White light LED (light-emitting diode) and packaging method thereof

A packaging method and LED chip technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of accelerating the light decay of phosphor powder in white LEDs, shortening the life of LED light-emitting devices, and aging, so as to improve the service life and enhance Stability, the effect of lowering the heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

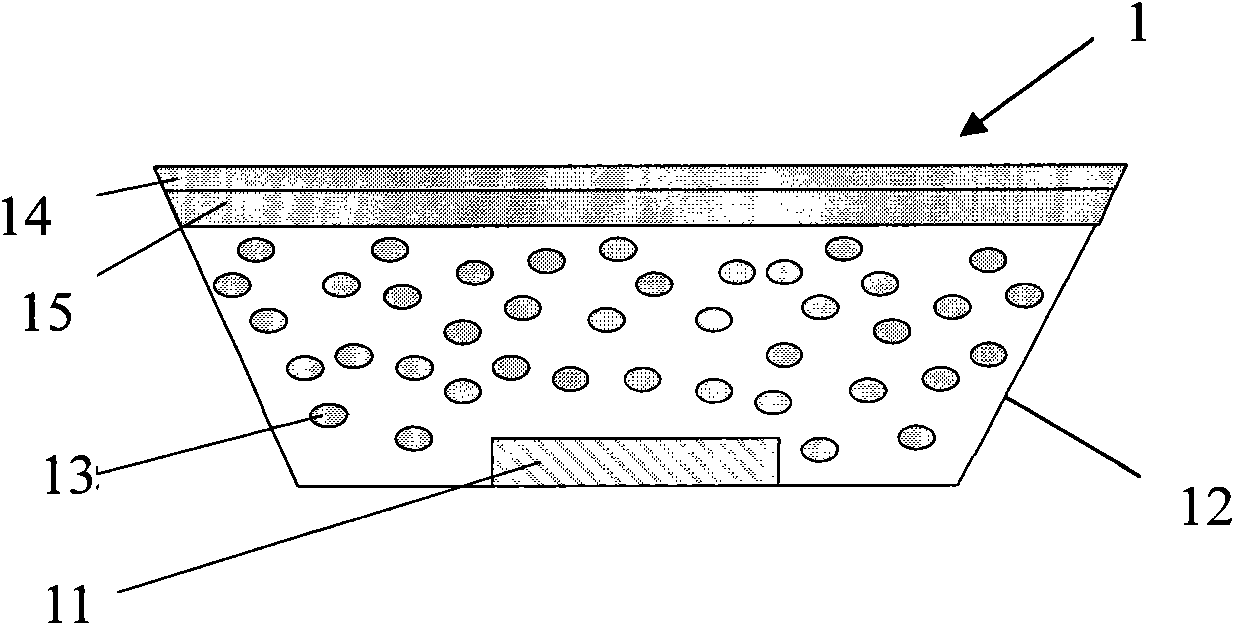

[0035] Such as figure 2 Shown is a cross-sectional view of Embodiment 1 of the present invention. figure 2 The packaging of the white LED 1 shown is to fix a blue LED chip 11 with a wavelength of 455nm on the base 12; then coat the blue LED chip 11 with cerium-doped yttrium aluminum garnet (YAG:Ce 3+ ) phosphor glue 13; then a common glass 14 coated with an AlN film 15 with a thickness of 50nm is covered on the phosphor glue 13, and it is not coated with the other surface of the AlN film 15 with the phosphor glue 13 closely fit together to obtain a semi-finished LED product; then, move the semi-finished LED product to an oven and keep it warm at 120°C for 2 hours to cure the fluorescent powder glue 13, and then keep it warm at 150°C for 2 hours to completely solidify the phosphor powder glue 13 ,get figure 2 White LED 1 shown.

Embodiment 2

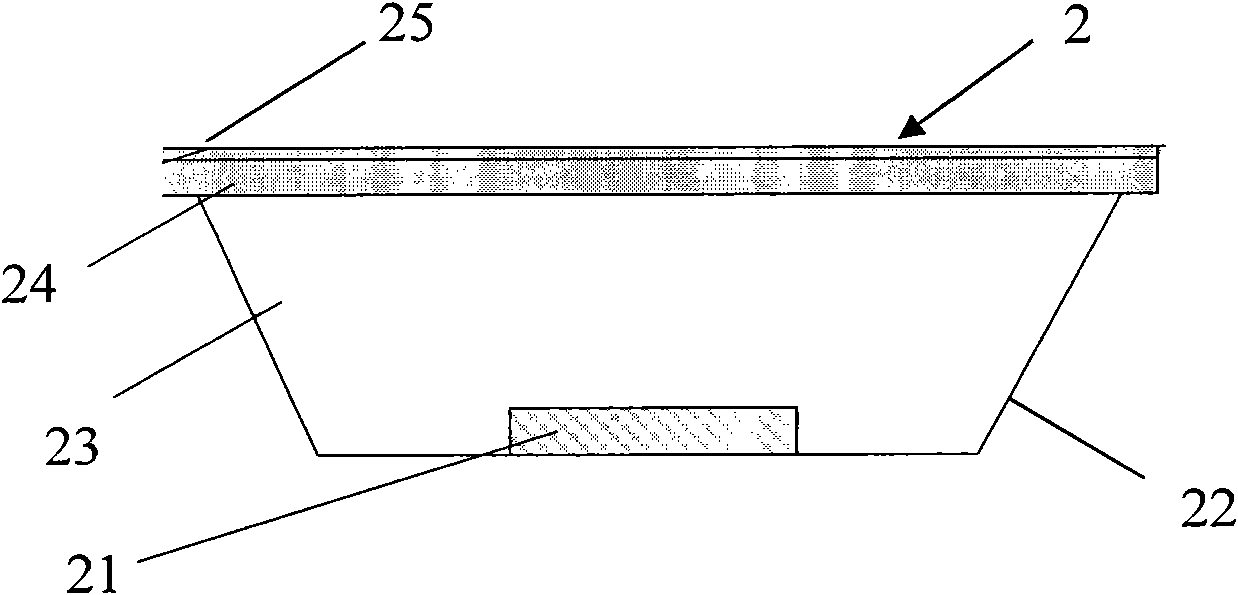

[0037] Such as image 3 Shown is a cross-sectional view of Embodiment 2 of the present invention. image 3 The packaging of the white LED 2 shown is to fix a blue LED chip 21 with a wavelength of 480nm on the base 22; then coat the blue LED chip 21 with organic transparent silica gel 23; The luminescent glass 24 that can emit yellow light of the film 25 is covered on the organic transparent silica gel 23, and the other surface that is not coated with the BN film 25 is closely attached to the organic transparent silica gel 23 to obtain the LED semi-finished product; subsequently, the The LED semi-finished product was moved to an oven, and kept at 100°C for 3 hours to solidify the organic transparent silica gel 23, and then kept at 170°C for 1 hour to completely solidify the organic transparent silica gel 23 to obtain image 3 White LED 2 shown.

Embodiment 3

[0039] like Figure 4 Shown is a cross-sectional view of Embodiment 3 of the present invention. Figure 4 The packaging of the white LED 3 shown is to fix a purple LED chip 31 with a wavelength of 320nm on the base 32; then coat the organic transparent silica gel 33 on the purple LED chip 31; The luminescent glass 34 of the diamond film 35 that can emit white light under the excitation of 365nm light is covered on the organic transparent silica gel 33, and the other surface that is not coated with the transparent diamond film 35 is closely attached to the organic transparent silica gel 33 to obtain LED semi-finished products; subsequently, the LED semi-finished products are moved to an oven, and kept at 130°C for 1 hour to solidify the organic transparent silica gel 33, and then kept at 140°C for 5 hours to completely solidify the organic transparent silica gel 33 to obtain Figure 4 White LED 3 shown.

[0040] In summary, the white light LED of the present invention and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com