Advanced planning and scheduling system

A planning and scheduling technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as few detailed discussions, detailed production scheduling bottlenecks, etc., to improve the overall management level, improve market adaptability, and improve management. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

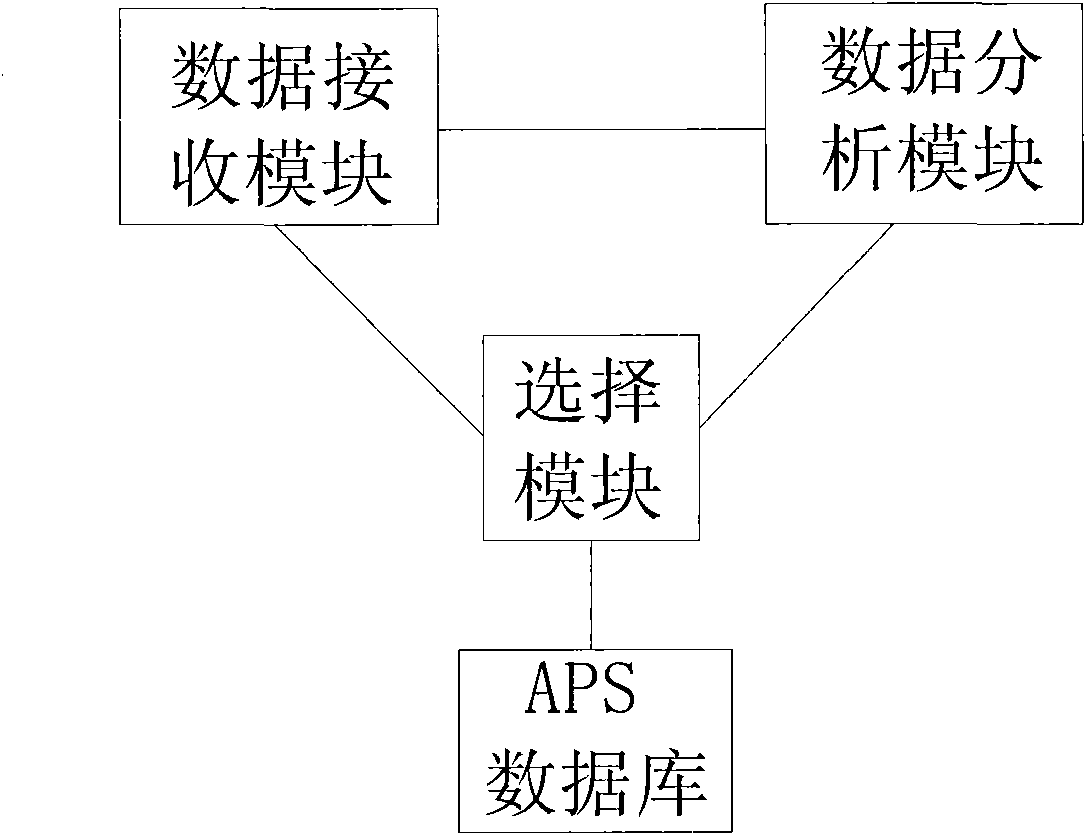

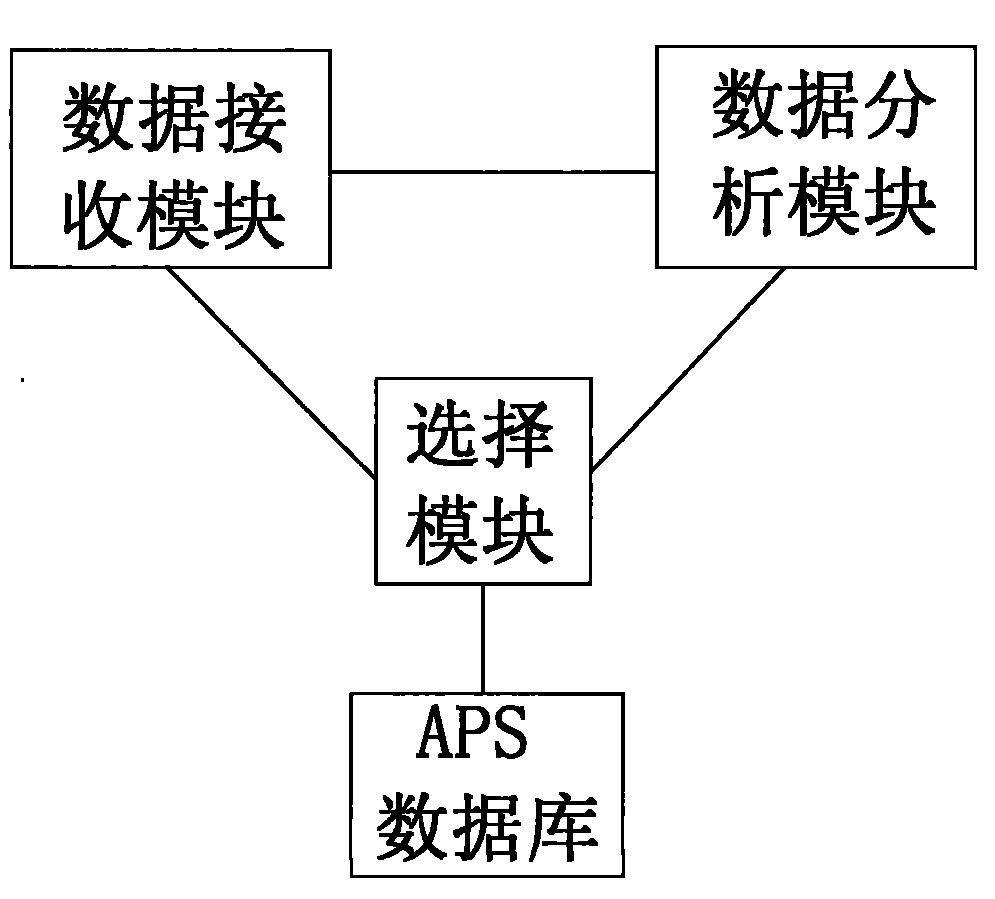

[0027] It includes a selection module, a data receiving module, and a data analysis module, and the selection module, the data receiving module, and the data analysis module are respectively connected to each other.

[0028] The system also includes an APS database, and the APS database is connected with the data receiving module.

[0029] Taking the home appliance industry of a discrete manufacturing enterprise as an example, how to effectively carry out advanced planning and scheduling according to different production modes and under the premise that outsourced materials are not the bottleneck resources of enterprise scheduling:

[0030] Find the bottleneck process through the process model: the model of the factory has an inherent process model, and the model defines the process that the model goes through.

[0031] For washing machines and air-conditioning home appliances, the product differentiation is small, and the bottleneck process is not in the previous process. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com