Method for preparing immobilized metal ion affinity chromatographic monolithic column

An immobilized metal and monolithic column technology is applied in the field of preparation of immobilized metal ion affinity chromatography materials, can solve problems such as loss, and achieve the effects of low cost, strong acid and alkali resistance, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

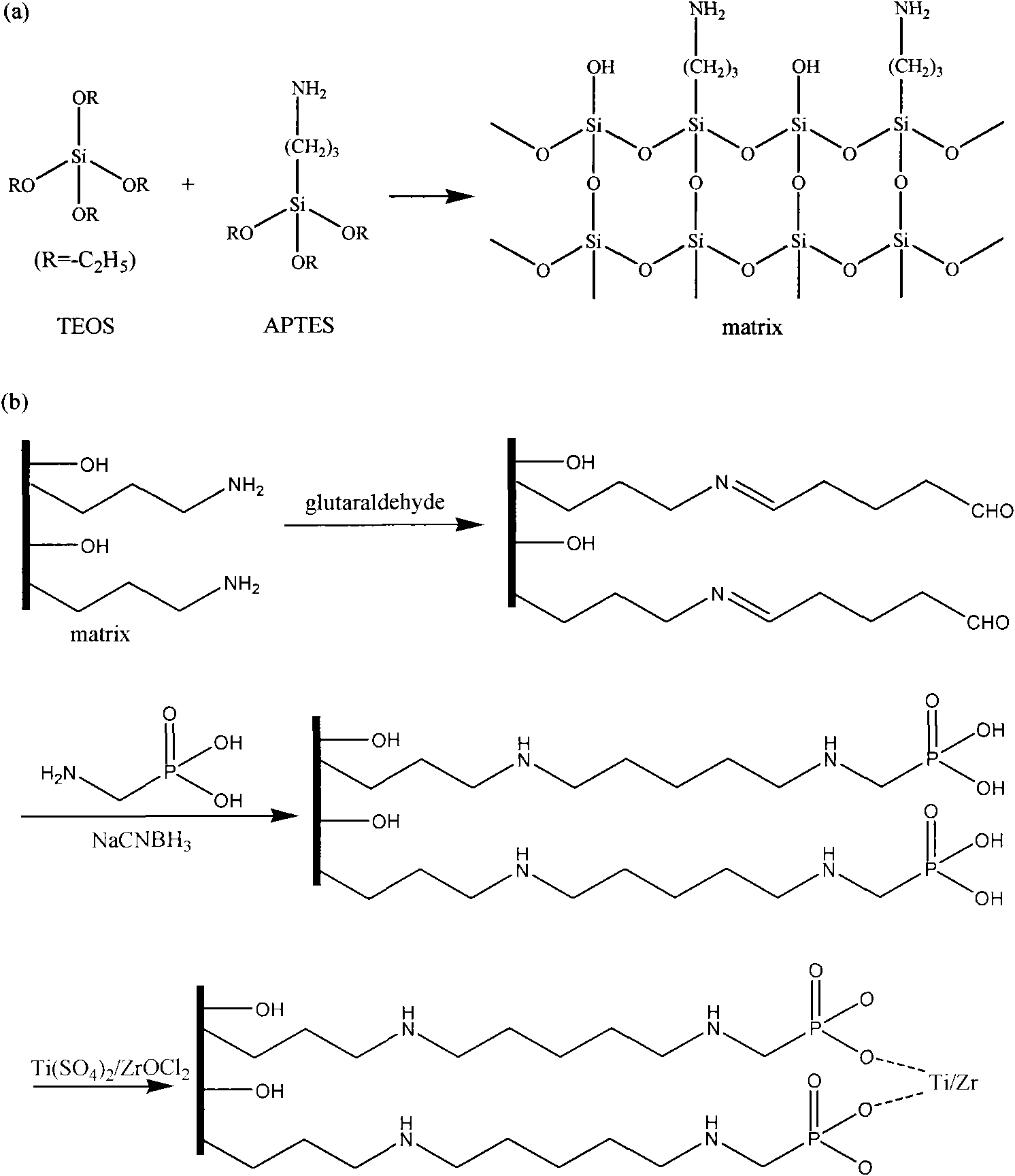

[0025] Follow the steps below to prepare an immobilized metal ion affinity chromatography column.

[0026] 1) Modification of chelating groups: Add 2 mg / mL AMPA and 5 mg / mL cyano-sodium borohydride NaCNBH 3 100 mM phosphate buffer (pH 8.0) was pumped into the column and reacted at room temperature for 6 hours. The monolithic column carrier with surface-modified phosphoric acid chelating groups can be prepared. The specific parameters of the synthesis example are shown in Table 1 below.

[0027] 2) Immobilization of metal ions: containing 20-100mM Ti(SO 4 ) 2 The aqueous solution is reacted at room temperature for 6-24 hours; the prepared monolithic column is washed with water for 0.5-6 hours. That is, the immobilized metal ion affinity chromatography column was prepared (the specific parameters are shown in Table 1 below).

[0028] Table 1. Modification of chelating groups on the surface of monolithic materials and immobilization parameters of metal ions.

[0029] ...

Embodiment 2

[0035] The difference from Example 1 is that step 3) adopts ZrOCl in the immobilization process of metal ions 2 Aqueous solution of Ti(SO 4 ) 2 of aqueous solution. The specific parameters of the synthetic examples are shown in Table 1.

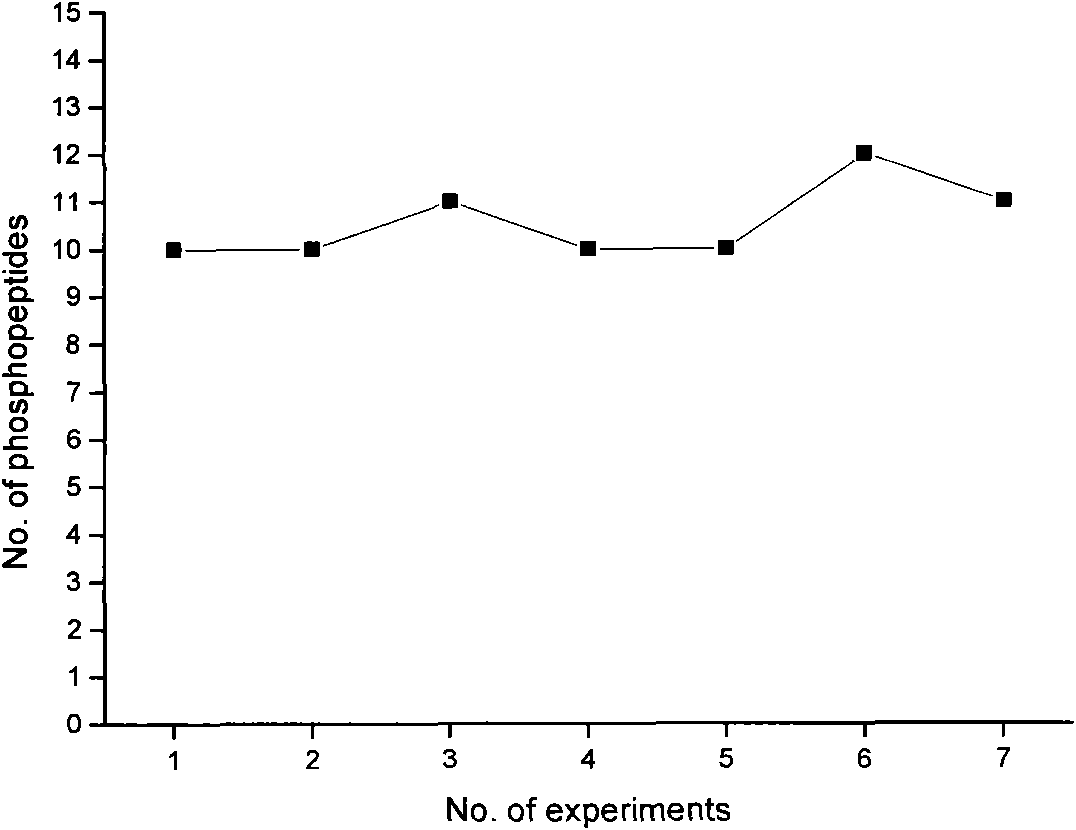

[0036] The advantages of the present invention are: good selectivity to phosphorylated peptides, reusable, large enrichment capacity, high recovery rate, simple preparation method, good permeability, low back pressure, good mechanical strength, Strong acid and alkali resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com