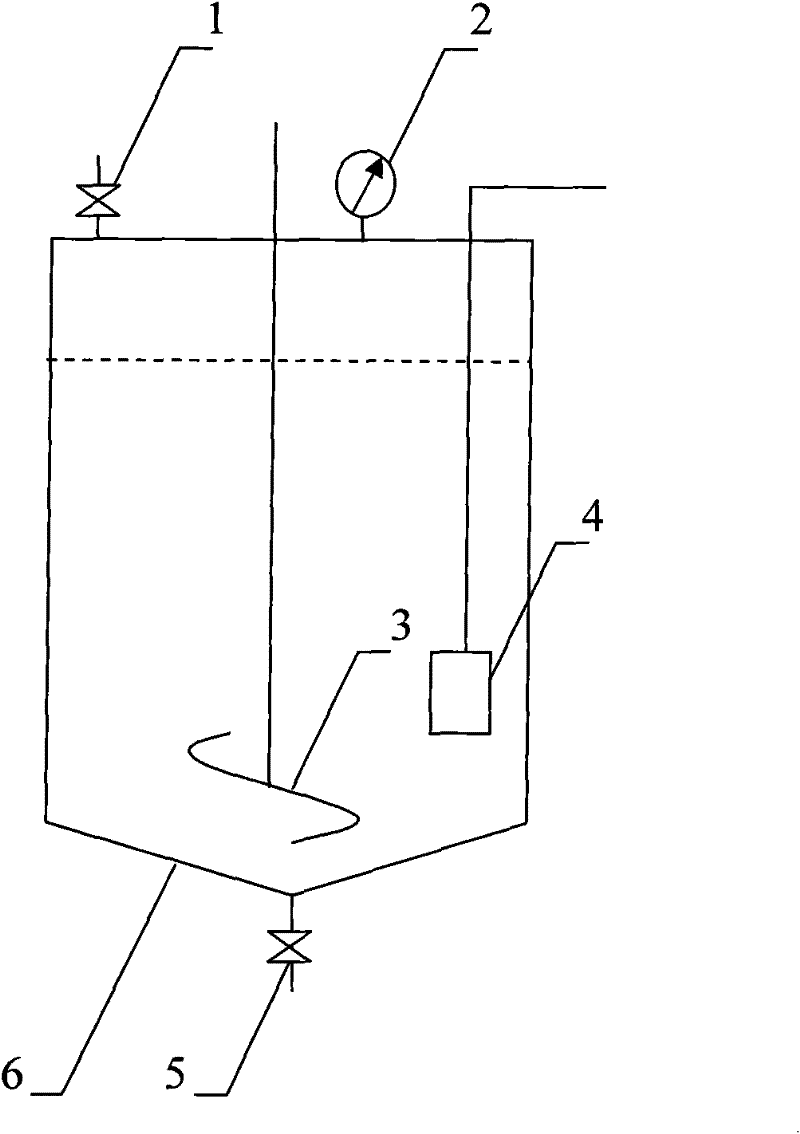

Embedded ultrasonic deaeration device and deaeration process

A built-in, defoaming technology, used in spinning solution defoaming, spinning solution filtration, fiber processing, etc., can solve problems such as high energy consumption, long time, fiber damage, etc., to ensure product fiber quality, defoaming The effect of shortened time and shortened dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Design an ultrasonic defoaming device, the ultrasonic frequency of its ultrasonic generator 4 is designed to be 20kHz, and the ultrasonic power is designed to be 100W.

[0023] Use the above-mentioned defoaming device to prepare polysulfone hollow fibers by solution spinning: open the feed valve 1, and add materials such as polysulfone resin, solvent and additives with a total amount of 10 kg into the material-dissolving tank 6 according to the known process design, Close the feed valve 1; open the agitator 3 and the ultrasonic generator 4, and set the spinning temperature to the temperature of the spinning solution in the melting material tank 6; stir and simultaneously ultrasonically deaerate for 0.5h and then close the agitator 3, Continue defoaming for 5 minutes by ultrasonic waves until the bubbles in the solution completely disappear, and then turn off the ultrasonic generator 4 to obtain a completely defoamed and uniformly dissolved spinning solution. The resulti...

Embodiment 2

[0025] Design an ultrasonic defoaming device, the ultrasonic frequency of its ultrasonic generator 4 is designed to be 100kHz, and the ultrasonic power is designed to be 900W.

[0026] Use the above-mentioned defoaming device to prepare polyvinylidene fluoride hollow fibers by solution spinning: open the feed valve 1, and add materials such as polyvinylidene fluoride resin, solvent and additives with a total amount of 20kg to the solvent according to the known process design In the tank 6, close the feed valve 1; turn on the stirring 3 and the ultrasonic generator 4, and set the spinning temperature to the temperature of the spinning solution in the melting material tank 6; stir and at the same time ultrasonic degassing for 1 hour, then close the stirring 3 , using ultrasonic waves to continue defoaming for 15 minutes until the bubbles in the solution completely disappear, and then turn off the ultrasonic generator 4 to obtain a completely defoamed and uniformly dissolved spinn...

Embodiment 3

[0028] An ultrasonic defoaming device is designed, the ultrasonic frequency of the ultrasonic generator 4 is designed to be 200kHz, and the ultrasonic power is designed to be 5000W.

[0029] Use the above-mentioned defoaming device to prepare polyacrylonitrile hollow fibers by solution spinning: open the feed valve 1, and add materials such as polyacrylonitrile resin, solvent and additives with a total amount of 30kg into the material dissolving tank 6 according to the known process design In the process, close the feed valve 1; open the stirring 3 and the ultrasonic generator 4, and set the spinning temperature to the temperature of the spinning solution in the melting material tank 6; stir and simultaneously ultrasonic degassing for 3 hours and then close the stirring 3, use The ultrasonic wave continued to defoam for 30 minutes until the air bubbles in the solution completely disappeared, and then the ultrasonic generator 4 was turned off to obtain a completely defoamed and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com