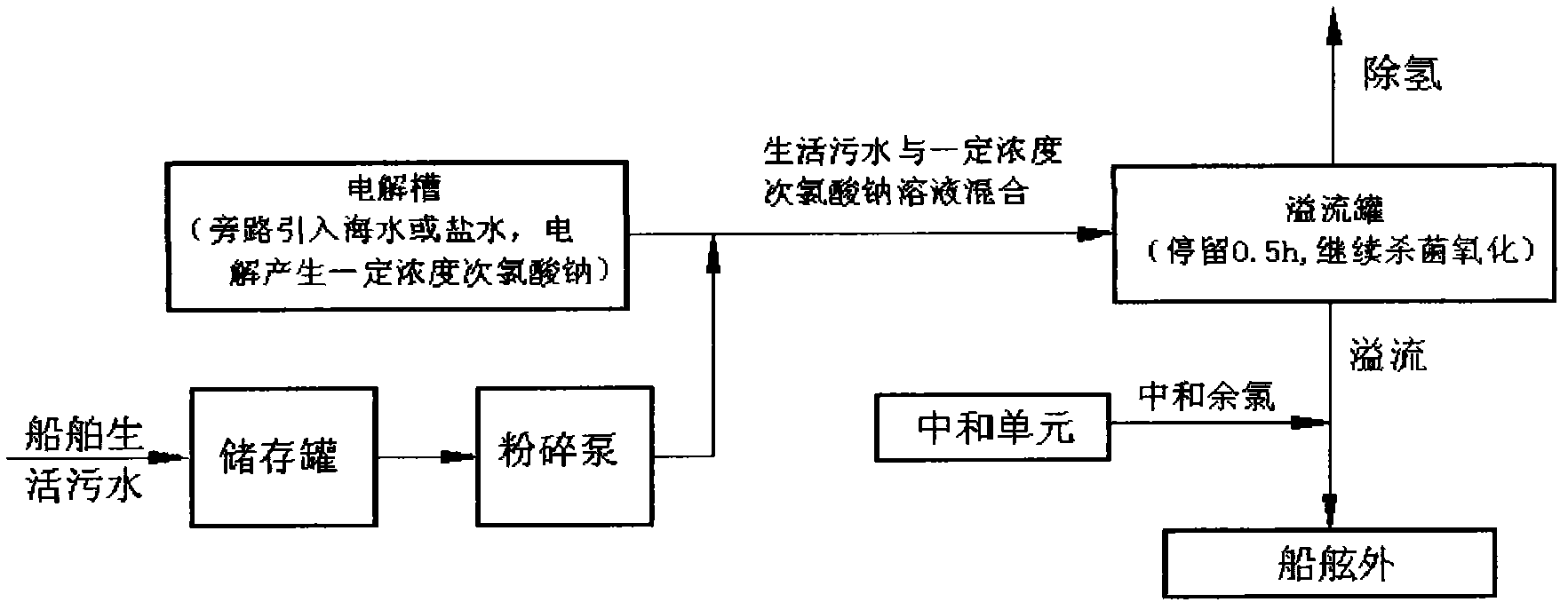

Method used

Image

Examples

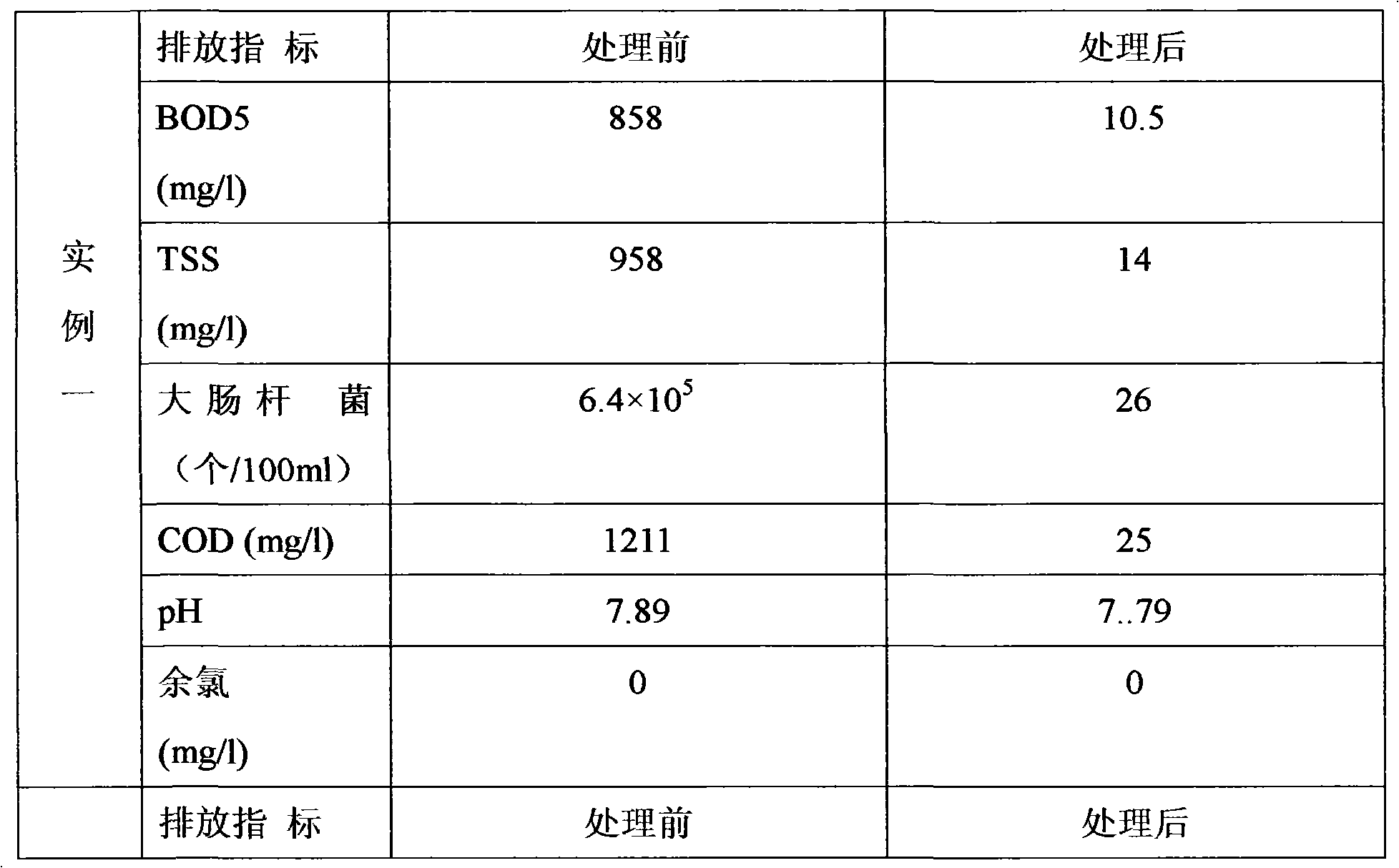

example 1

[0064]Example 1: First use a crushing pump to crush the larger solid particles in the domestic sewage, lead a road of seawater through the electrolytic cell, and electrolyze to produce a certain concentration of sodium hypochlorite seawater solution. Inject the pulverized ship domestic sewage into the pipeline of a certain concentration of sodium hypochlorite seawater solution produced by electrolysis. After measurement, the concentration of sodium hypochlorite in the mixed ship domestic sewage is 30ppm. After mixing, the domestic sewage containing 30ppm sodium hypochlorite stays in the overflow tank for 30 minutes to sterilize and oxidize and decompose part of the sodium hypochlorite. After the domestic sewage flows out of the overflow tank, the neutralization unit is used to eliminate residual chlorine, and then discharged.

example 2

[0065] Example 2: First use a crushing pump to crush the larger solid particles in the domestic sewage, lead a road of seawater through the electrolytic cell, and electrolyze to produce a certain concentration of sodium hypochlorite seawater solution. Inject the pulverized ship domestic sewage into the pipeline of a certain concentration of sodium hypochlorite seawater solution produced by electrolysis. After measurement, the concentration of sodium hypochlorite in the mixed ship domestic sewage is 5 ppm. After mixing, the domestic sewage containing 5ppm sodium hypochlorite stays in the overflow tank for 30 minutes to sterilize and oxidize and decompose part of the sodium hypochlorite. After the domestic sewage flows out of the overflow tank, the neutralization unit is used to eliminate residual chlorine, and then discharged.

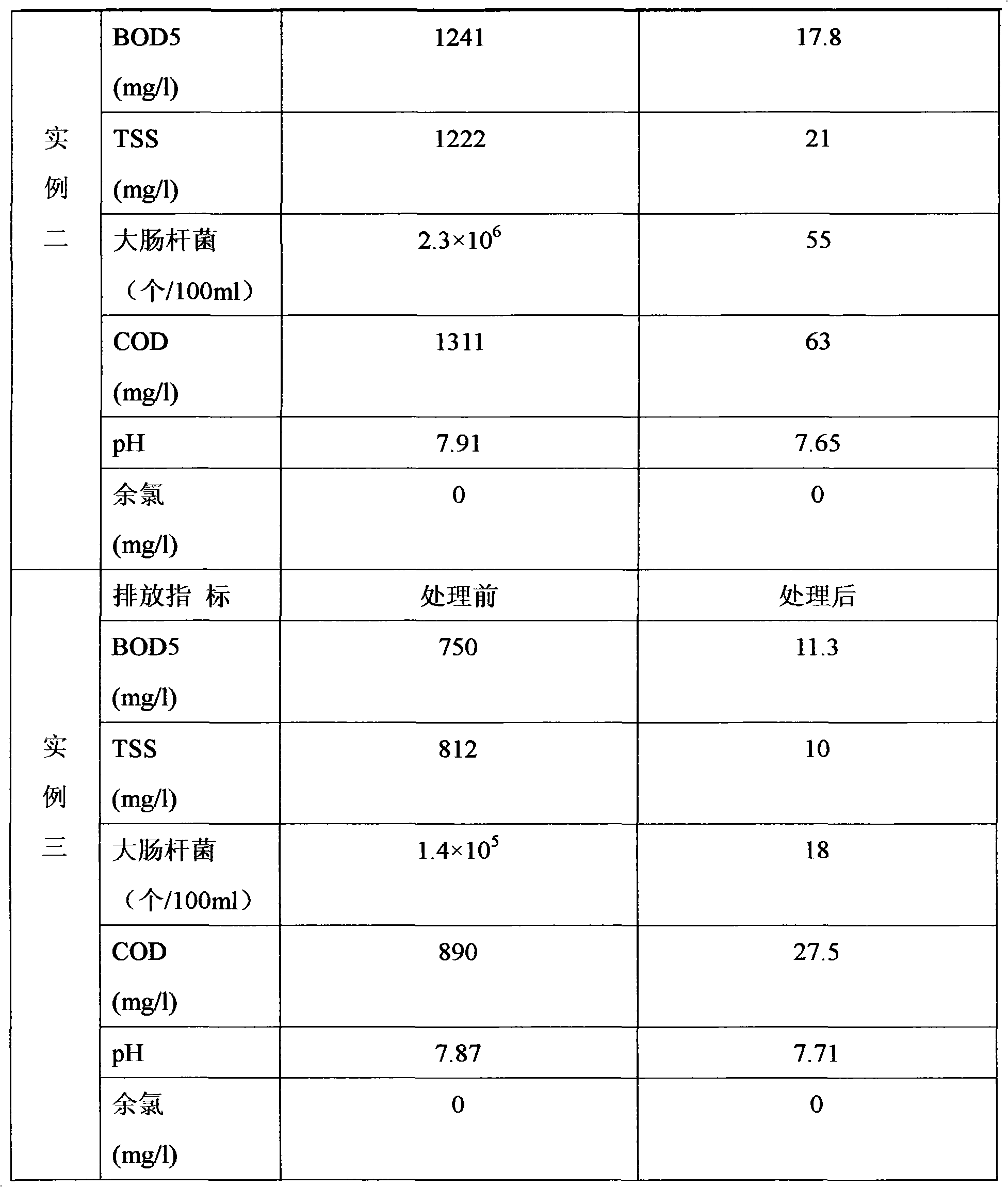

example 3

[0066] Example 3: First use a crushing pump to crush the larger solid particles in the domestic sewage, lead a road of seawater through the electrolytic cell, and electrolyze to produce a certain concentration of sodium hypochlorite seawater solution. Inject the pulverized ship domestic sewage into the pipeline of a certain concentration of sodium hypochlorite seawater solution produced by electrolysis. After measurement, the concentration of sodium hypochlorite in the mixed ship domestic sewage is 20ppm. After mixing, the domestic sewage containing 20ppm sodium hypochlorite stays in the overflow tank for 30 minutes to sterilize and oxidize and decompose part of the sodium hypochlorite. After the domestic sewage flows out of the overflow tank, the neutralization unit is used to eliminate residual chlorine, and then discharged.

[0067] Table-2 The effect of ship sewage treatment in the embodiment

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com