Method for constructing carbon footprint monitoring model for cotton products

A construction method, carbon footprint technology, applied in the field of textile weaving, can solve immaturity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Embodiment 1: A method for building a carbon footprint monitoring model for cotton products, comprising the following steps:

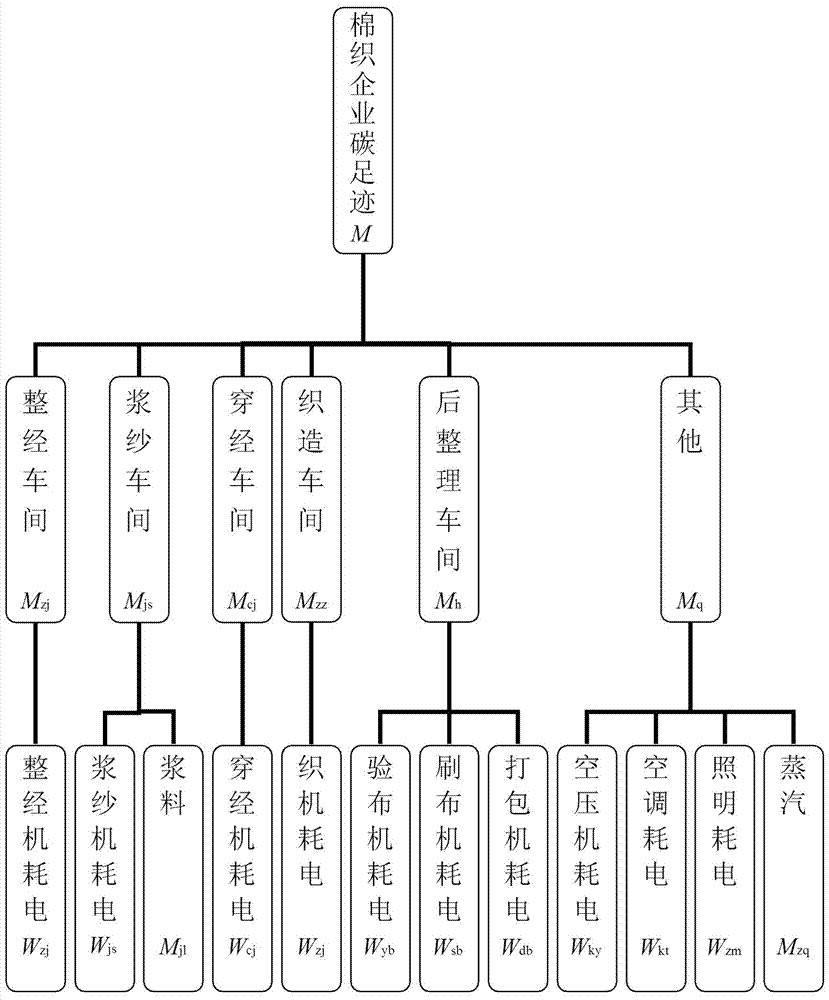

[0102] (1) Schematic diagram of the carbon footprint of each workshop in a cotton weaving enterprise, see figure 1 , mainly includes three parts: power consumption, size consumption and steam consumption. Among them, the power consumption of each process includes: power consumption of warping machine, power consumption of sizing machine, and power consumption of drawing-in machine , Power consumption of looms, power consumption of cloth inspection machines, power consumption of cloth brushing machines, power consumption of balers, power consumption of air compressors, power consumption of air conditioners and power consumption of lighting.

[0103] (2) Determine the power consumption conversion rate Z of the weaving process of the gray cloth of the cotton product to be tested, that is, the ratio of the power consumption quota of the gray cloth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com