Process and equipment for preparing anisotropic rare-earth permanent-magnet powder and product prepared thereby

A rare earth permanent magnet, anisotropic technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of magnetic powder performance loss, non-involvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

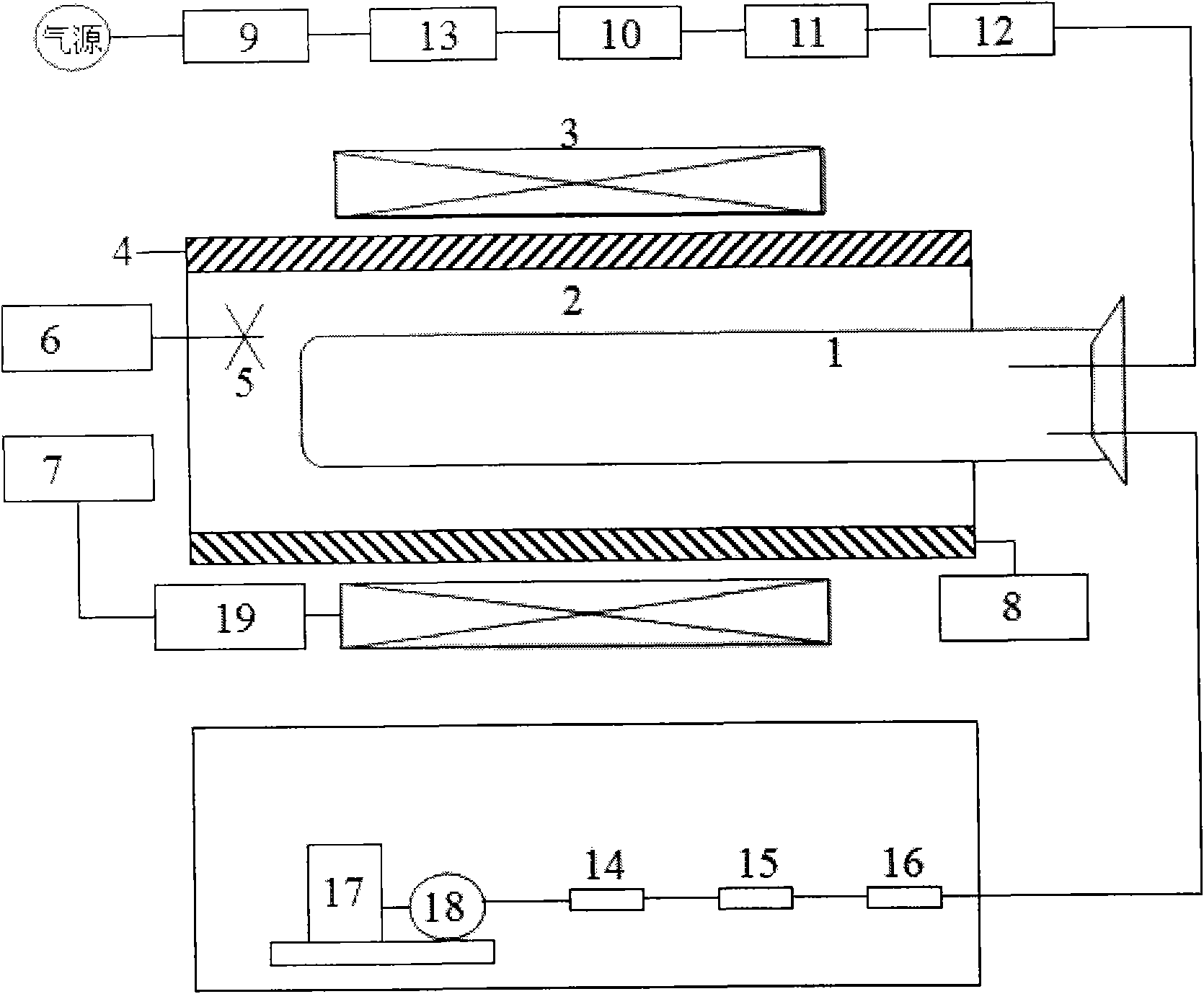

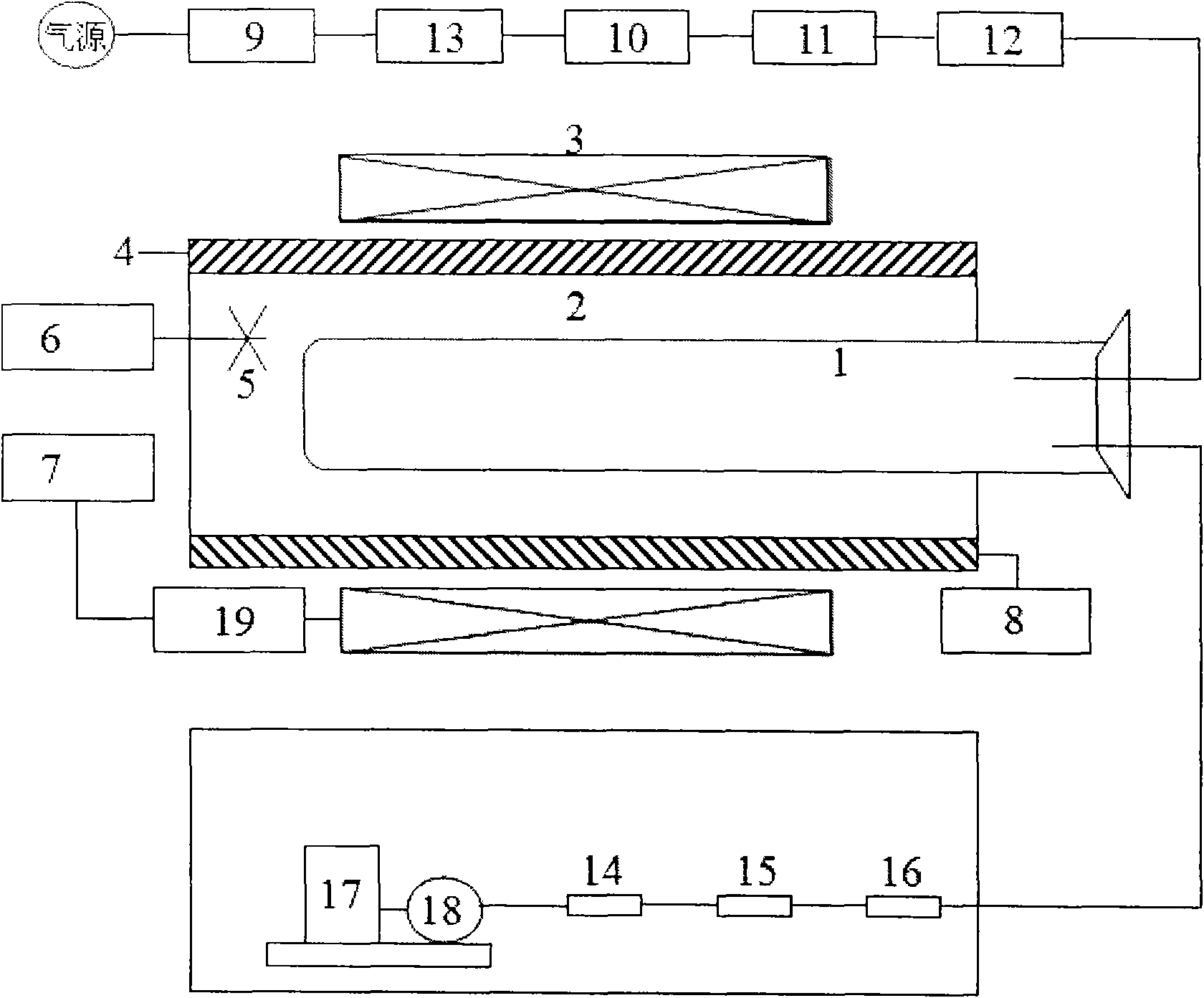

Method used

Image

Examples

Embodiment

[0058] (1) Preparation of raw materials

[0059] With the composition shown in Table 1, quantitatively weigh the raw material elements or raw material alloys, and then conduct induction melting or rapid solidification to obtain alloys after the materials are prepared, and then perform annealing treatment at a certain temperature and time under the protection of argon to make the alloy structure Uniform, coarse powder with a particle size of 5-25mm is obtained after coarse crushing and enters the equipment for hydrogen-induced reaction treatment. In Table 1, the component compositions are expressed in atomic percent.

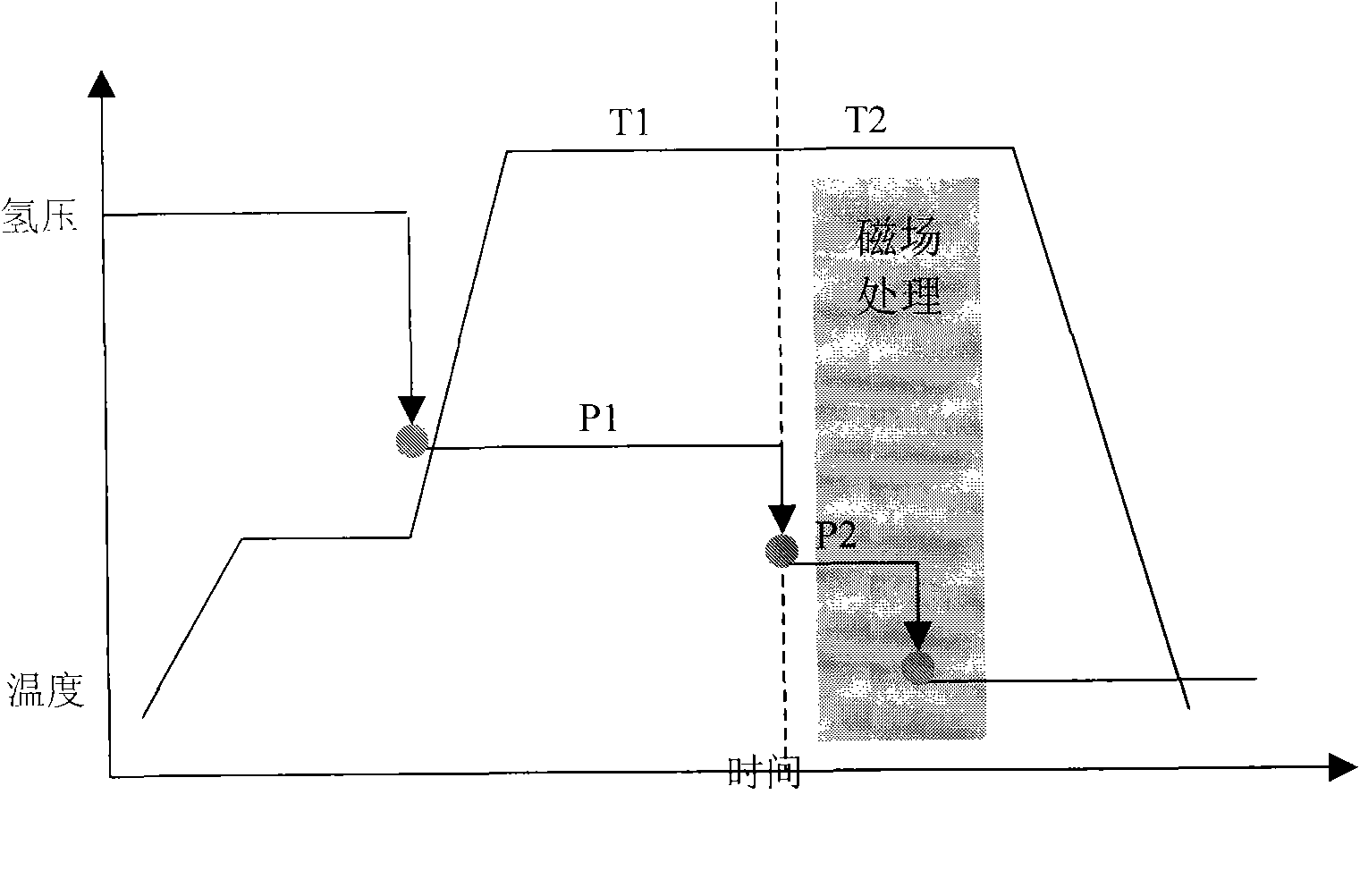

[0060] (2) Preparation of anisotropic magnetic powder

[0061] The alloys according to the composition ratio shown in Table 1 were annealed and crushed, and then treated in the hydrogen-induced reaction process.

[0062] A high-temperature hydrogen absorption process in which the alloy is treated under the condition of maintaining the hydrogen partial pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com