Miniaturized ammonia water absorption refrigerator

An absorption refrigerator and refrigerator technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large volume, low thermal efficiency, heavy weight, etc., achieve high thermal conductivity, improve thermal conductivity, and small specific gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

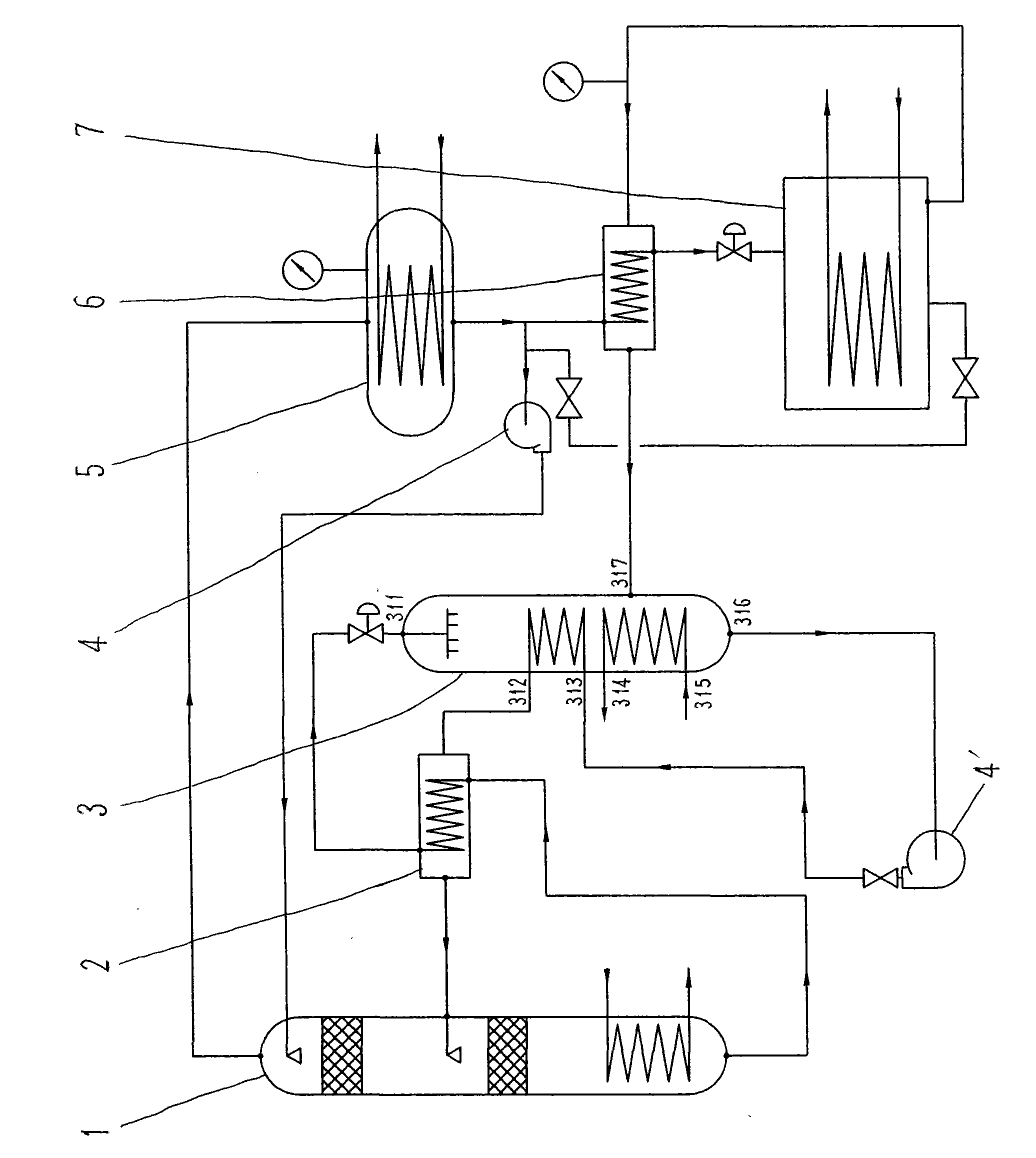

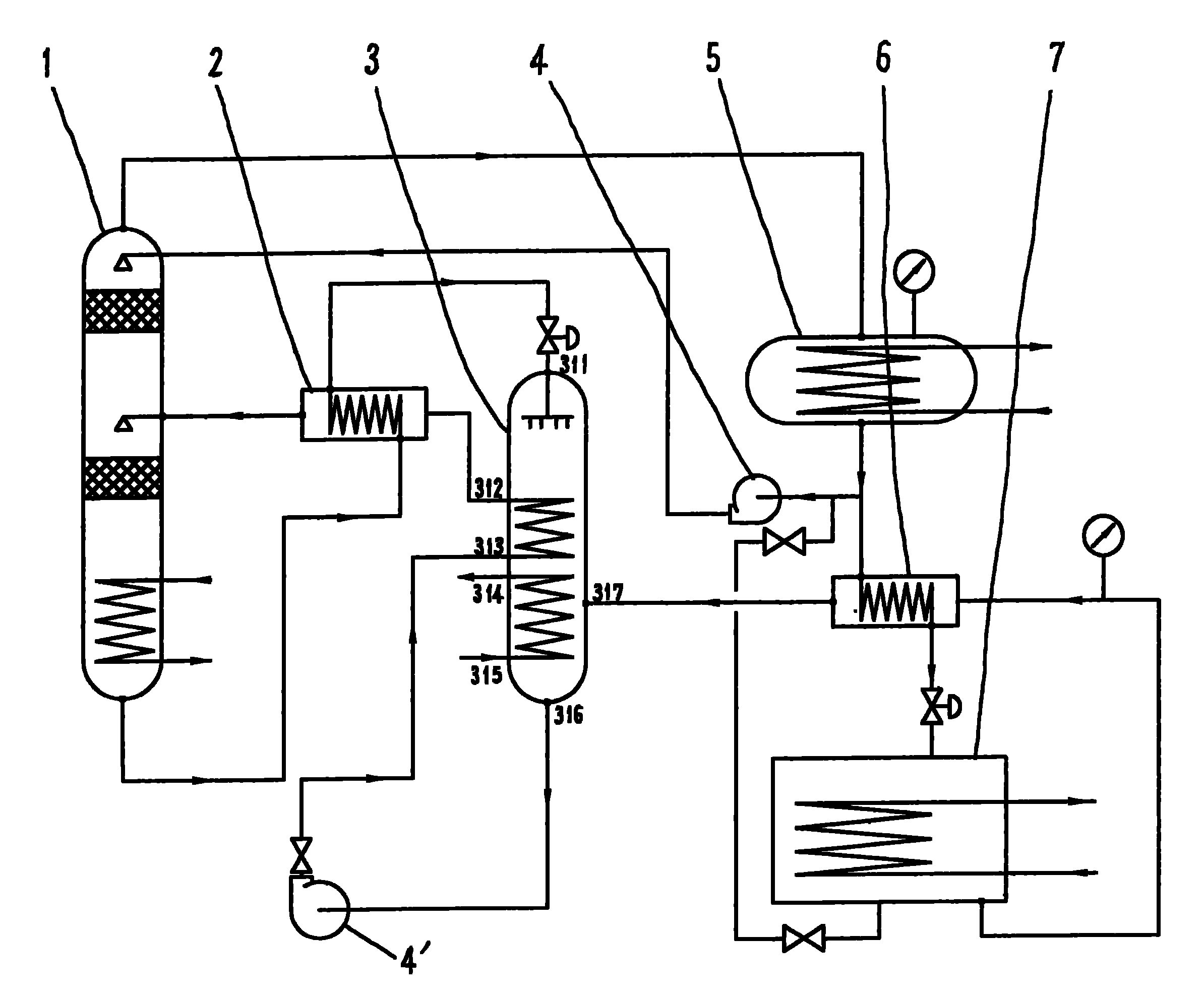

[0010] refer to figure 1 The miniaturized ammonia water absorption refrigerator includes a generator 1, a solution heat exchanger 2, an absorber 3, an ammonia pump 4, a condenser 5, a subcooler 6 and an evaporator 7. The overall structure of the unit is basically the same as that of the existing one. There are similar techniques, among which:

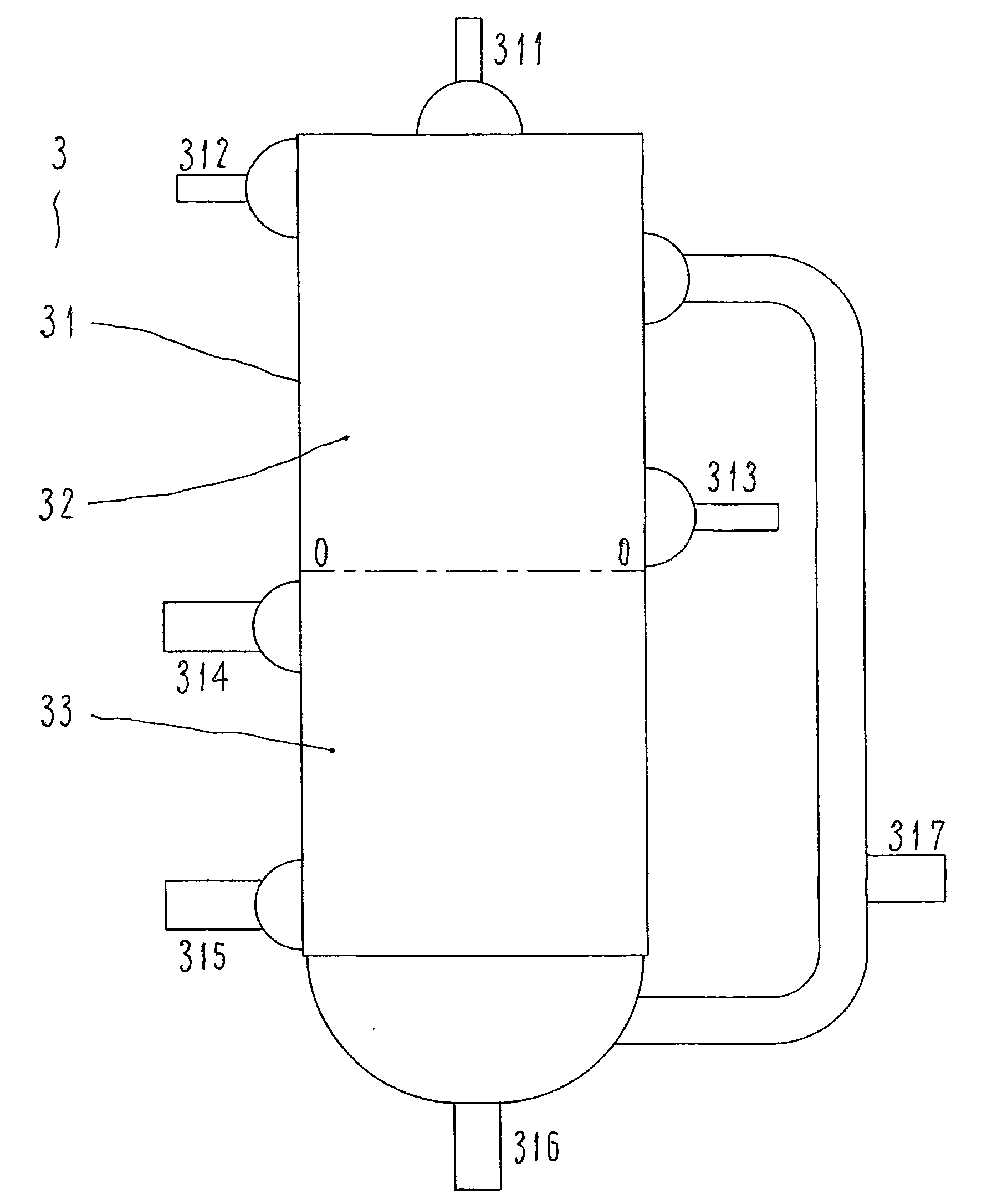

[0011] Absorber 3, as shown in the figure, the inner cavity of the box body 31 of the absorber 3 forms a combined structure, that is, a GAX absorber 32 is arranged above the interface 0-0 of the inner cavity of the box body 31, and is arranged below the interface 0-0 Cooling water absorber 33 is arranged, and each interface 311,312,313,314,315,316,317 is also respectively provided with on casing 31, and interface 311 is the dilute solution inlet that solution heat exchanger 2 sends (as figure 1 ), the interface 312,313 is the outlet and the import from the ammonia pump 4' concentrated solution; the interface 314,315 is the outlet and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com