Negative electrode material of lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the field of electrochemistry, can solve the problems of volume effect, battery specific capacity and small room for improvement of charge and discharge performance, achieve good cycle performance, improve specific capacity and repeated charge and discharge performance, and good The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of negative electrode material:

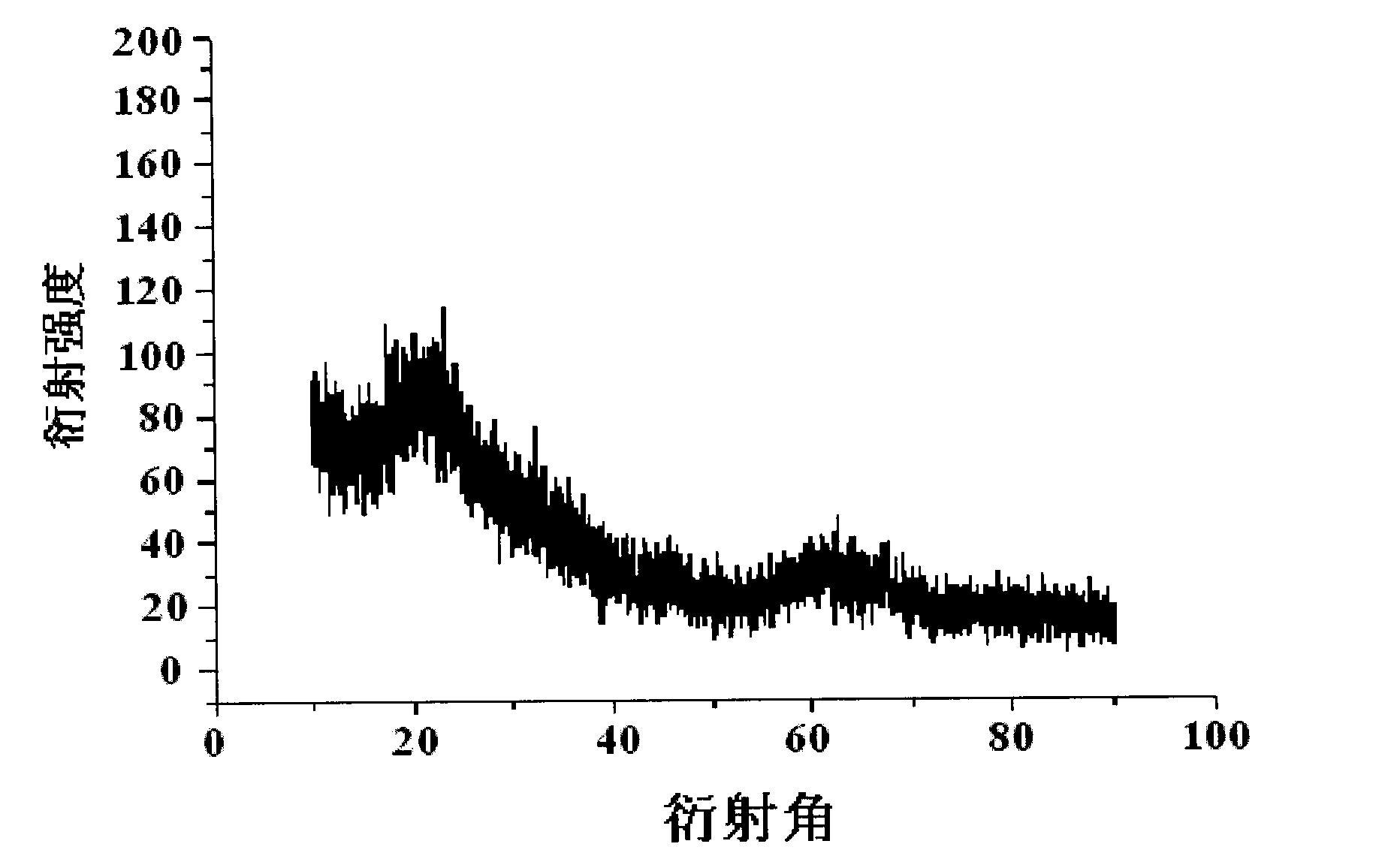

[0023] Polyacrylamide (molecular weight = 10 million) and polysiloxane (molecular weight = 60000) were mixed according to the ratio of 40:60 by weight, and then the mixture was placed in a nitrogen atmosphere at a temperature of 300 ° C for 1 hour; after cooling, The low-temperature heat-treated mixture was further cracked at a temperature of 900° C. for 1 hour in an argon atmosphere. The cracked product is crushed and passed through a 400-mesh sieve to obtain the product. figure 1 is the SEM photograph of the synthesized product. From figure 1 It can be seen that the morphology of the obtained product is irregular. figure 2 is the XRD spectrum of the product. figure 2 There are neither the diffraction peaks of silicon grains nor the diffraction peaks of graphitic carbon, indicating that each component exists in an amorphous form and belongs to an amorphous structure.

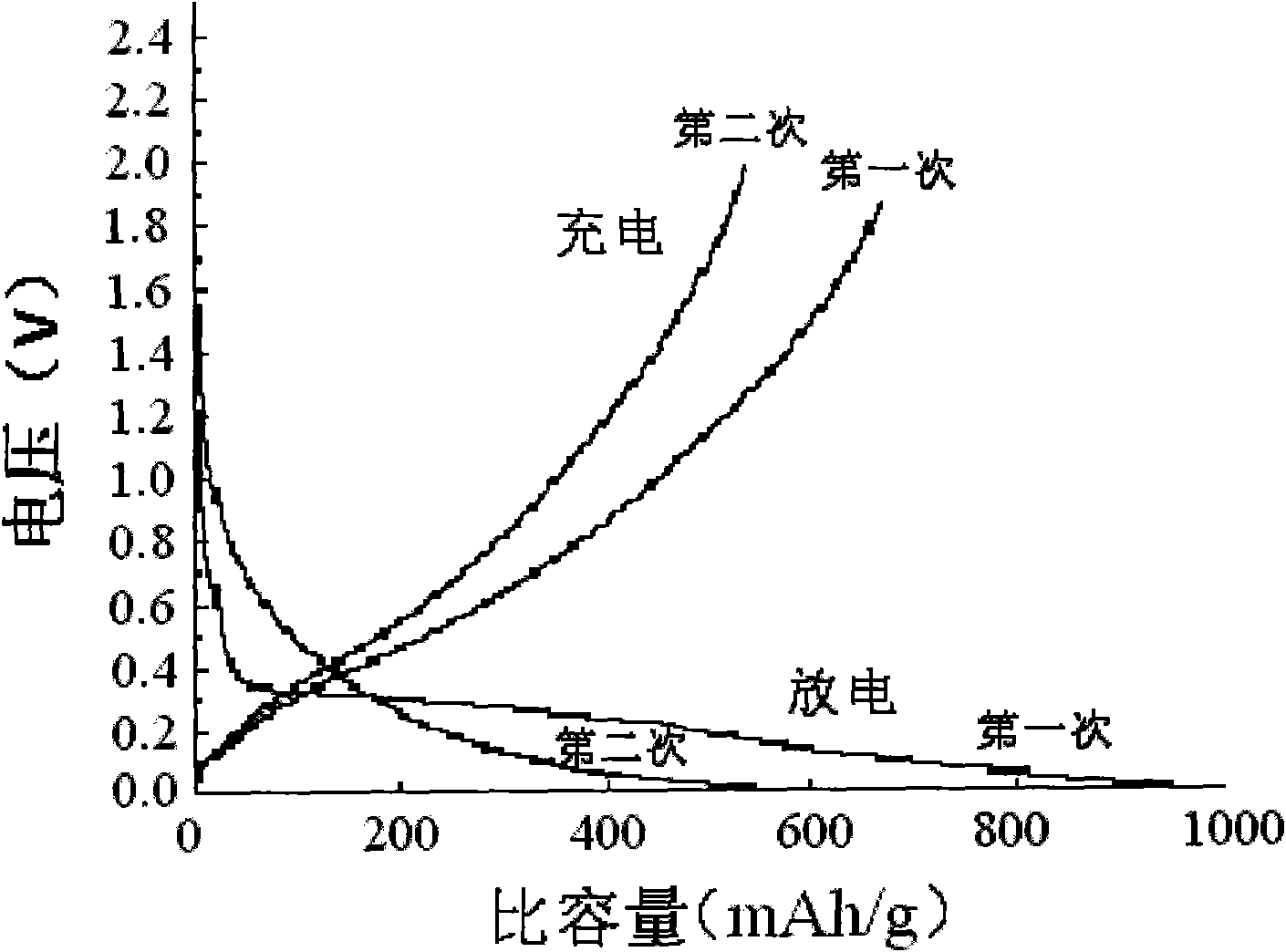

[0024] Electrode preparation: the resulting prod...

Embodiment 2

[0028] Negative material preparation:

[0029] Polyacrylamide (molecular weight = 10 million) and polysiloxane (molecular weight = 60000) were mixed according to the ratio of 50:50 by weight, and then the mixture was placed in a nitrogen atmosphere at a temperature of 300 ° C for heat treatment for 1 hour; after cooling, The low-temperature heat-treated mixture was further cracked at a temperature of 1100° C. for 1 hour in an argon atmosphere. The cracked product is crushed and passed through a 400-mesh sieve to obtain the product. XRD test shows that the product belongs to amorphous structure.

[0030] Electrode performance test:

[0031] According to the same electrochemical test method as in Example 1, the first lithium intercalation capacity of the material was 990mAh / g, the reversible delithiation capacity was 684mAh / g, and the first coulombic efficiency was 69%. After 10 cycles, the reversible delithiation capacity is 540mAh / g, which is 78.9% of the initial capacity. ...

Embodiment 3

[0033] Negative material preparation:

[0034]Polyacrylamide (molecular weight = 10 million) and polysiloxane (molecular weight = 60000) were mixed according to the ratio of 10:90 by weight, and then the mixture was placed in a nitrogen atmosphere at a temperature of 200 ° C for 10 hours; after cooling, The low-temperature heat-treated mixture was further cracked at a temperature of 800° C. for 15 hours in an argon atmosphere. The cracked product is pulverized and passed through a 500-mesh sieve to obtain an amorphous negative electrode material.

[0035] Electrode performance test:

[0036] According to the same electrochemical test method as in Example 1, the first lithium intercalation capacity of the material was 1682mAh / g, the reversible delithiation capacity was 925mAh / g, and the first coulombic efficiency was 55%. After 10 cycles, the reversible delithiation capacity is 470mAh / g, which is 57% of the initial capacity. The reversible capacity of the material is higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com