Expanded bed chromatographic separation device for biochemical separation technology

A separation technology, a chromatographic separation technology, is applied in the field of chromatographic separation devices to achieve the effects of easy control, increasing the number of theoretical plates for separation, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

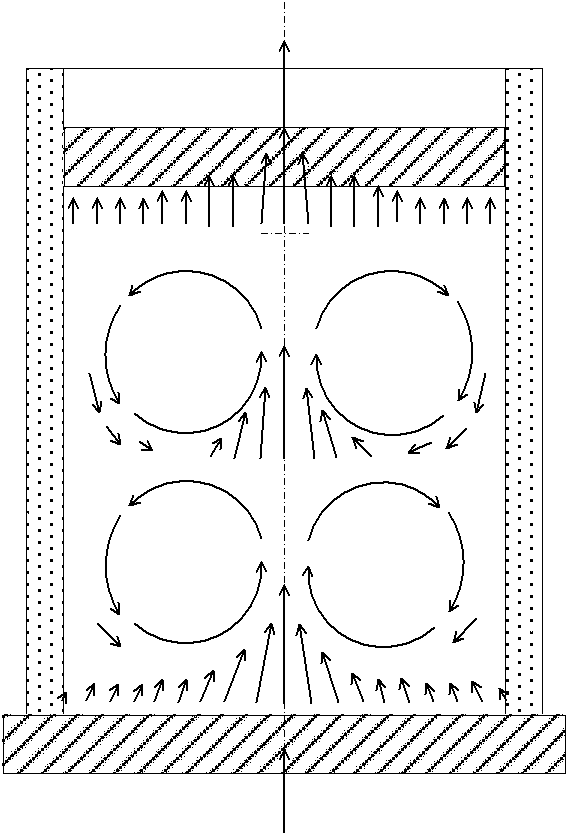

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

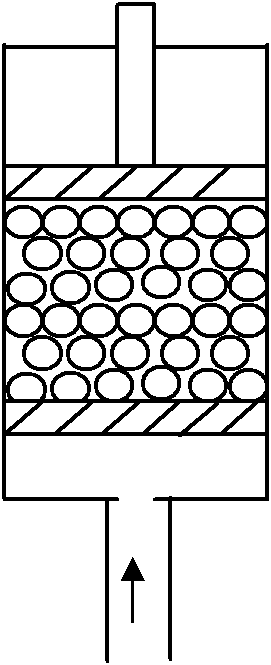

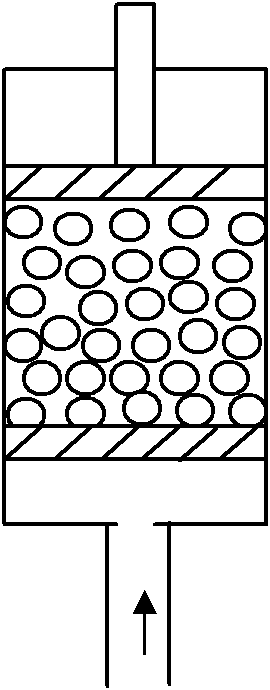

[0056] Figure 1a In the traditional chromatographic column, the adsorption resin is compressed and fixed in the chromatographic column with upper and lower porous sieve plates, so that it cannot flow, so it is called "fixed bed".

[0057] The characteristic of the traditional fixed bed is that due to the small void ratio of the bed, the resistance of the fluid passing through the bed is relatively large, the fluid flows through the bed in the form of plug flow, and the fluid velocity in the radial direction is well distributed.

[0058] However, the fixed-bed chromatographic separation column cannot directly process the feed liquid containing solids due to clogging, for example, the target product cannot be directly separated from the high-viscosity feed liquid containing cells or cell debris; because the solid substances in the feed liquid will gather in the fine In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com