Plasma processing apparatus, plasma processing method, and electronic device manufacturing method

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve the problems of decreased processing speed, increased thermal influence, and deteriorated controllability of plasma processing, and achieves the effect of improving ignition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be illustrated with reference to the drawings. However, the same reference numerals are assigned to the same constituent elements in the respective drawings, and detailed descriptions are appropriately omitted.

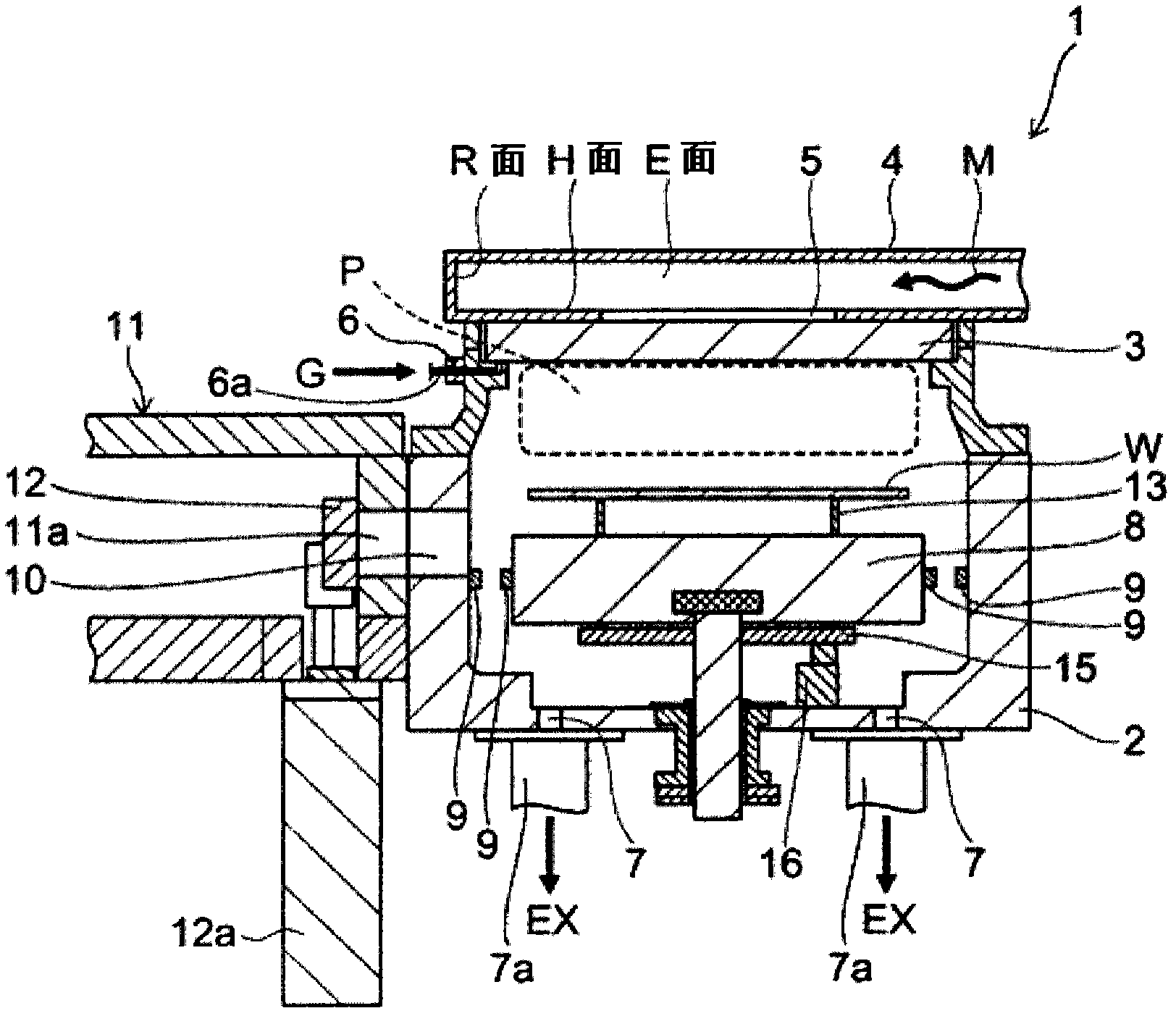

[0021] figure 1 It is a schematic diagram for illustrating a plasma processing apparatus according to an embodiment of the present invention. Such as figure 1 As shown, a substantially cylindrical processing container 2 is provided in a plasma processing apparatus 1 . The processing container 2 can maintain an environment reduced in pressure compared to the atmosphere. Furthermore, the processing container 2 is formed of metal materials such as stainless steel and aluminum alloy.

[0022] An opening is provided in the upper portion of the processing container 2, and a dielectric window 3 is provided in the opening. The dielectric window 3 is formed of a dielectric material such as quartz glass or alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com